Dust remover of shot blasting machine

A technology of dust collector and shot blasting machine, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as easy to cause danger, pollute the air environment, and low dust removal efficiency, and achieve simple and reasonable structural design. Effects of a healthy work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

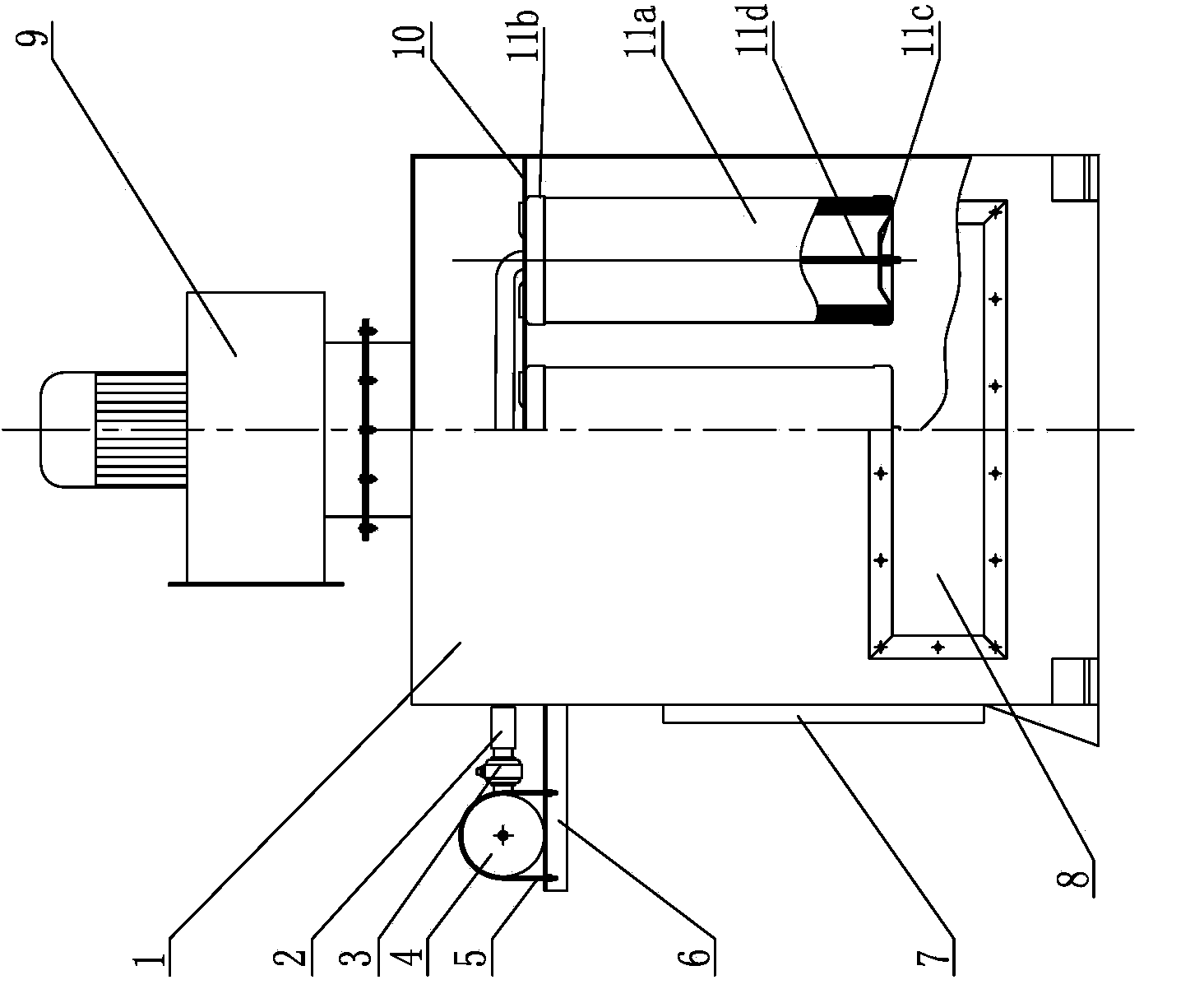

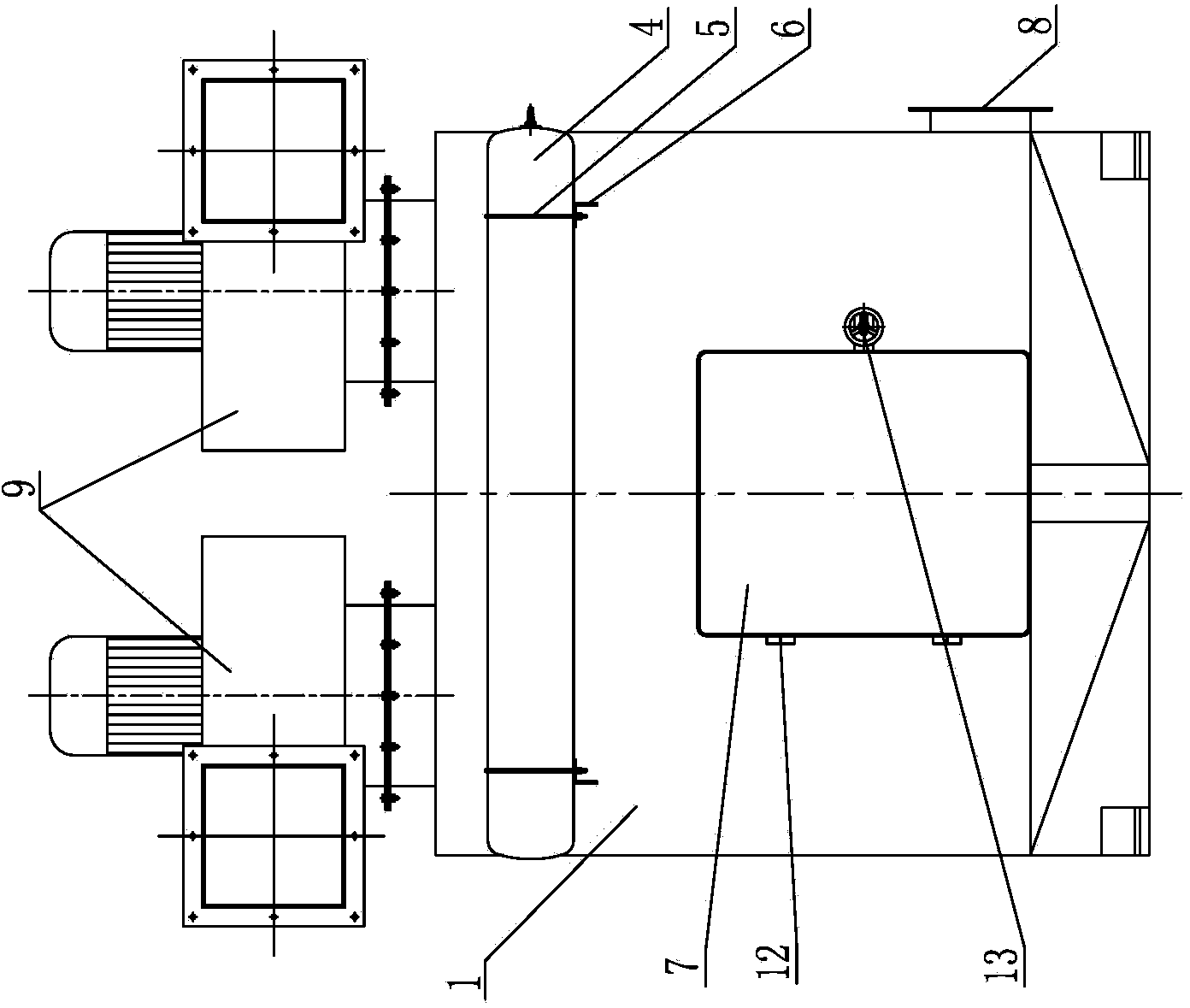

[0018] As shown in the figure: the shot blasting machine dust collector in the embodiment is mainly composed of a dust collector box 1, a connecting pipe 2, a pulse solenoid valve 3, an air storage tank 4, an annular bolt 5, a bracket 6, an inspection door 7, and a suction port 8. Dust suction fan 9, filter cartridge installation plate 10, filter cartridge 11, hinge 12 and handwheel 13 etc. are composed.

[0019] Such as figure 1 , figure 2 As shown, the side wall of the dust collector box 1 is provided with a suction port 8, and the top of the dust collector box 1 is provided with a discharge port. The port is connected to the next-level processing equipment or the outside atmosphere; the dust collector box 1 is provided with a filter cartridge mounting plate 10, and several evenly distributed filter cartridges 11 are installed on the filter cartridge moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com