Adjustable sensor installation platform

A technology for installing platforms and sensors, which is applied to the transmission device of synchronous propulsion components, supporting machines, water-action propulsion components, etc., can solve the problems of distance reduction, heavy installation workload, and influence on measurement accuracy, so as to achieve convenient installation, Precisely adjust the installation position and angle, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

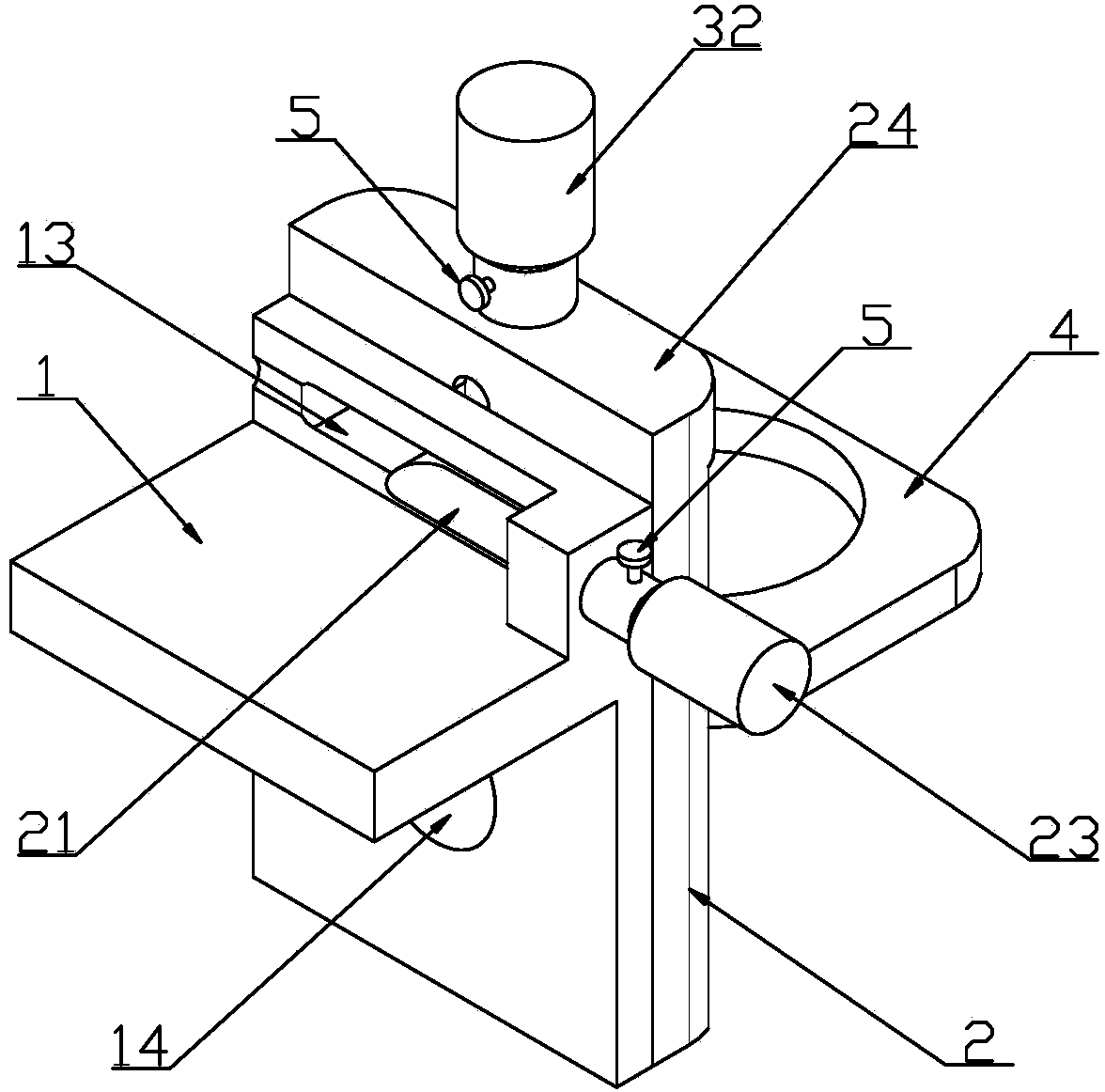

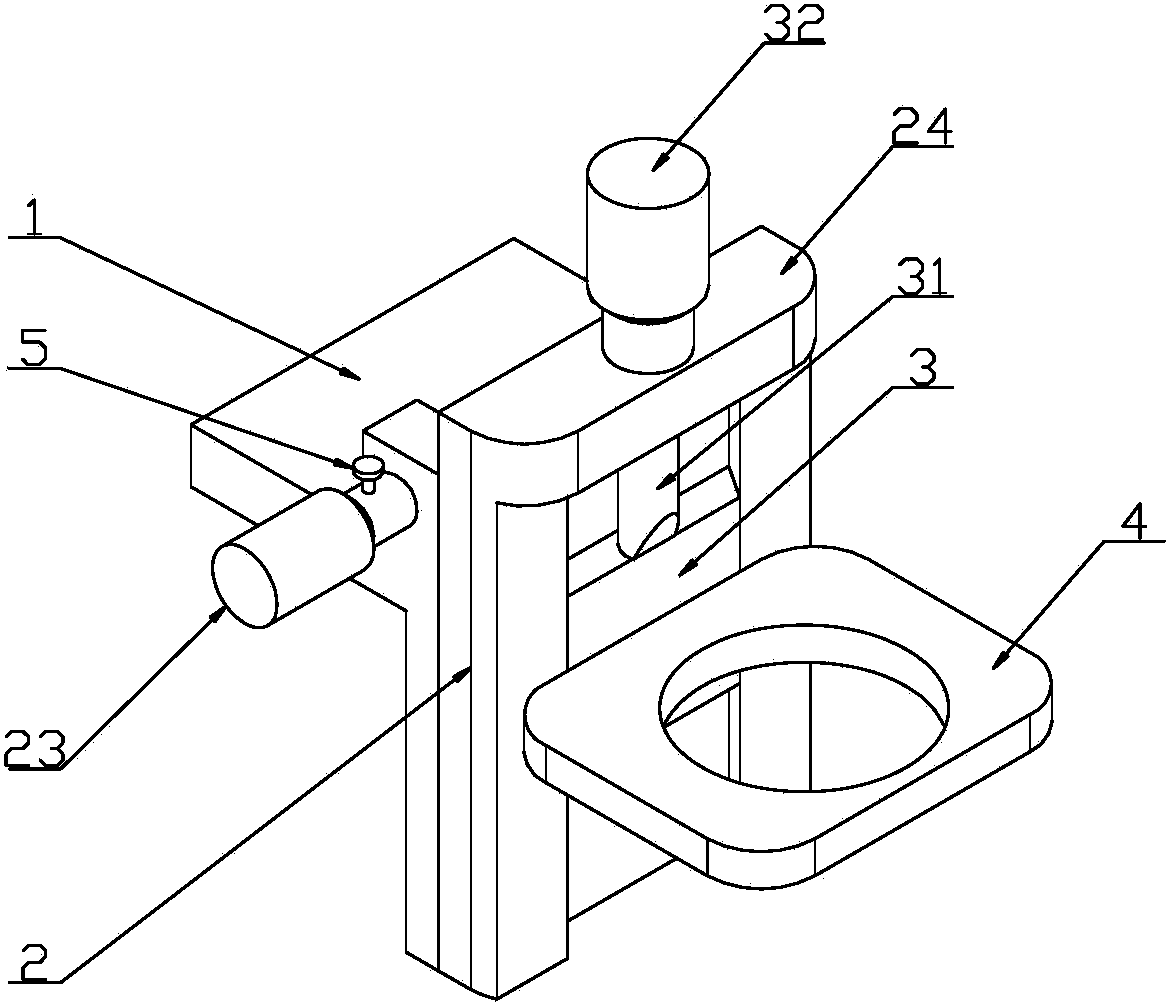

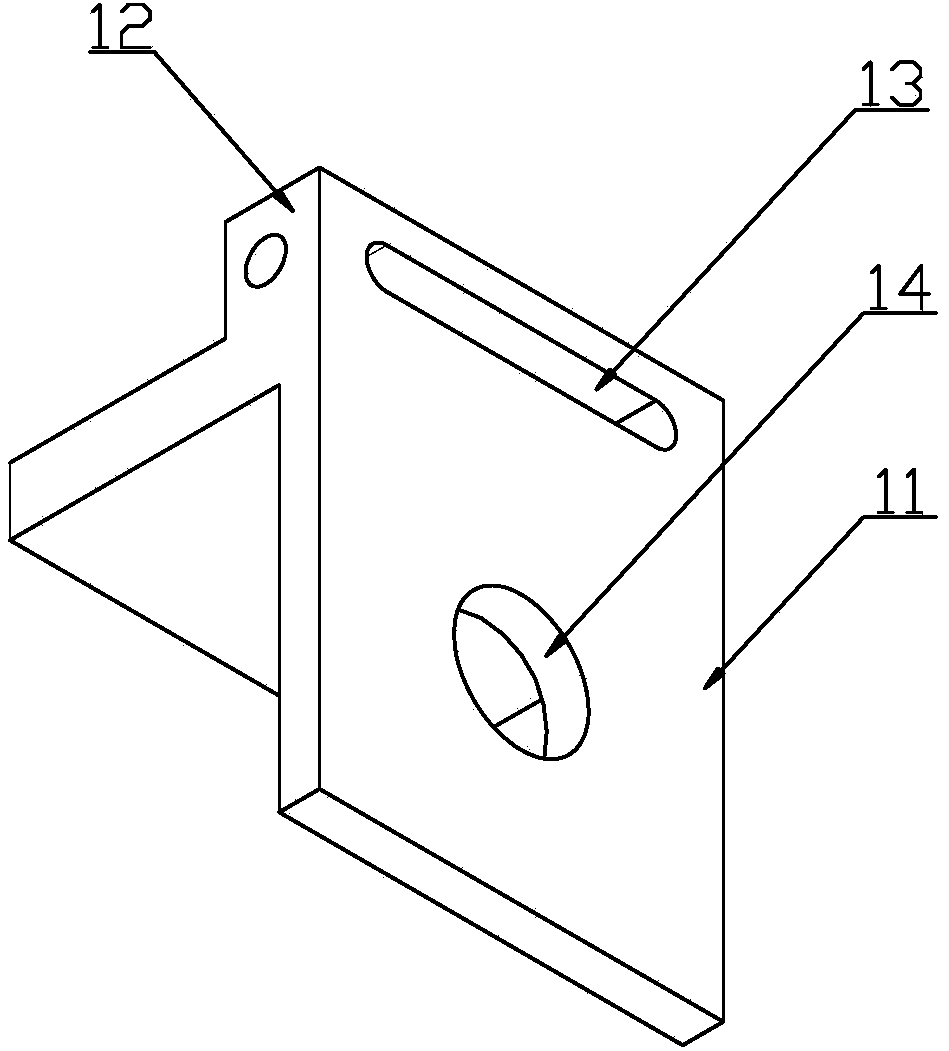

[0019] Such as Figure 1~6 As shown, the improved adjustable sensor mounting platform of the present invention includes a fixed base 1, a rotating platform 2, a sliding platform 3, a fixed sensor platform 4, a rotating platform push-pull rod 21, a sliding platform push-pull rod 31, a first differential head 23, a second Two differential head 32. The fixed base 1 includes a vertical panel 11 of the fixed base and a side panel 12 of the fixed base. The vertical panel 11 of the fixed base is provided with a horizontal sliding groove 13 passing through the vertical panel 11 of the fixed base. Rotating platform 2 back sides are provided with vertical sliding groove 22, and rotating platform push-pull bar 21 is L-shaped (as Figure 4 As shown), it is used to drive the rotating platform 2 to rotate, its long side is integrally installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com