Insulation pull rod press-fitting tool and method

A technology of insulating pull rods and press-fitting tooling, which is applied in the direction of emergency protection devices, emergency protection device manufacturing, and electrical components. The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

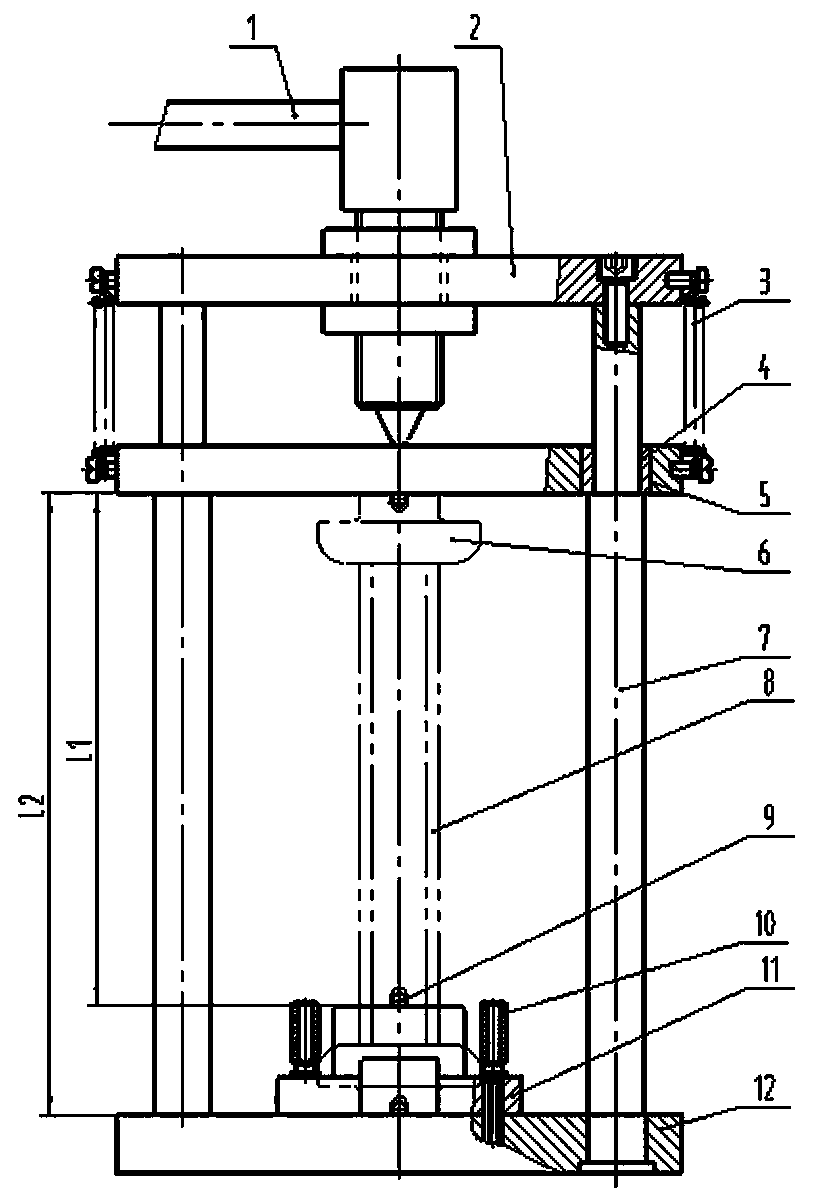

[0017] An embodiment of the insulating rod pressing tooling in the present invention is as figure 1 As shown, it includes a base 12 , a guide column 7 , a press-fit pad 11 , a limit pressure head 5 , a connecting plate 2 and a hydraulic puller 1 .

[0018] The press-fit pad 11 is a plate-shaped structure, which is detachably arranged on the base 12 of the plate-shaped structure through the positioning pin 10; the guide column 7 is a stepped shaft structure, fixed on the base 12 along the thickness direction of the press-fit pad 11 and connected with the base 12 vertical. The guide column 7 includes a support section close to the base 12 and a guide section away from the base 12. The limit pressure head 5 is a plate-shaped structure and guides and moves the guide sleeve set on the guide column 7 through the guide sleeve 4 fixed thereon. paragraph. The diameter of the support section is larger than the diameter of the guide section, forming a ring platform for blocking and mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com