A continuous vacuum drying reaction device and system

A technology of vacuum drying and reaction equipment, which is applied in the direction of dry gas arrangement, dry solid material, dry cargo handling, etc. It can solve the problems of inability to realize automatic control, incomplete performance, difficult handling of materials containing water, etc., and achieve continuous and stable production operation , promote recycling, remove the effect of thorough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

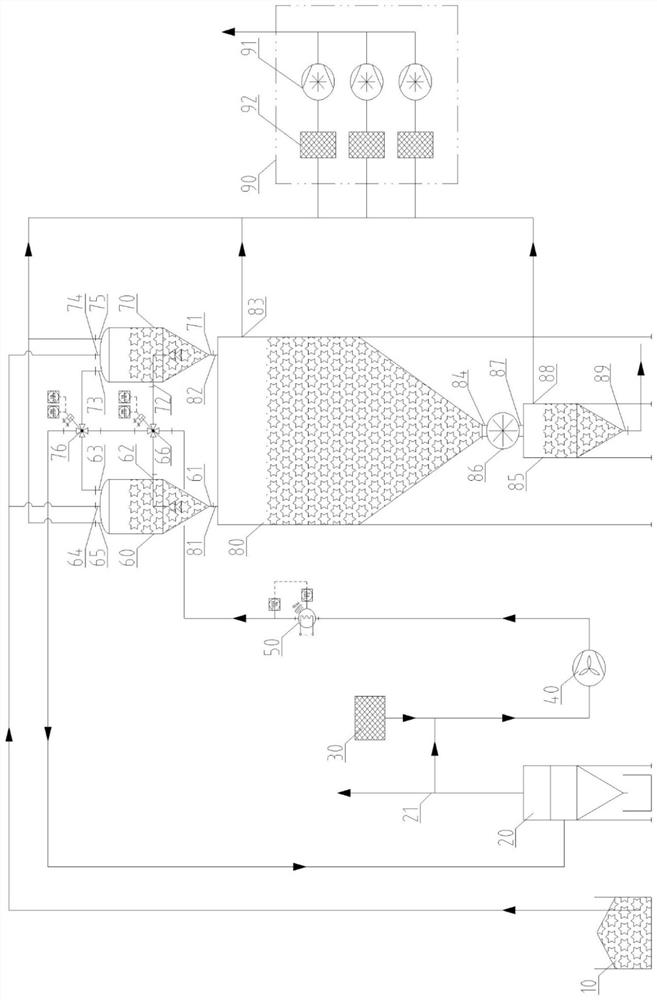

[0018] Example: such as figure 1 Shown, a kind of continuous vacuum drying reaction device and system, it comprises negative pressure hopper 10, bag filter 20, air filter 30, blower 40, heater 50, drier A 60 and drier B 70, vacuum Reactor 80, buffer silo 85, vacuum pump group 90 and PLC controller, wherein the bottom of dryer A is provided with dryer A outlet 61, and the bottom side of dryer A is provided with dryer A inlet 62 , the top of dryer A is provided with dryer A air outlet 63, dryer A inlet 64, dryer A exhaust outlet 65, the bottom of dryer B is provided with dryer B outlet 71, and the dryer B The side edge of the bottom is provided with a dryer B air inlet 72, and the top of the dryer B is respectively provided with a dryer B air outlet 73, a dryer B feed port 74, and a dryer B air outlet 75,

[0019] The air inlet 62 of the dryer A and the air inlet 72 of the dryer B are respectively arranged on the ports on the left and right sides of the four-way cock valve A 66...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com