Airflow sensor based on graphene nanowall and manufacturing method

A graphene nano wall and airflow sensor technology, applied in the field of airflow sensors, can solve the problems of high cost and large volume, and achieve the effects of low power consumption, good flexibility and excellent detection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

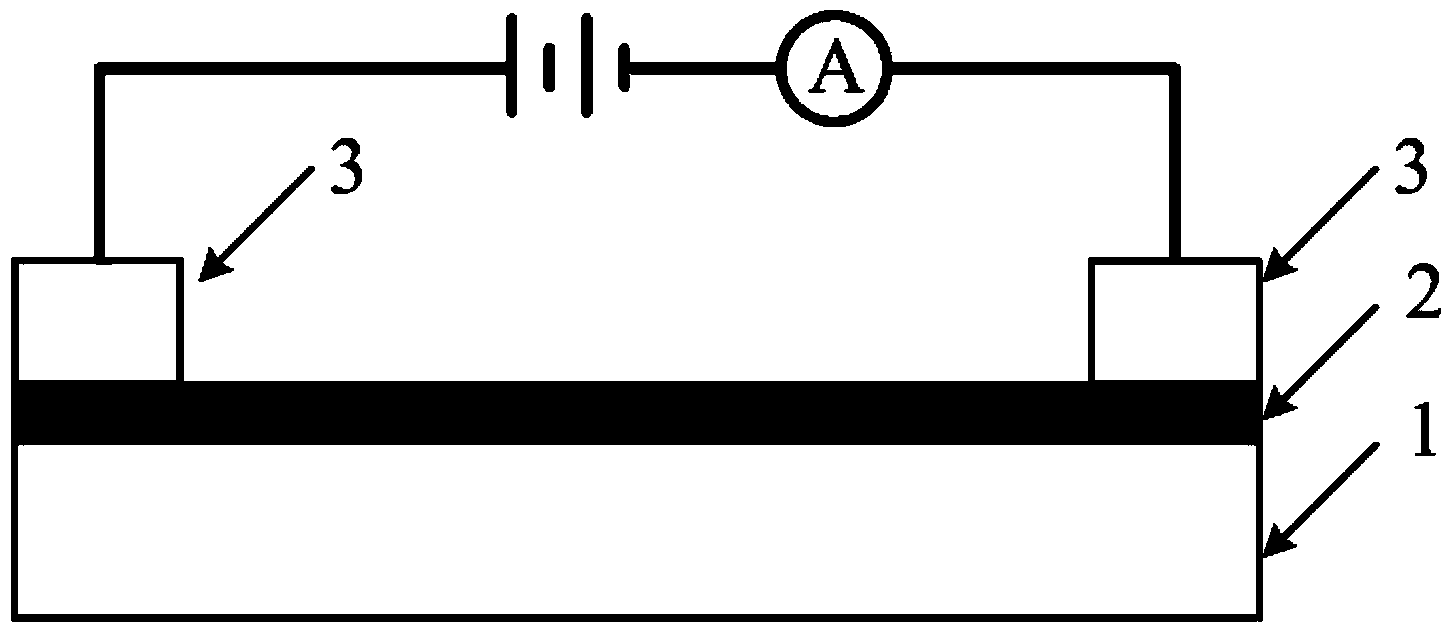

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

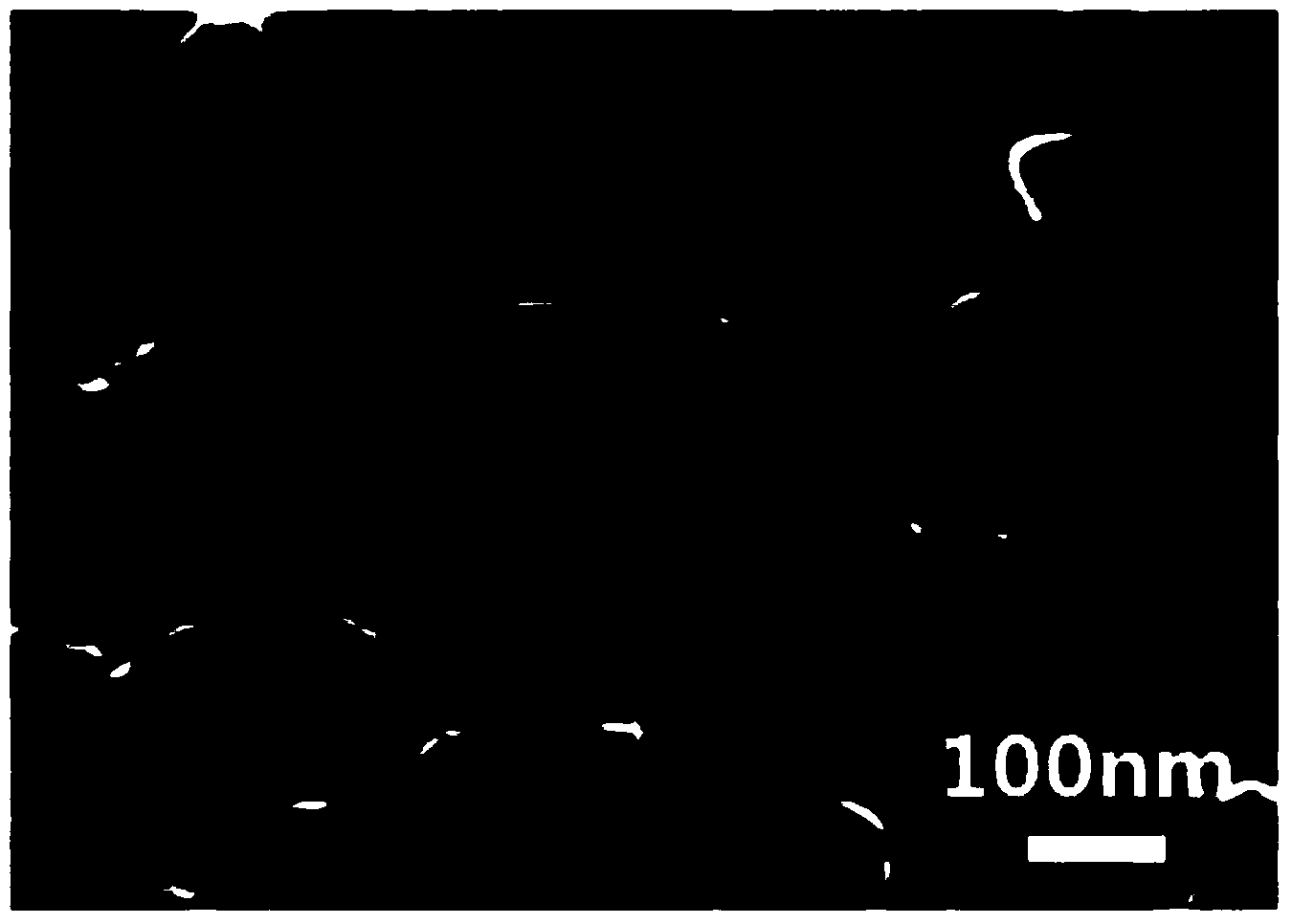

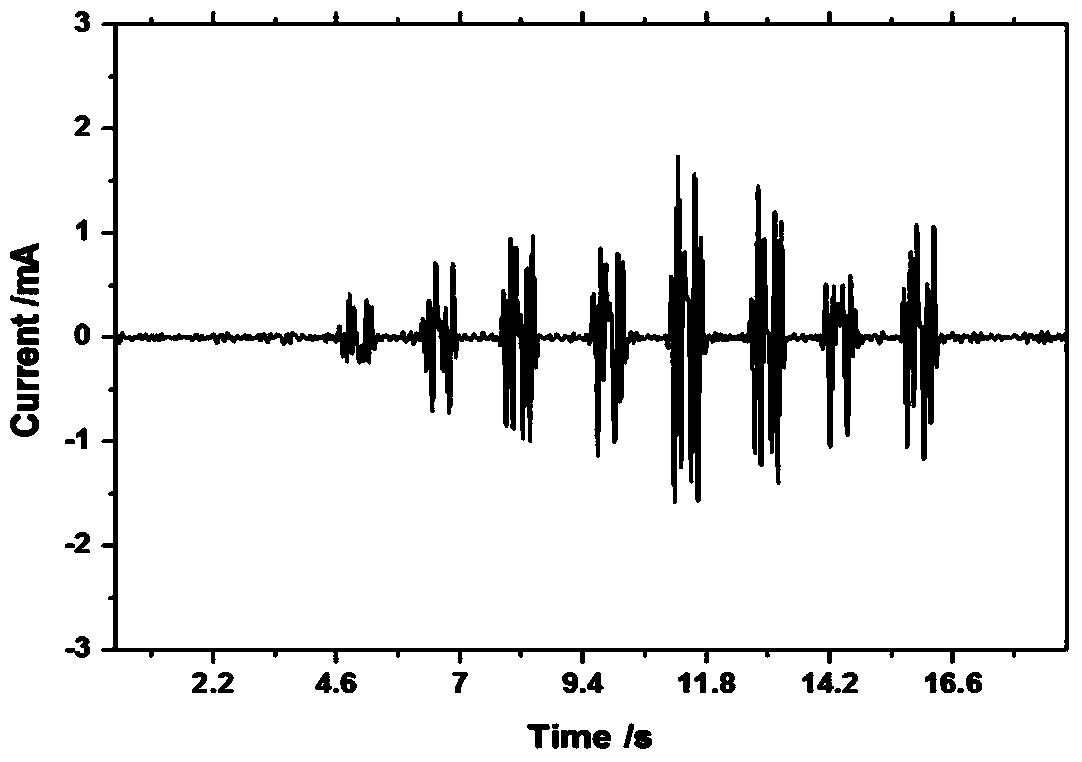

[0025] Graphene is a new type of two-dimensional crystal material, which is composed of a single layer of carbon atoms arranged in a honeycomb shape in a regular hexagonal shape. Due to the low-dimensional quantum properties of graphene and the chemical bonds formed by the unique sp2 hybridization, its free electron gas behavior is similar to that of massless Dirac fermions, so it exhibits very excellent mechanical, thermal, optical, and electrical properties. Graphene nanowalls are structured multilayer graphene, and the research found that the resistance of graphene nanowalls is very sensitive to the vibration of the substrate. The gas flow will cause a small vibration of the flexible substrate, which will cause the resistance of the sensitive layer of the grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com