Heat dissipation system for stage lamps and stage lamps using the system and its heat dissipation method

A technology for cooling systems and lamps, applied in lighting applications, installations for theaters and circuses, lighting and heating equipment, etc. Large convection area and heat dissipation area, large heat transfer coefficient of the whole system, and the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

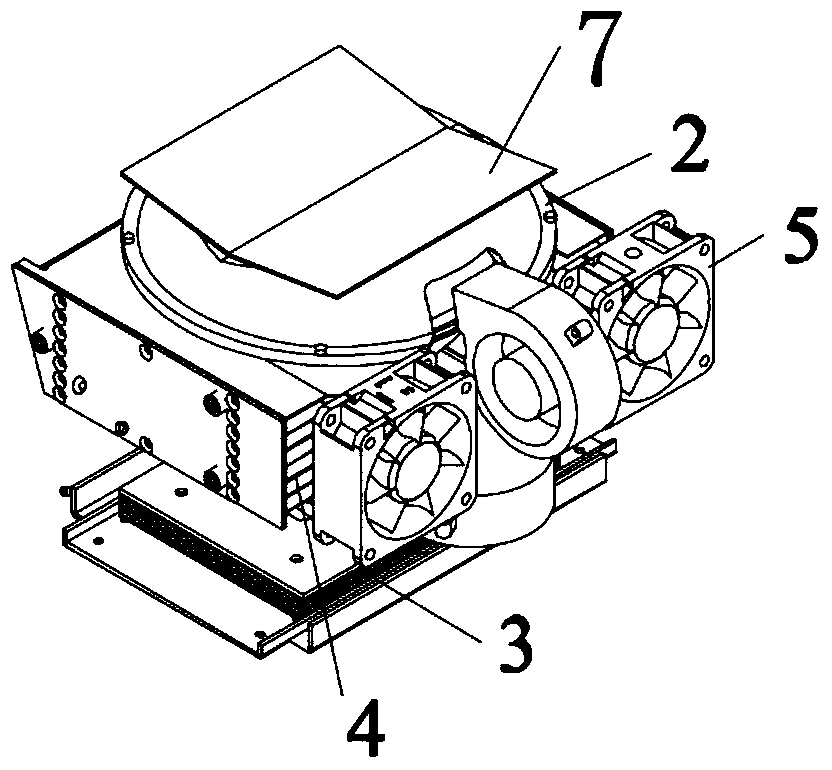

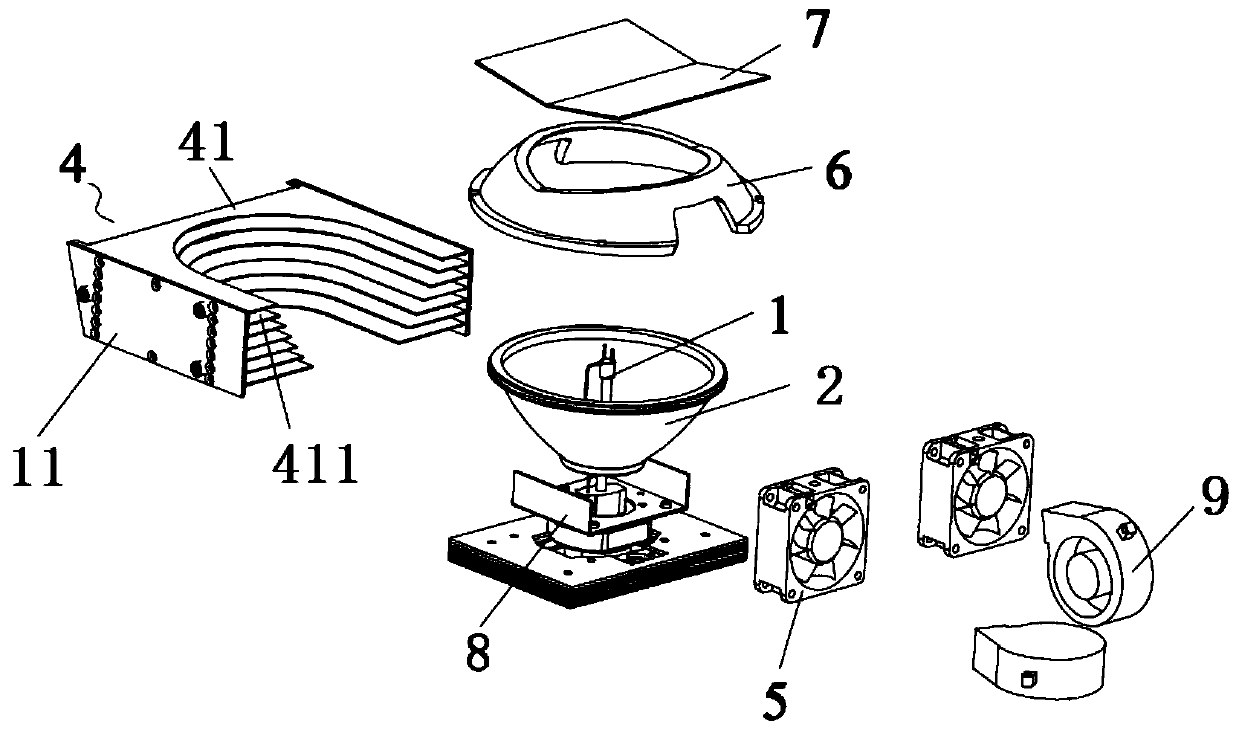

[0047] Such as Figures 1 to 6 Shown is the first embodiment of the heat dissipation system of the stage lamp of the present invention and the stage lamp and its heat dissipation method using the system, as figure 1 As shown, the heat dissipation system for stage lamps includes a light source 1, a first reflective assembly 2 surrounding the light source 1, and a fixing seat 3 for fixing the light source 1. The first reflective assembly 2 is a bowl-shaped structure or other structures; the heat dissipation system also It includes a heat dissipation component 4 surrounding the outer circumference of the first reflective component 2, the heat dissipation component 4 matches the shape of the first reflective component 2, preferably the heat dissipation component 4 is bonded to the first reflective component 2, of course, the heat dissipation component 4 can also be It is not attached to the first reflective component 2; the heat dissipation component 4 is formed by stacking a plur...

