Combined type propeller thrust torque measurement device

A technology of torque measurement and propeller, applied in the field of combined propeller thrust torque measurement device, can solve the problems of difficult replacement, easy damage of tension and pressure sensor components, low vibration measurement accuracy of the propulsion system, etc., to achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

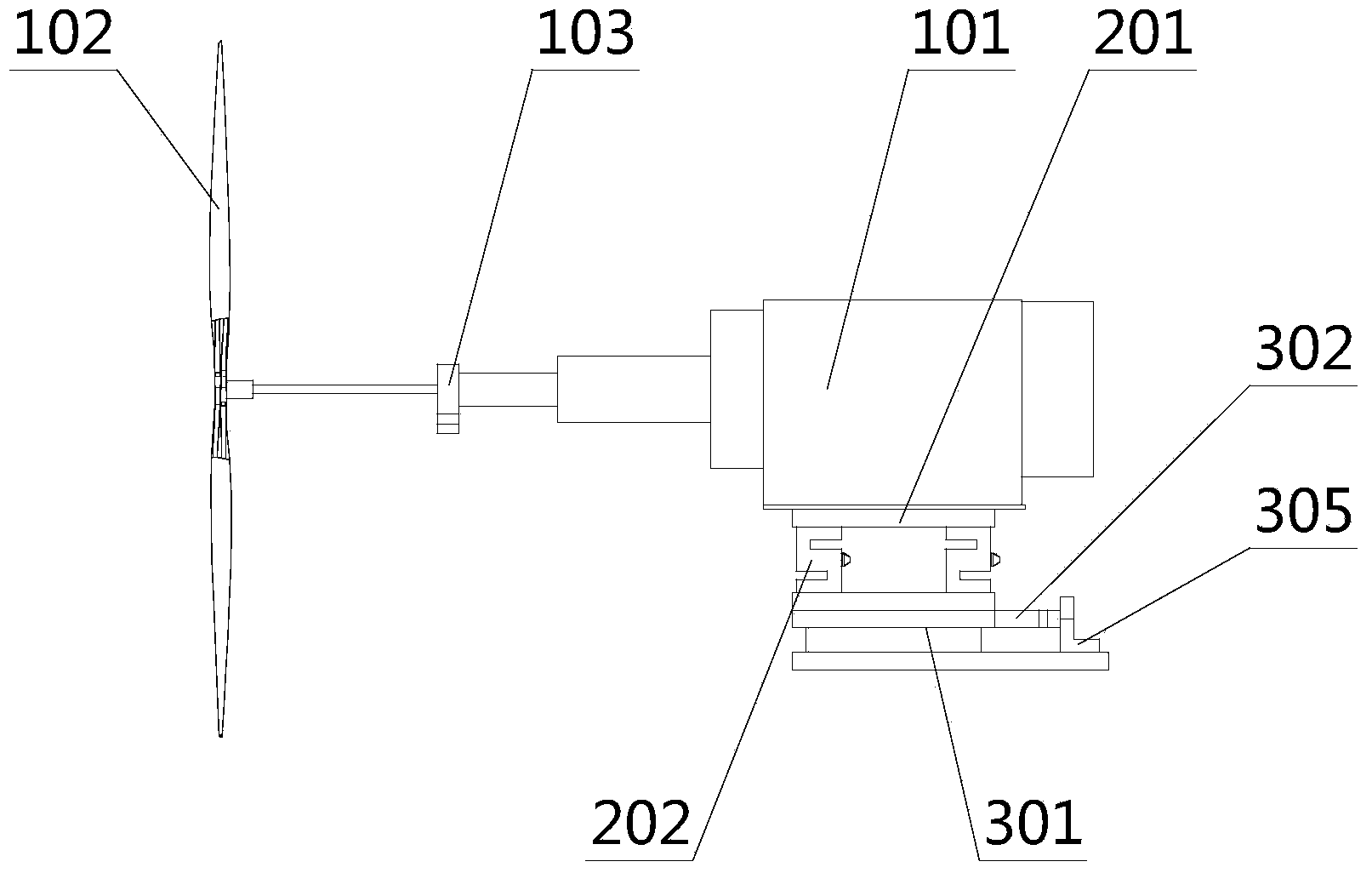

[0045] figure 1 The structural representation of the combined propeller thrust torque measuring device provided for Embodiment 1 of the present invention; please refer to figure 1 , Embodiment 1 of the present invention provides a combined propeller thrust torque measurement device, which is mainly used in vehicle-mounted tests to test the dynamic characteristics of the propeller 102 .

