Preparation method of glass mosaic with wood flower stone

A glass mosaic and wood flower stone technology is applied in the field of building materials, which can solve the problems of damage, poor stability, and lack of vividness, and achieve the effect of beautiful decoration and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to understand the invention more easily, the practical implementation of the invention will be specifically described below with specific examples.

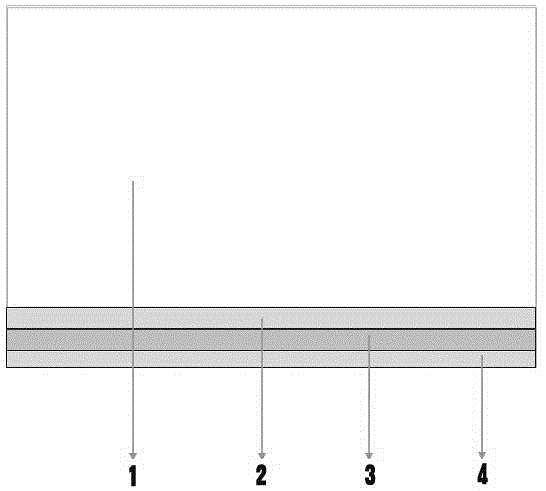

[0010] as follows figure 1 As shown, the preparation method of the wood flower stone glass mosaic of the present invention is: the described glaze surface layer 2 is poured with water after cleaning the glass body 1, and the water on the surface of the glass body 1 has no fluidity when water is poured, and then glazed , so that the glaze and water are fused, and then atomized and sprayed with water to refine the fusion edge of the water glaze, so that the texture is more natural after the texture is naturally melted and dispersed by water.

[0011] The pearl powder layer 3 and the water glaze layer 2 are baked and dried at about 100 degrees, and then the pearl powder layer 3 is printed on the water glaze layer 2, so that the glass mosaic has a pearl effect.

[0012] After the white sealing layer 4 and the pearl p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com