On-line monitoring apparatus of ship mooring force and monitoring method thereof

A monitoring device, a technology for mooring force, applied in the direction of tension measurement, etc., can solve the problems of expensive purchase, troublesome installation, and inability to accurately measure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

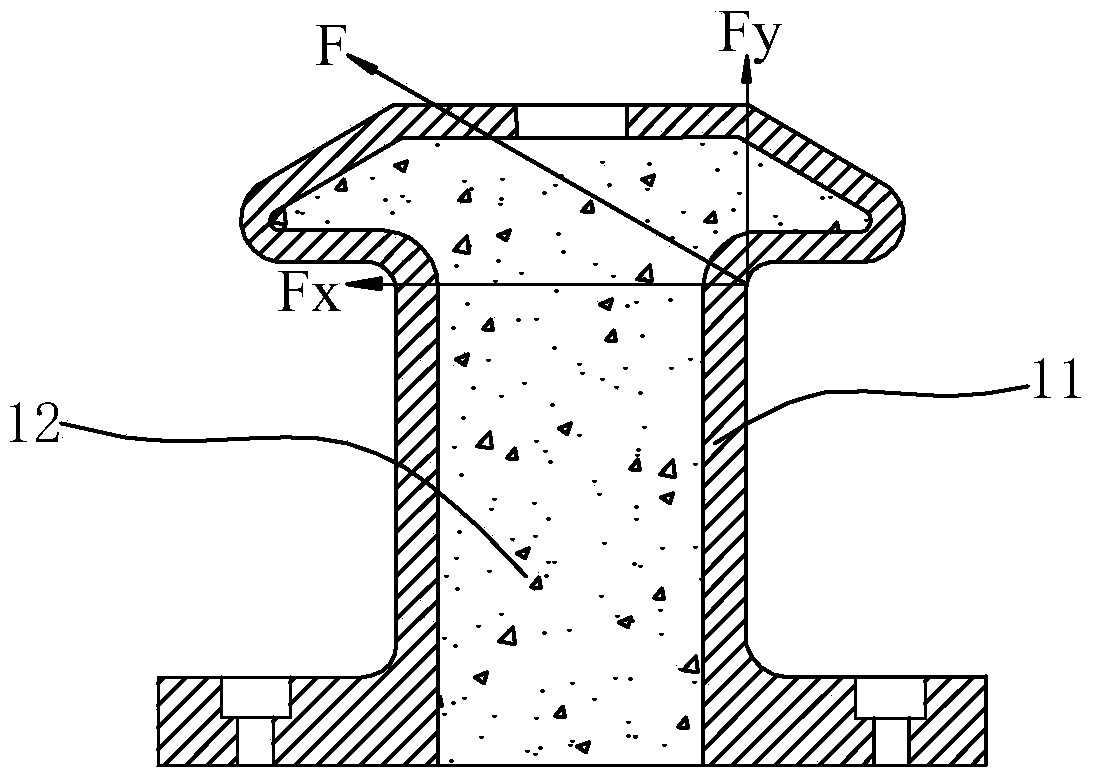

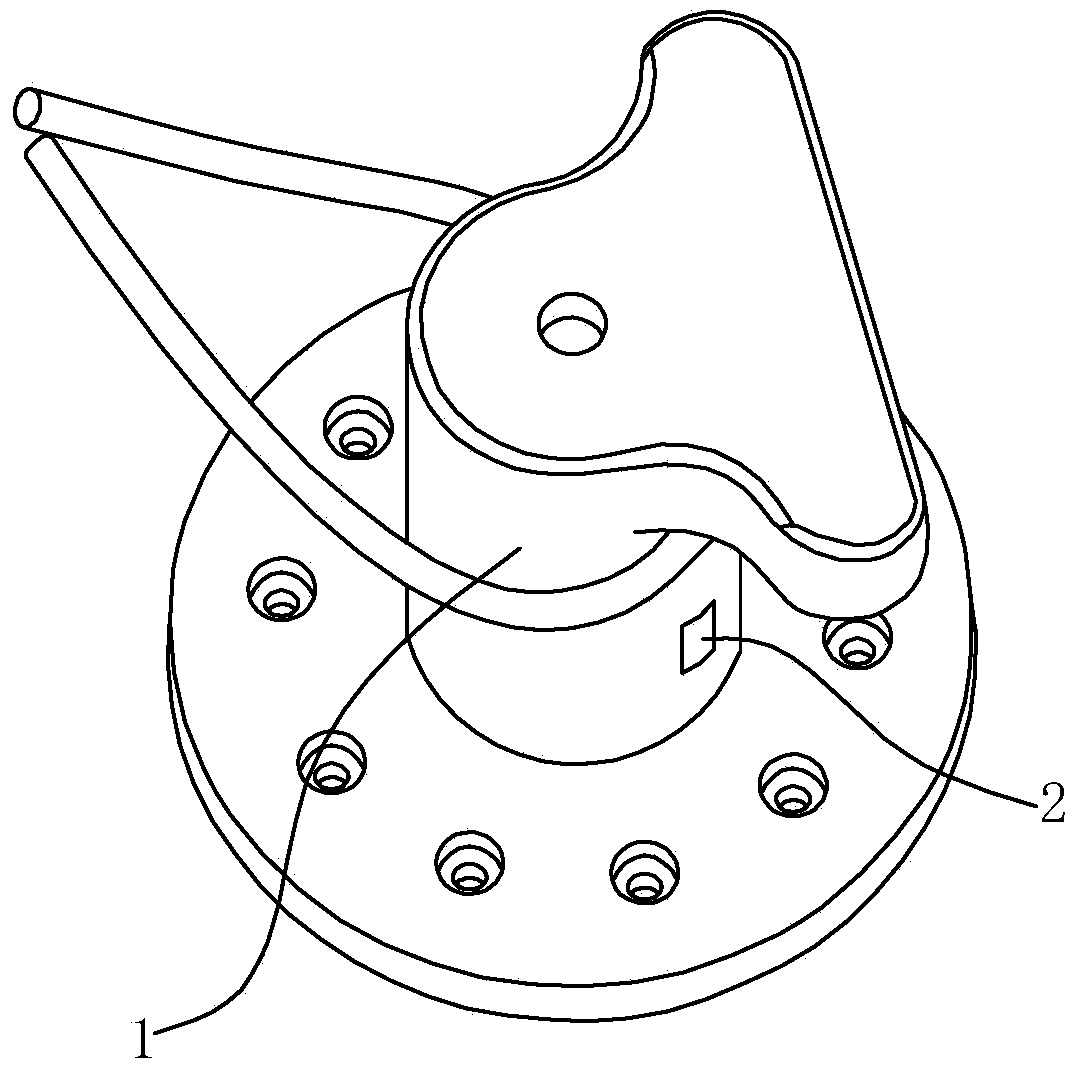

[0039] Such as Figure 1 to Figure 6 As shown, a kind of ship mooring force online monitoring device in the present embodiment includes the strain electric measuring device installed on the bollard 1, and the strain bridge signal conditioning connected with the strain electric measuring device device 3, a power supply connected to the strain bridge signal conditioner 3, a strain signal acquisition card 4, and a terminal processor connected to the strain signal acquisition card 4.

[0040] Wherein, the strain electric measuring device adopts a metal foil strain gauge 2 , and the metal foil strain gauge 2 is pasted and arranged on the column of the bollard 1 . Among them, the metal foil strain gauge 2 includes a base 21, a metal foil sensitive grid 22 arranged on the base 21, a protective sheet 23 covering the metal foil sensitive grid 22, and a signal output connector connected to the metal foil sensitive grid 22 .

