Three-line tower crane

A three-wire, tower crane technology, applied in the direction of towers, cranes, clockwork mechanisms, etc., can solve the problems of poor impact resistance, frequent information exchange, difficult construction, etc., to achieve strong impact resistance, easy transfer and transportation, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

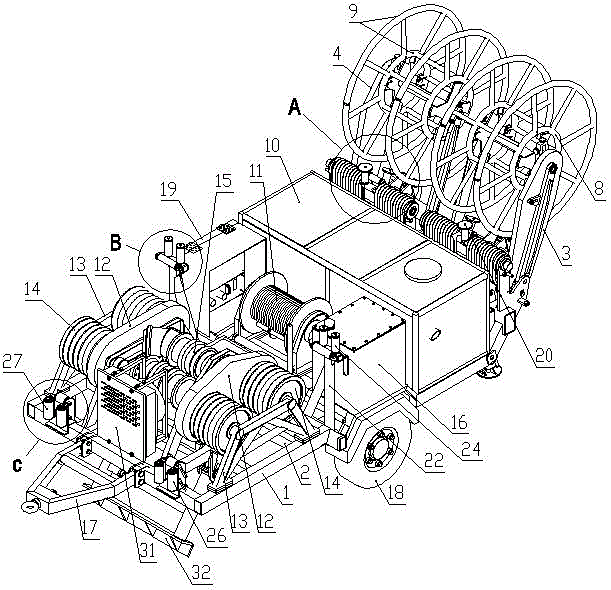

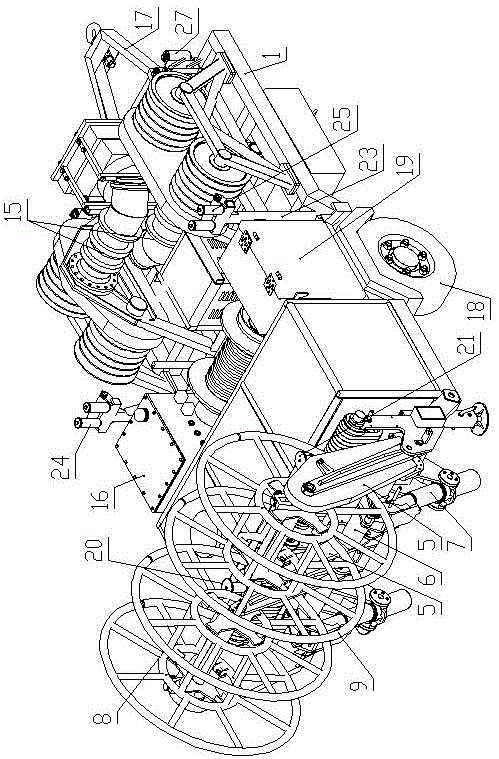

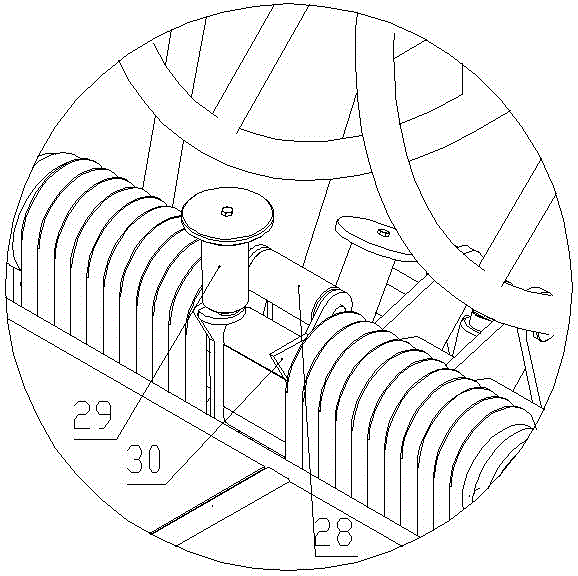

[0056] Such as Figure 1 to Figure 5 As shown, the three-wire tower crane of the present invention includes an underframe, and the underframe is composed of an underframe longitudinal beam 1 and an underframe crossbeam 2 that are fixedly connected together.

[0057] The rear end of the chassis is hinged with a left tailstock 3 and a right tailstock 4; the left tailstock 3 and the right tailstock 4 are symmetrically arranged side by side and both have the same structure, and both include a pair of support arms 5 hinged at the rear end of the chassis, connecting The tailstock crossbeam 6 between the two support arms 5 and the adjustment oil cylinder 7 hinged at the bottom frame rear end, the extension rod of the adjustment oil cylinder 7 is hinged upwardly with the tailstock crossbeam 6;

[0058] The left tailstock 3 and the right tailstock 4 are respectively equipped with a left rope reel 8 and a right rope reel 9 for winding and carrying steel wire ropes, the left rope reel 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com