Full-automatic high-speed manufacturing method and full-automatic high-speed manufacturing device of metal packaging tank body

A technology of metal packaging cans and manufacturing methods, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., and can solve problems such as low production quality, low operating efficiency, and poor automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

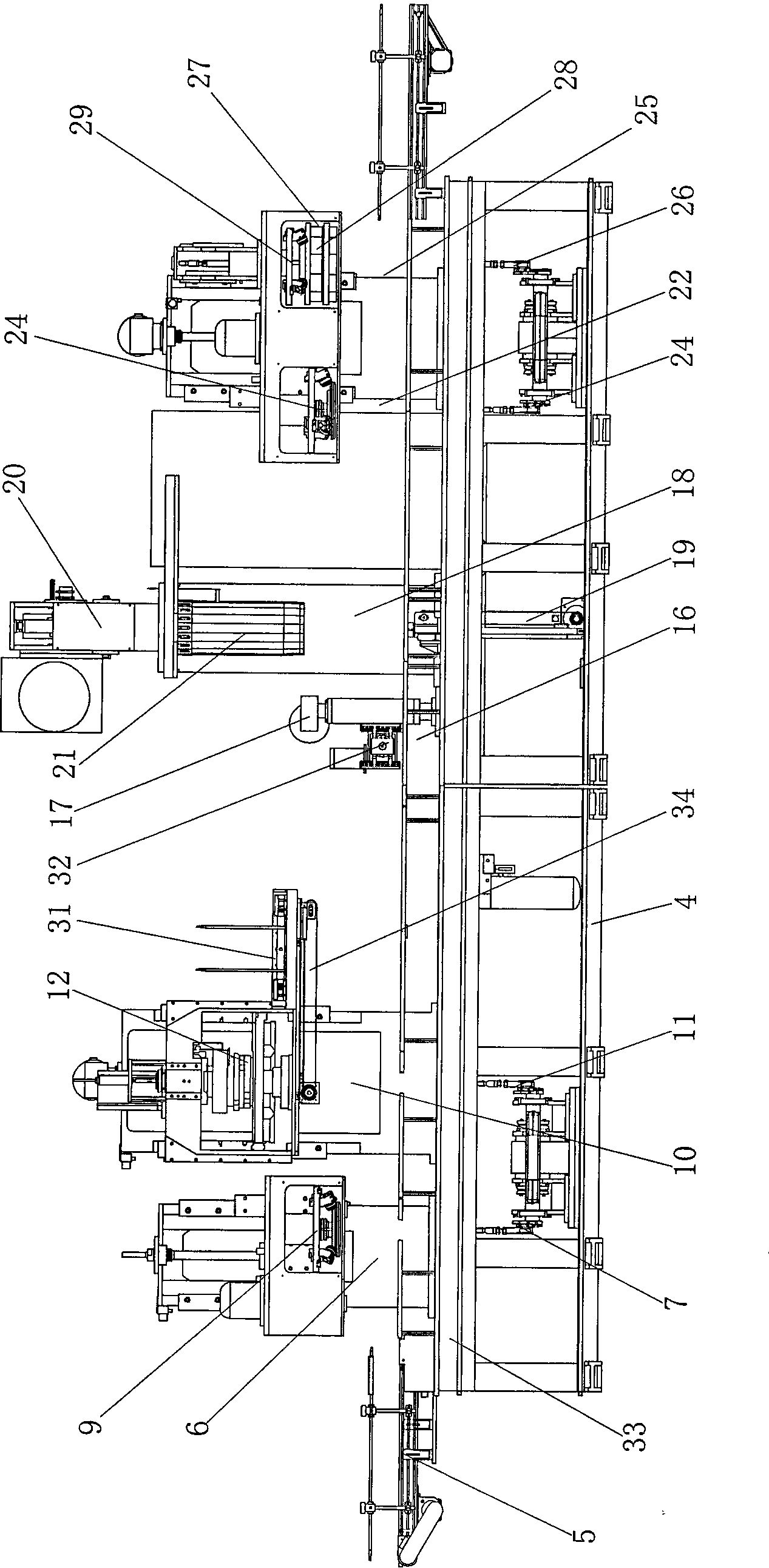

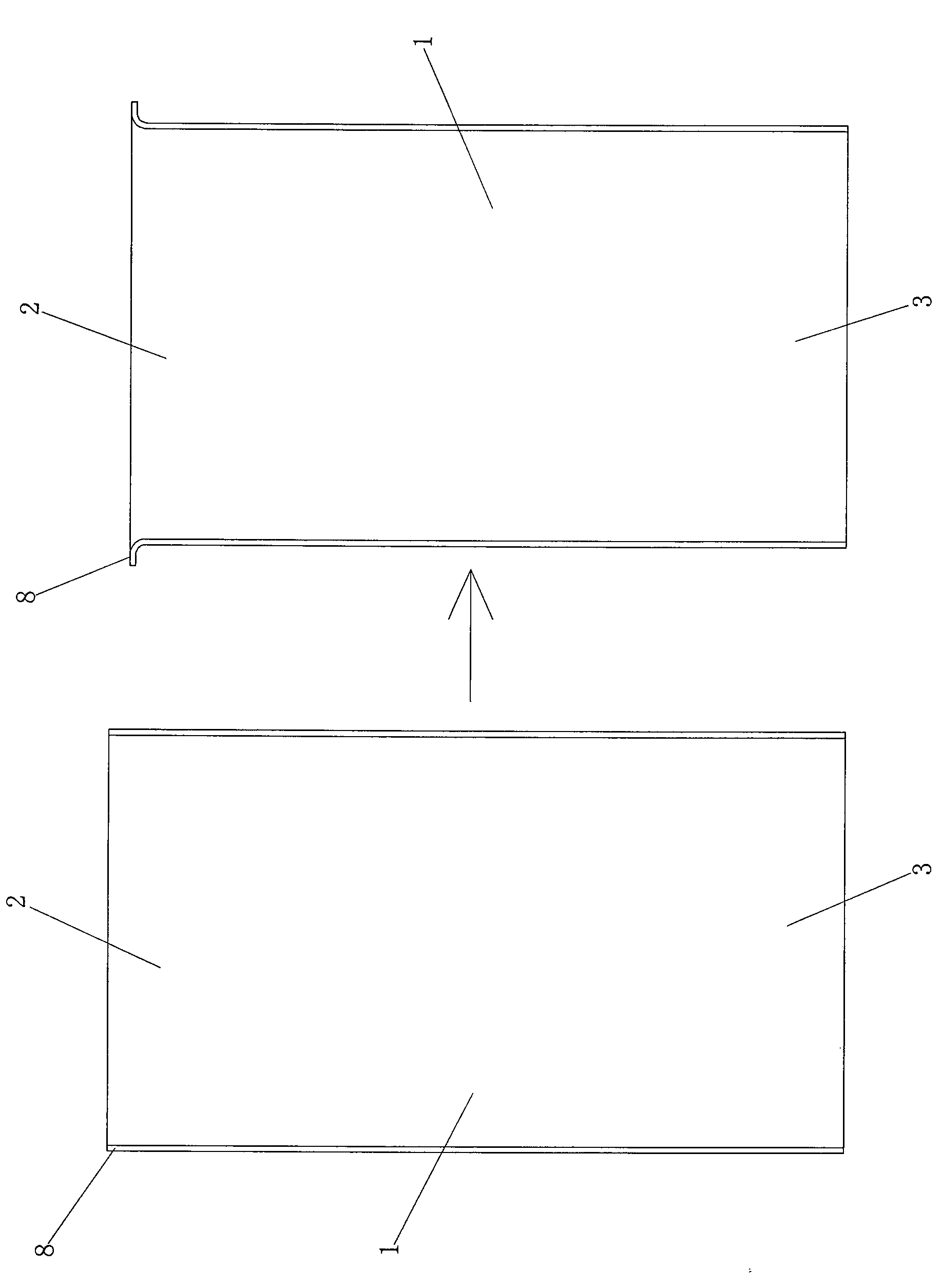

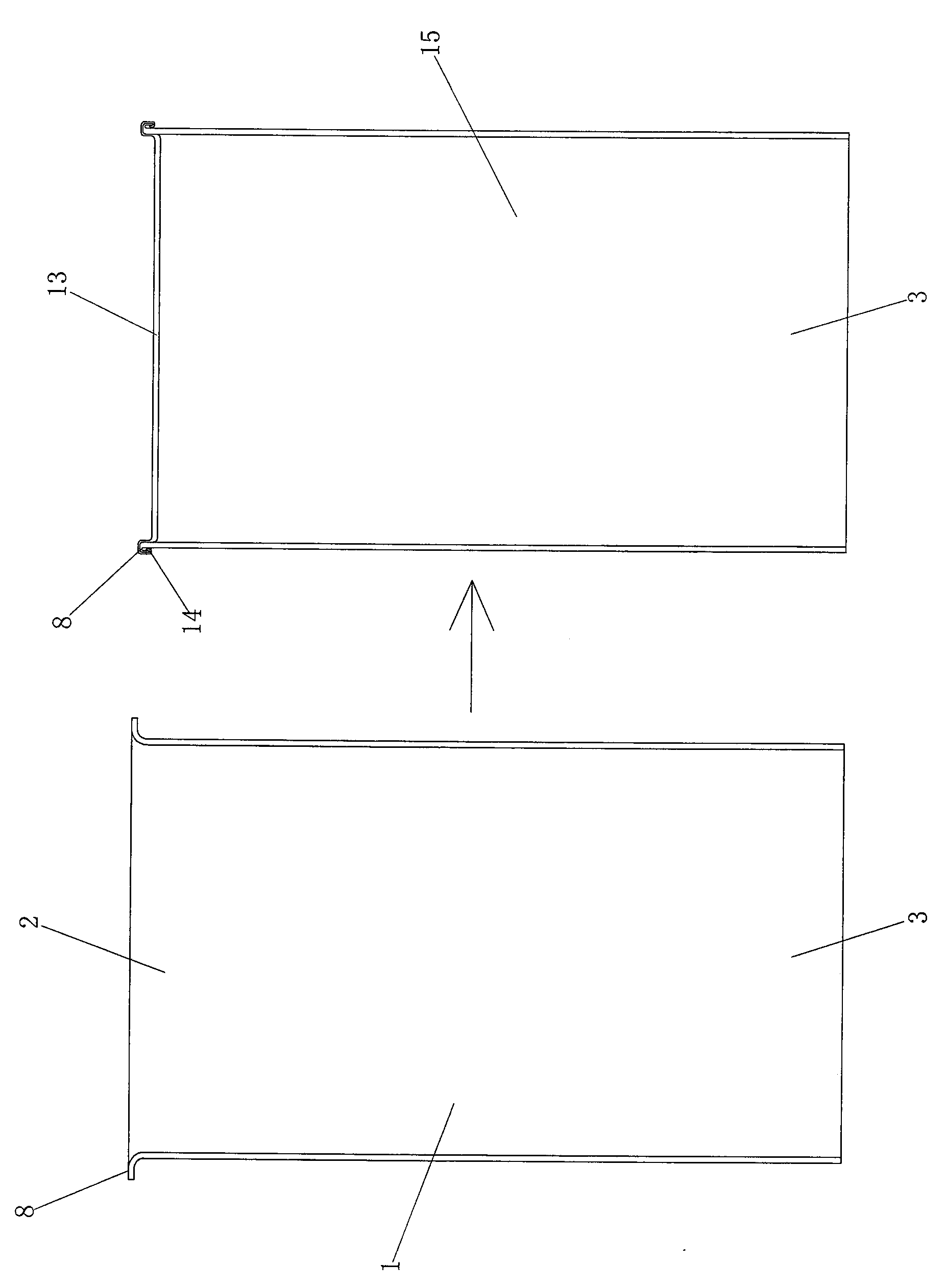

[0032] refer to Figure 1 to Figure 7 , the full-automatic high-speed production method of the metal packaging can body is characterized in that: the cylindrical metal can body tubes 1 are sequentially sent into the fully automatic high-speed production equipment 4 with the bottom mouth 2 facing upward and the top mouth 3 facing downward. The conveying mechanism 5 carries out gradual conveying, which is completed by the multi-station automatic production of the fully automatic high-speed production equipment 4, and the production process is carried out sequentially by the following steps:

[0033] ① When the metal can body 1 is transported to the first station 6 of the fully automatic high-speed production equipment 4, the first station lifting mechanism 7 at the lower part of the first station 6 lifts the metal can body 1 to make the metal can body The mouth edge 8 of the bottom mouth 2 of 1 cooperates with the first station rolling flanging mechanism 9 on the upper part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com