A Cooling and Heating Alternating System for Improving Coal Seam Gas Drainage

A technology of alternating cold and heat, coal seam gas, applied in the direction of gas discharge, mining fluid, mining equipment, etc., can solve the problems of failure of coal seam storage body rupture, unsatisfactory application effect, difficult to form long cracks, etc., to shorten the preparation time Time, the time used is optimized, and the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

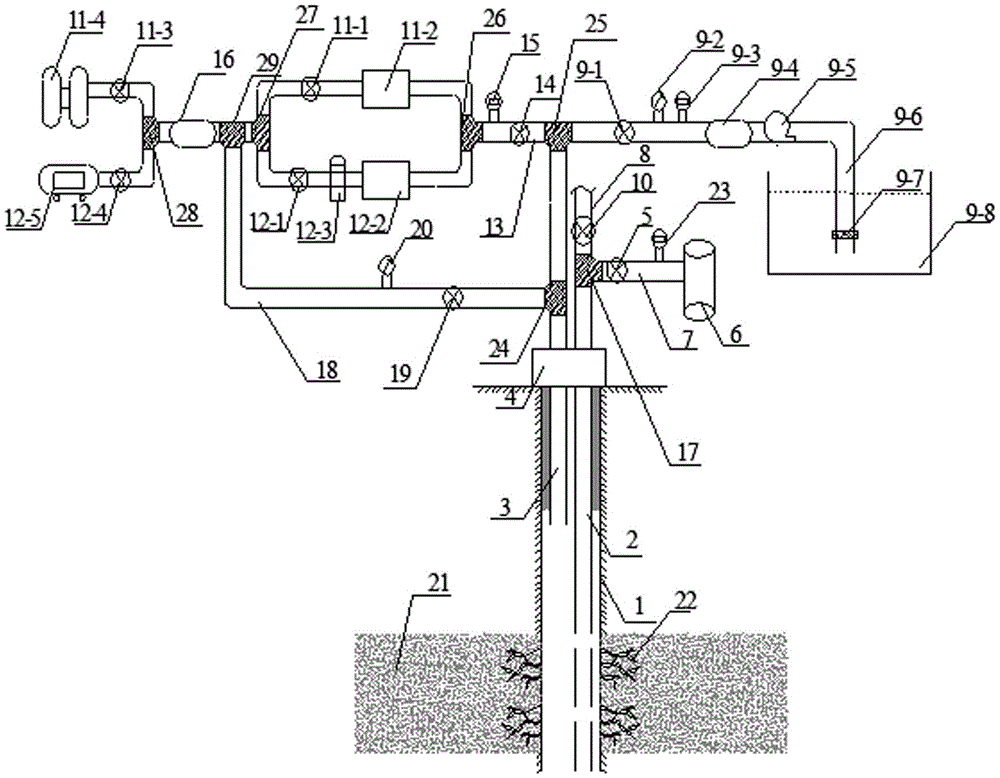

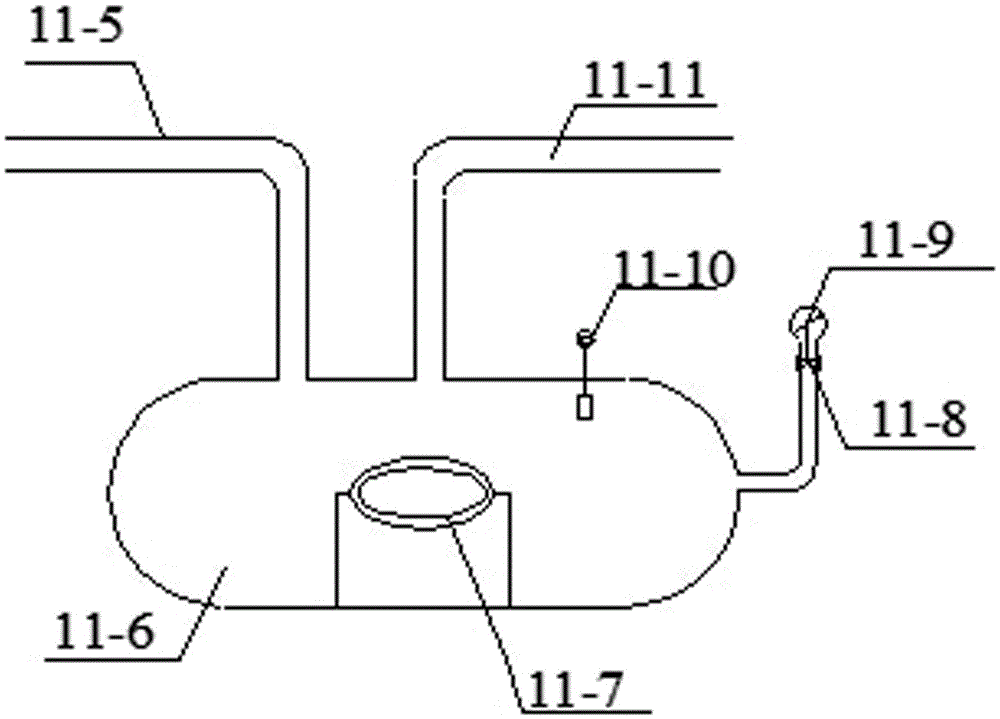

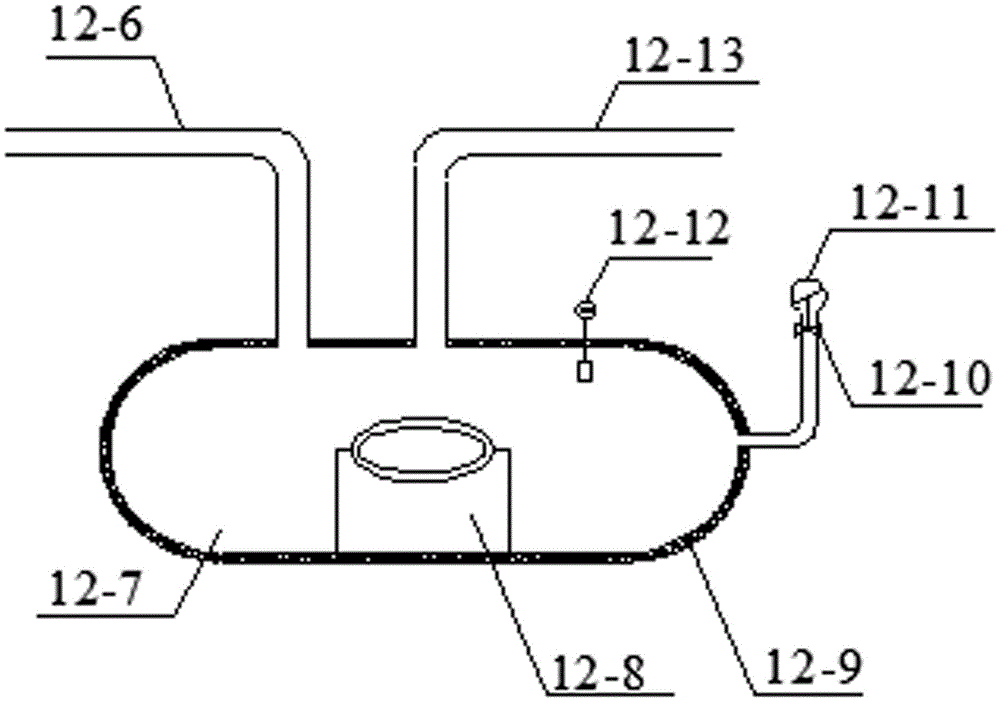

[0026] A cooling and heating alternating system for improving the gas extraction rate of coal seams. The injection pipe 3 and the gas extraction pipe I2 sent to the surface drilling 1 enter the ground through the sealing device 4; the outer end of the gas extraction pipe I2 passes through the first tee 17 The drainage pipe 8 and the gas drainage pipe II7 are respectively connected, the other end of the gas drainage pipe II7 is connected with the drainage pump 6, a valve I10 is provided between the first tee 17 and the drainage pipe 8, and the gas drainage pipe II7 is A valve II5 and a flow meter III23 are provided; the ground end of the injection pipe 3 is separated from the gas injection pipe I18 and the extension end through the second tee 24; Water pipe 9-6, the initial end of water injection pipe 9-6 is placed in the water tank 9-8 that water is housed, and the part of water injection pipe 9-6 that is located in the water is provided with filtering device 9-7, and water inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com