A coating machine for making plastic wrap

A technology of fresh-keeping film and coating machine, applied in the field of coating machine, which can solve the problems of small contact area between PE film and film feeding roller, PE film cannot be flattened, aggravated film slipping, etc., and achieves stable and reliable coating quality, structure Simple, the effect of solving the slipping problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

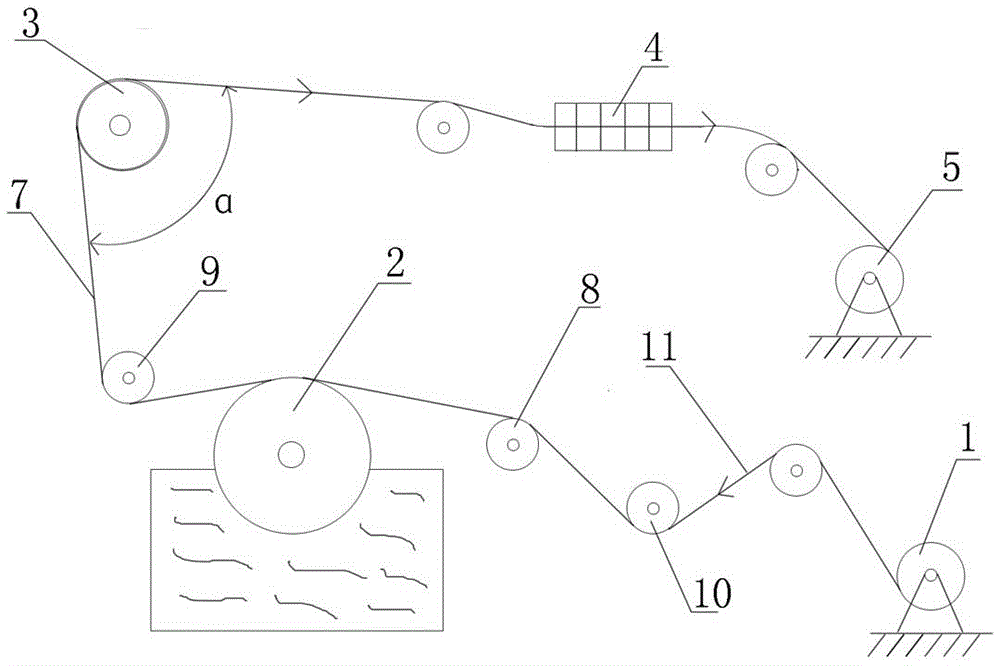

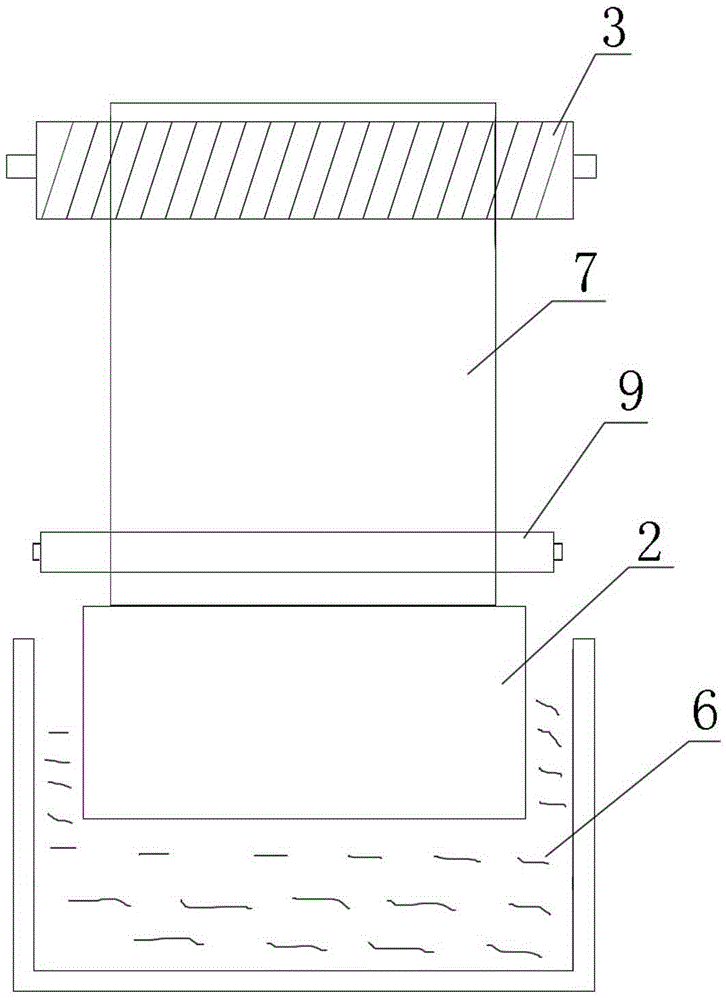

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, a kind of coating machine that is used to make fresh-keeping film according to the present invention mainly comprises: a film releasing mechanism 1 that is provided with PE film reel, at least two are placed on glue roller 2 both sides Rotating roller, a film feeding roller 3, a drying mechanism 4 and a film rolling mechanism 5; the glue application roller 2 is located on the top of the glue tank 6, and is at least partially submerged in the glue solution in the glue tank 6, through The rotation of the gluing roller 2 brings the glue in the glue tank 6 to the gluing roller 2, and the glue is applied to the surface of the PE film 7 that is closely attached to the upper surface of the gluing roller 2, and the glue is applied The PE film 7 with glue is driven by the film feeding roller 3, and enters the drying mechanism 4, so that the surface of the PE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com