Fetching device of aging pond for powder of hollow building blocks made of shale

A technology of hollow block and reclaiming device, which is applied in auxiliary molding equipment, ceramic molding machines, mechanically driven excavators/dredgers, etc., can solve the problems of inconvenient movement, improve the aging effect, and ensure first-in-first-out Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

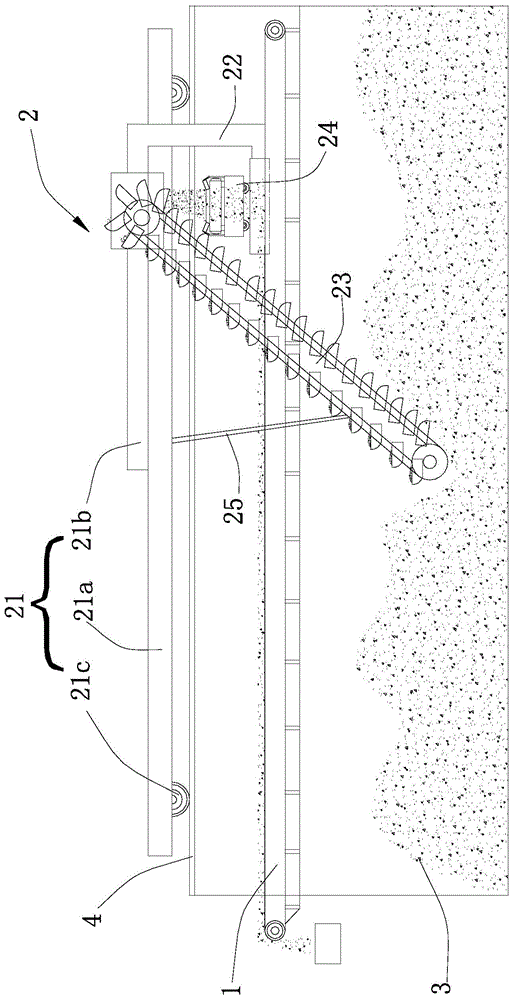

[0013] Such as figure 1 The shown shale hollow block powder material aging tank reclaiming device includes a discharge belt conveyor 1 and a bridge-type multi-bucket excavator 2, wherein the discharge belt conveyor 1 is arranged along the length direction of the aging tank 3 and is located in the aging tank 3 on one side, above both sides of the aging tank 3, there are guide rails 4 parallel to the discharge belt conveyor 1.

[0014] The bridge type multi-bucket excavator 2 includes a frame body 21, a walking trolley 22, a boom 23 and an intermediate belt conveyor 24, and the frame body 21 is divided into sliding beam frames 21a on both sides and sliding beam frames fixed on the two sides The fixed beam frame 21b between the frames 21a, the sliding beam frame 21a is arranged along the length direction of the aging tank, the lower part of the sliding be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com