Speed changing box of motor-driven gear shifting mechanism

A shifting mechanism and motor-driven technology, which is applied in the field of gearboxes, can solve the problems of unstable shifting force and inaccurate shifting, and achieve the effect of accurate shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

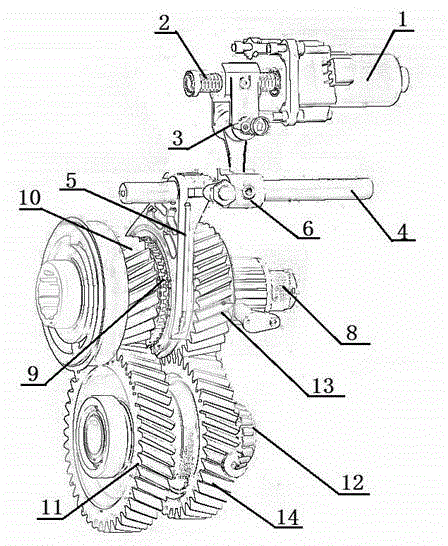

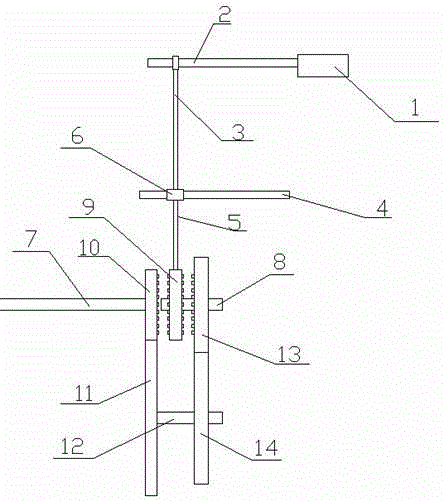

[0013] Such as figure 1 , 2 As shown, the gearbox of the motor-driven shift mechanism of the present invention includes a shift motor 1, a roller screw 2, a shift head 3, a fork shaft 4, a shift fork 5, a guide block 6, an input shaft 7, output shaft 8. The ball screw 2 is connected to the output shaft of the shift motor 1, and the upper end of the dial 3 is provided with an internal thread sleeve, and the internal thread sleeve is threadedly connected with the roller screw 2; The lower end of the toggle 3 fixes the shift fork 5 . The actuator includes an input shaft 7, an output shaft 8, a needle bearing 9, a first gear 10, a second gear 11, a shaft 12, a third gear 13, and a fourth gear 14. The input shaft 7 and the first gear 10 is fixedly connected, the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com