Color model printing system with double workbenches

A color model and printing system technology, applied in the field of double-worktable color model printing system, can solve the problems of tediousness and complexity, single workpiece body, single color, etc., achieve the effect of large working space, improving work efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

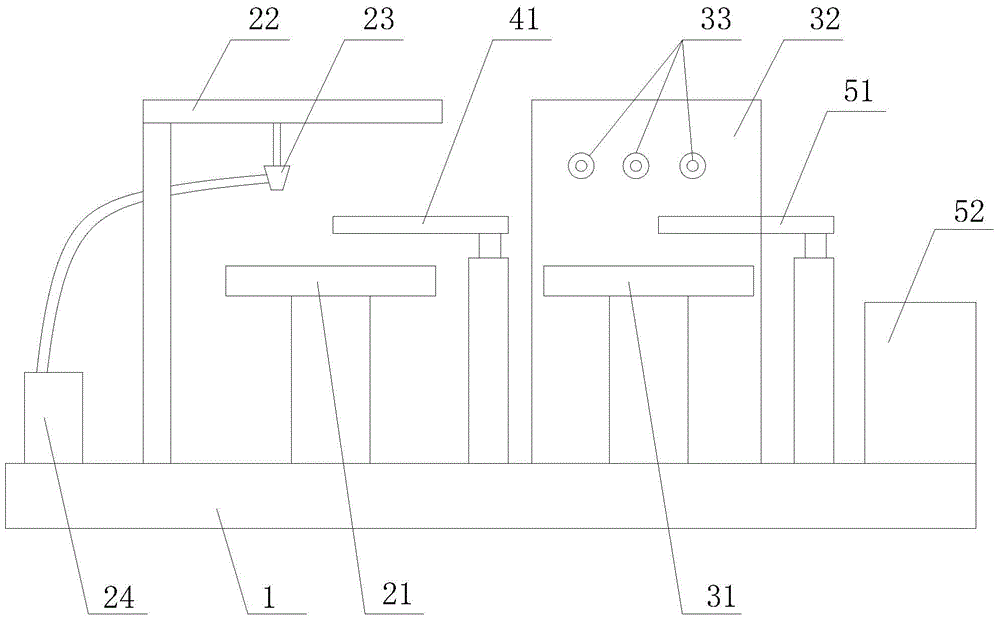

[0015] like figure 1 As shown, a double-table color model printing system proposed by the present invention includes: a base 1, a model printing module, a coloring module, a transition module, a blanking module and a control module.

[0016] The model printing module includes: a first workbench 21 , a first spray head support 22 , a base material spray head 23 and a base material box 24 . The first workbench 21 and the first spray head support 22 are installed on the base 1, the base material spray head 23 is movably installed on the first spray head support 22 and is positioned above the first workbench 21, the base material box 24 is connected to the base material spray head 23 Supply it with printing base material. The model printing module is used to complete the work of printing the workpiece model with the base material.

[0017] The coloring module includes: a second workbench 31 , a second nozzle holder 32 , N color nozzles 33 and N color material boxes (not shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com