A kind of ripening process of ultra-coarse denier viscose filament

A viscose filament, ultra-coarse denier technology, applied in the filament forming process, viscose-made man-made filament, starting to become filament, etc. There are many problems, such as low cost, less mixing, and less milky phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

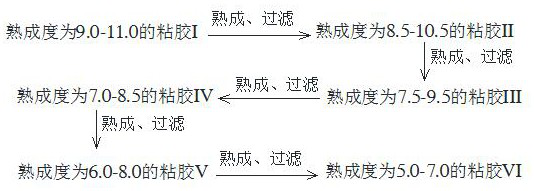

[0043] refer to figure 1 , an ultra-coarse denier viscose filament aging process, belonging to the technical field of viscose filament spinning technology, the specific steps are as follows:

[0044] a. get ready the viscose glue I that required maturing degree in the viscose filament ripening process of ultra-coarse denier is 9-11, stand-by;

[0045] b. Continue aging and filtering the viscose I obtained in step a to obtain viscose II with a maturity of 8.5-10.5;

[0046] c. Continue aging and filtering the viscose II obtained in step b to obtain viscose III with a maturity of 7.5-9.5;

[0047] d. Continue aging and filtering the viscose III obtained in step c to obtain viscose IV with a maturity of 7.0-8.5;

[0048] e. Continue aging and filtering the viscose IV obtained in step d to obtain viscose V with a maturity of 6.0-8.0;

[0049] f. Continue aging and filtering the viscose V obtained in step e to obtain viscose VI with a maturity of 5.0-7.0, and send it to the next...

Embodiment 2

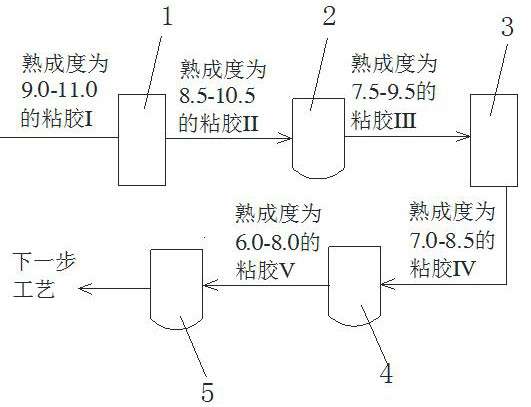

[0052] refer to figure 2 , an ultra-coarse denier viscose filament aging process, belonging to the technical field of viscose filament spinning technology, the specific steps are as follows:

[0053] a. get ready the viscose glue I that the degree of maturation required in the supercoarse denier viscose filament ripening process is 9-11, stand-by;

[0054]b. The viscose I obtained in step a is transported to the filter I1 to filter and continue to mature so that the degree of maturity is reduced to 8.5-10.5 to obtain viscose II;

[0055] c. transport the viscose II in step b to the buffer barrel I2, buffer and continue to mature the viscose, so that the degree of maturity reaches 7.5-9.5, and obtain the viscose III;

[0056] d. Conveying the viscose III in step c to the filter II3, so that the viscose III continues to mature in the filter II3, and the degree of maturity is reduced to 7.0-8.5 to obtain the viscose IV;

[0057] e. transport the viscose IV in step d to the buf...

Embodiment approach

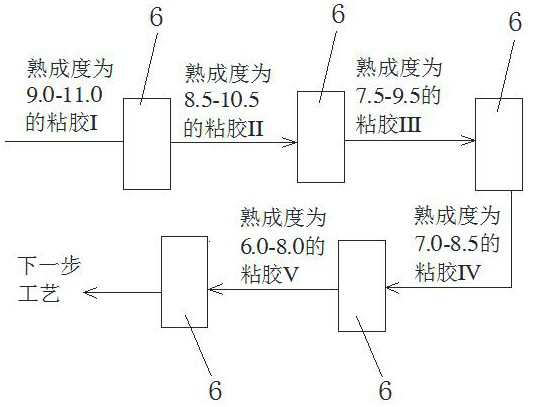

[0070] refer to image 3 , an ultra-coarse denier viscose filament maturation process, belonging to the technical field of viscose filament spinning technology, is another preferred embodiment, and the specific steps are as follows:

[0071] a. get ready the viscose glue I that required maturing degree in the viscose filament ripening process of ultra-coarse denier is 9-11, stand-by;

[0072] b. continue to ripen the viscose I obtained in step a through a pipeline, and filter through a pipeline filter 6 to obtain viscose II with a degree of maturity of 8.5-10.5;

[0073] c. continue to mature the viscose II obtained in step b through the pipeline, and filter through the pipeline filter 6 to obtain the viscose III with a maturity of 7.5-9.5;

[0074] d. continue to ripen the viscose III obtained in step c through a pipeline, and filter through a pipeline filter 6 to obtain viscose IV with a maturity of 7.0-8.5;

[0075] e. continue to mature the viscose IV obtained in step d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com