[0046] The combined propeller thrust torque measurement device includes a motor 101, a propeller 102 and a sensor balance. The sensor balance includes a vertical tension-pressure measurement mechanism 201 and a horizontal tension-pressure measurement mechanism 301 . The output shaft of the motor 101 is connected with the propeller 102 through the push-pull force bearing seat 103 . The vertical tension pressure measurement mechanism 201 is arranged under the motor 101 , and the horizontal tension pressure measurement mechanism 301 is arranged under the vertical tension pressure measurement me...

Embodiment 2

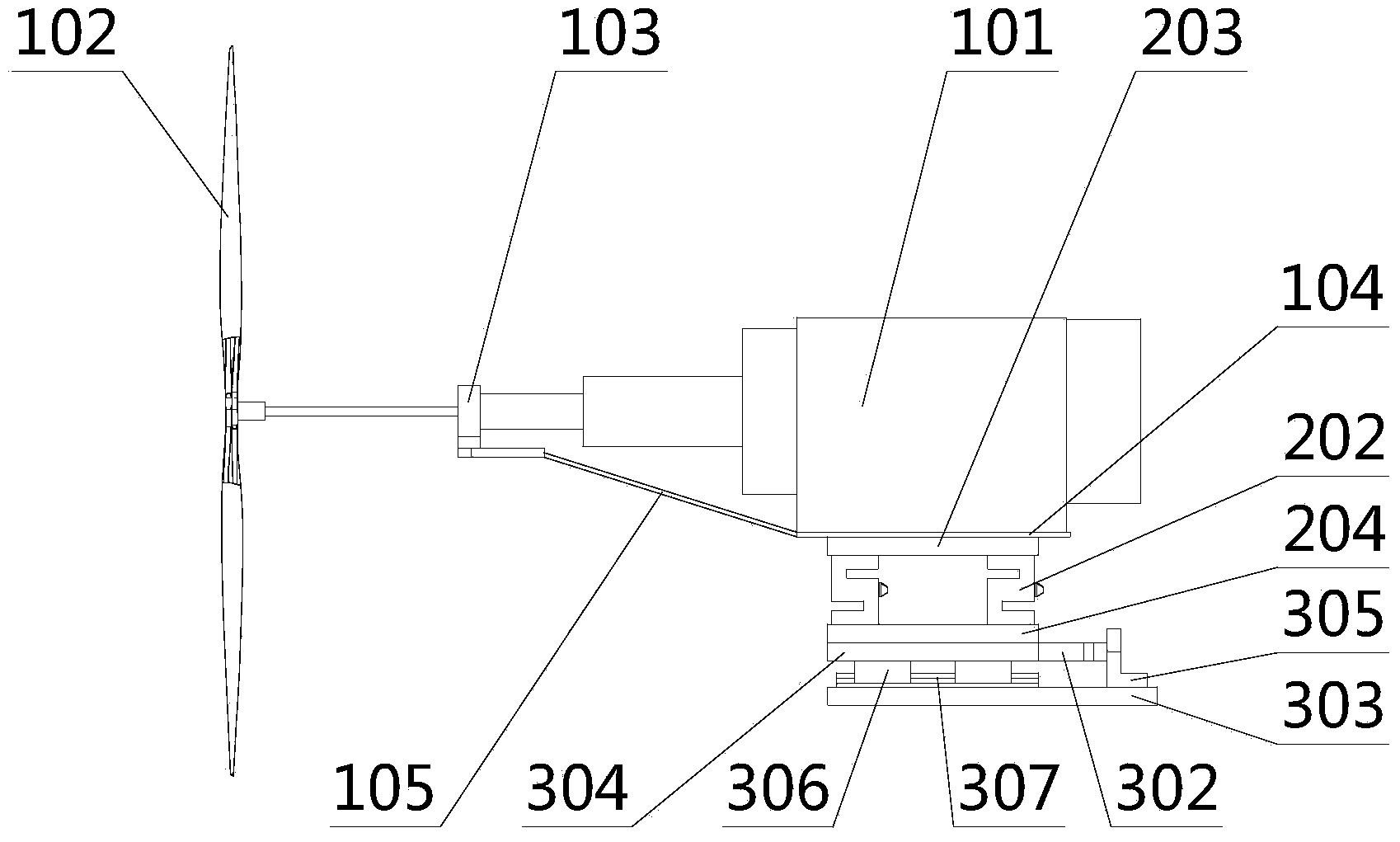

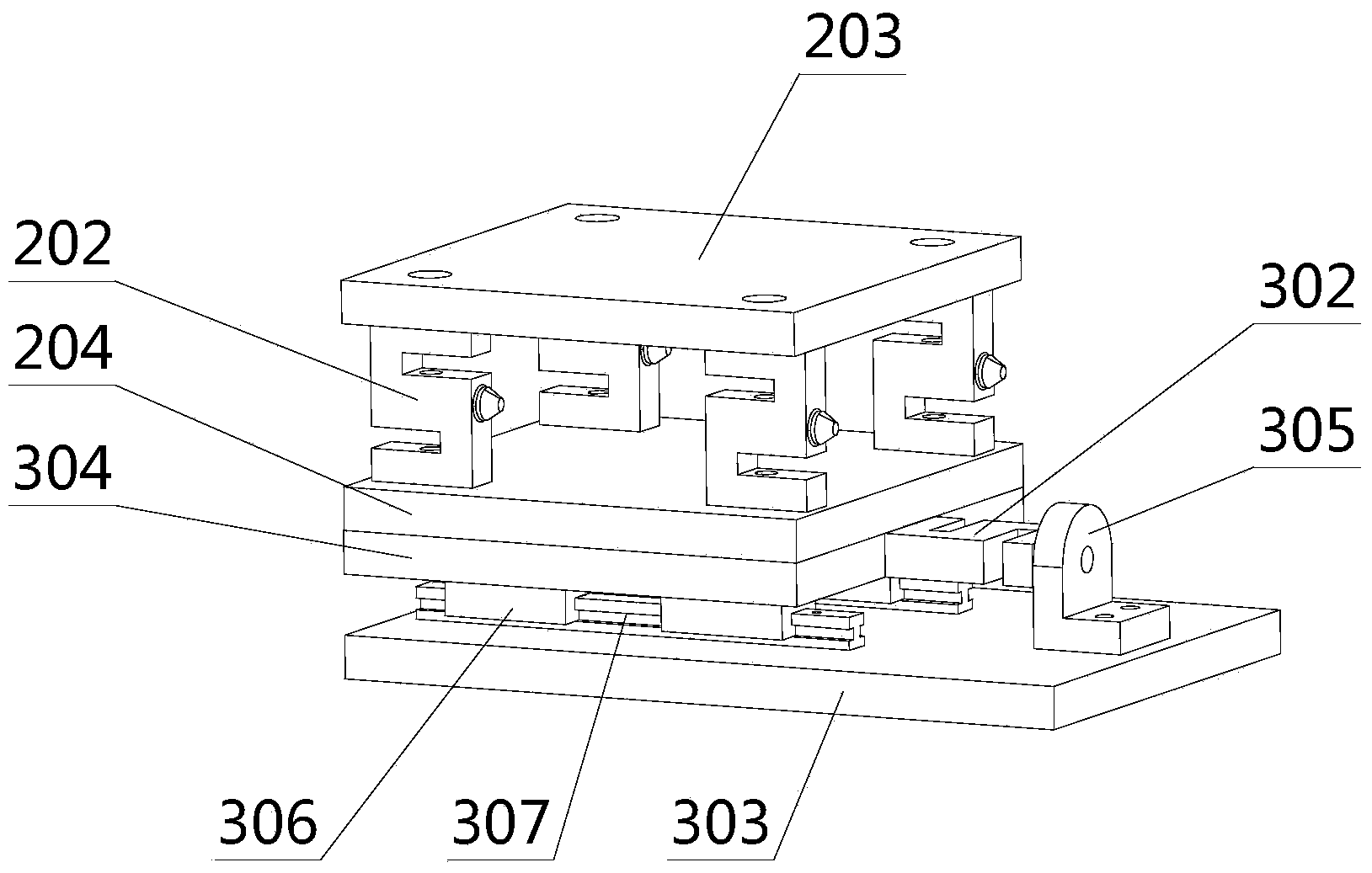

[0050] figure 2 A schematic structural view of the combined propeller thrust torque measuring device provided in Embodiment 2 of the present invention; image 3 The structure diagram of the sensor balance of the combined propeller thrust torque measuring device provided for Embodiment 2 of the present invention; please refer to figure 2 and image 3 , Embodiment 2 of the present invention provides a combined propeller thrust torque measurement device, the combined propeller thrust torque measurement device contains all the technical features of the combined propeller thrust torque measurement device provided in Embodiment 1, and the embodiment 2 provides The combined propeller thrust torque measurement device also includes the following technical features:

[0051] see figure 2 and image 3 , the horizontal tension pressure measurement mechanism 301 includes a bottom plate 303 , a connecting lower plate 304 and a horizontal tension pressure sensor 302 . The horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com