Wire forming module for automatic Christmas tree tying machine

A technology for tying and loosening machines and Christmas trees, which is applied in the field of making Christmas tree automatic mechanical devices, can solve the problems of high labor intensity of operators, inability to realize automatic operation, low work efficiency, etc., and achieves reduced labor intensity, accurate molding size, and reduced labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

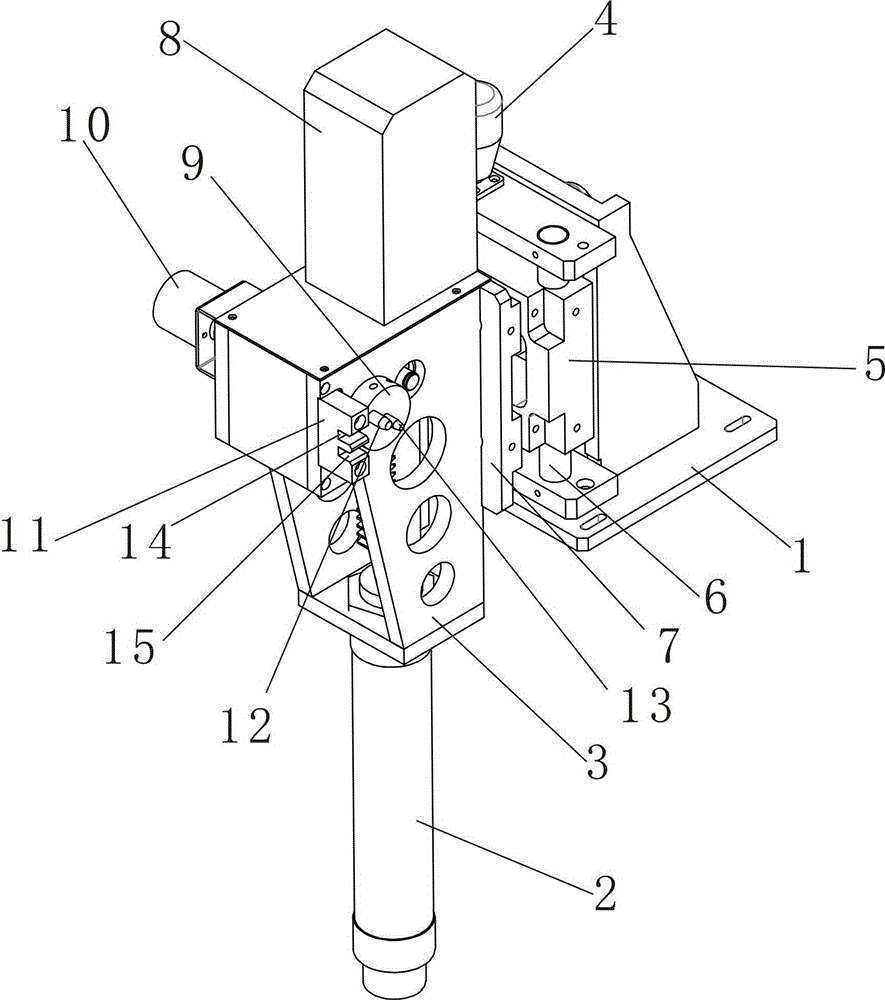

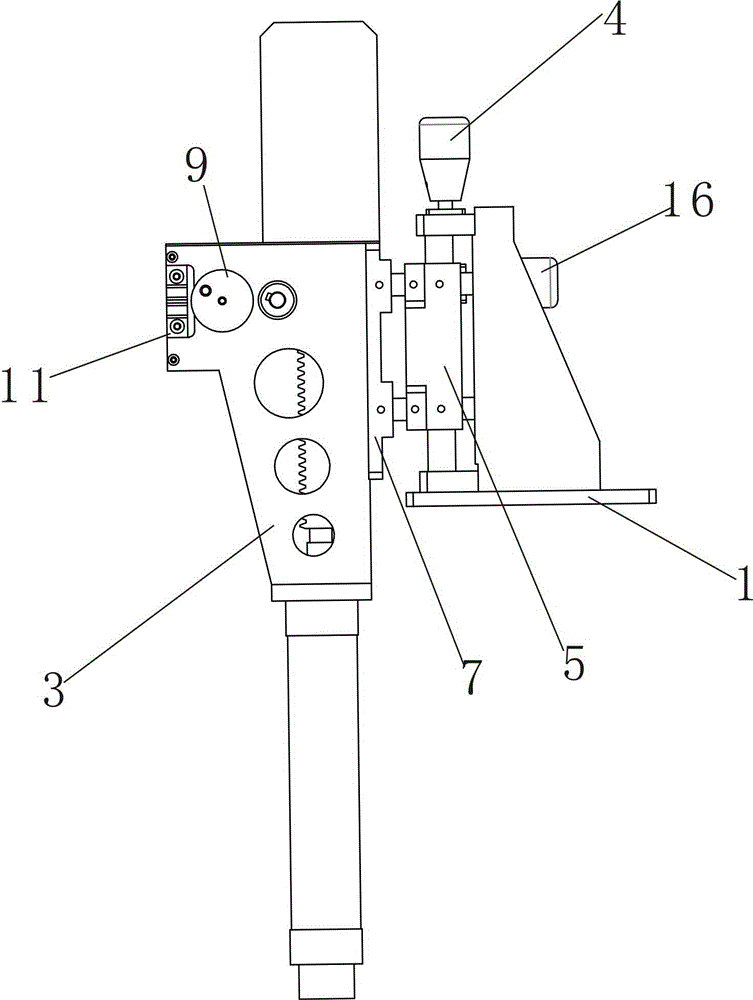

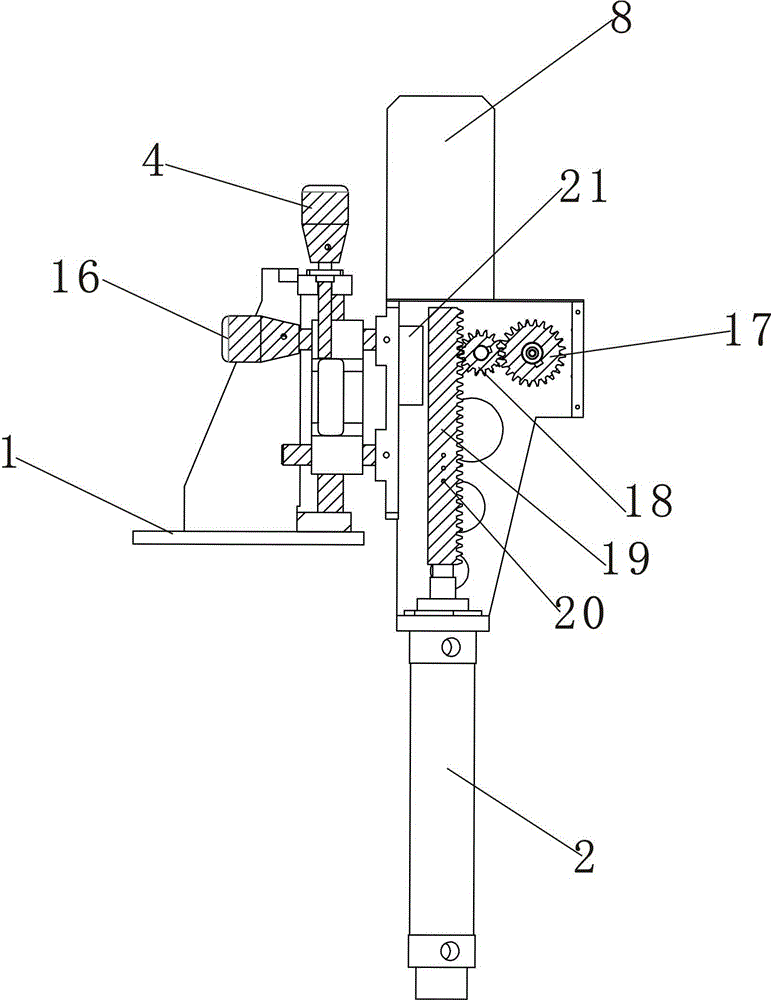

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an iron wire forming module of an automatic Christmas tree binding loosening machine includes a base 1, a power cylinder 2 and a forming fixing seat 3 arranged on the power cylinder 2, and the base 1 is provided with an up and down adjustment knob 4 and a left and right Adjustment knob 16, the upper and lower adjustment knobs 4 lower ends are connected with the cross sliding mold base 5 and the up and down adjustment guide shaft 6 passing through the cross sliding mold base 5, and the left and right adjustment knobs 16 are connected with the cross sliding mold base 5. On the right side of the forming fixed seat 3, a rotating main shaft seat 9 and a positioning card mold 11 are arranged, and an upper card slot 14 and a lower card slot 15 are arranged on the positioning card mold 11, and a rotating gear 17 is connected in the middle of the rotating main shaft seat 9, and the front end is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com