Embodiment 2

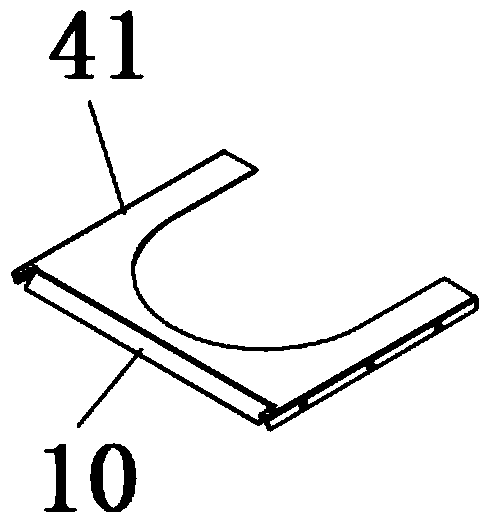

[0065] Such as Figure 7 to Figure 9 As shown, this embodiment is similar to Embodiment 1, except that the opening direction of the air duct 411 is inclined to the first reflective assembly 2 , and each air duct 411 is inclined to the central axis of the first reflective assembly 2 .

[0066] In this case, preferably, each air duct 411 is arranged tangentially along the outer circumferential surface of the first reflective assembly 2; in this way, on the one hand, the convection area between the air ducts 411 can achieve a larger convection area, which increases the heat dissipation area and has a large heat exchange area, which can effectively discharge the heat generated by the light source 1 in time and play a good heat dissipation effect; The outer peripheral surface of the first reflective component 2 is closer to adhering, which can effectively absorb infrared light, so that the infrared light can be transmitted as little as possible, so as to prevent other components of...

Embodiment 3

[0069] This embodiment is similar to the first embodiment, except that the heat dissipation assembly 4 is composed of two parts, that is, the heat dissipation fin 41 of the heat dissipation assembly 4 is composed of two halves of the heat dissipation fin units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com