[0041] The aforementioned strain bridge signal conditioner ...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 only lies in:

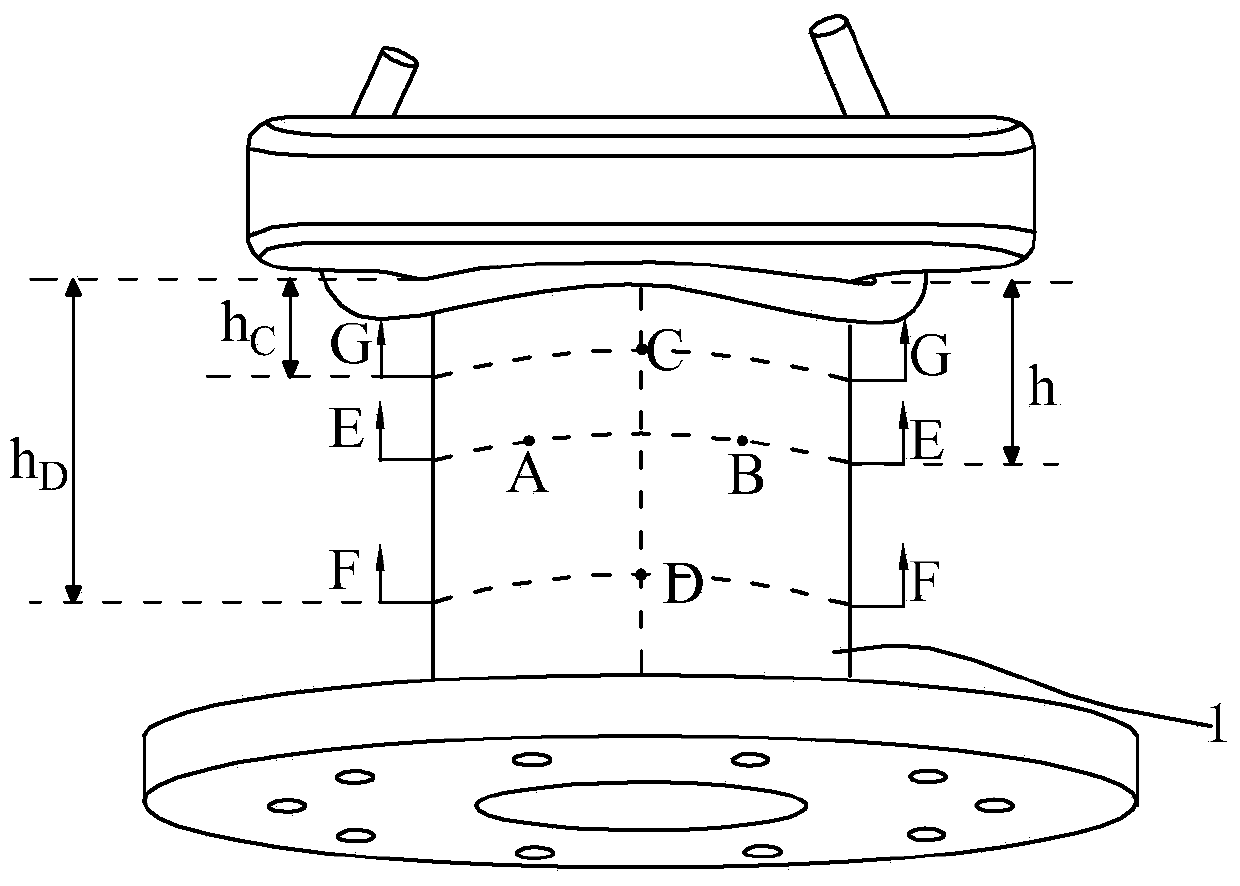

[0059] Such as Figure 7 As shown, the monitoring method of the ship's mooring force online monitoring device in the present embodiment includes the following steps:

[0060] Step 1. Select two stress monitoring points C and D on the cylindrical surface of the bollard 1 and on the same straight line parallel to the axis of the bollard 1, and fix the metal foil strain gauge 2 at the stress monitoring point C and D, wherein the base 21 of the metal foil strain gauge 2 is attached to the outer cylindrical surface of the bollard 1;

[0061] Before the metal foil strain gauge 2 is pasted, use a scraper or file to remove the oxide skin and dirt at the monitoring points C and D, and use fine sandpaper to polish a 3-5 times the area of the metal foil strain gauge 2 at the monitoring point. smooth surface. During the pasting process, use absorbent cotton balls dipped in anhydrous alcohol and other solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com