Optimized dispersion method for lithium battery positive electrode slurry, and slurrying device thereof

A positive electrode slurry and lithium battery technology, applied in chemical instruments and methods, measuring devices, mixing methods, etc., can solve the problems of adverse effects on the comprehensive performance of lithium batteries, insufficient and uniform dispersion, etc., to increase the detection range and avoid excessive The effect of more loss and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

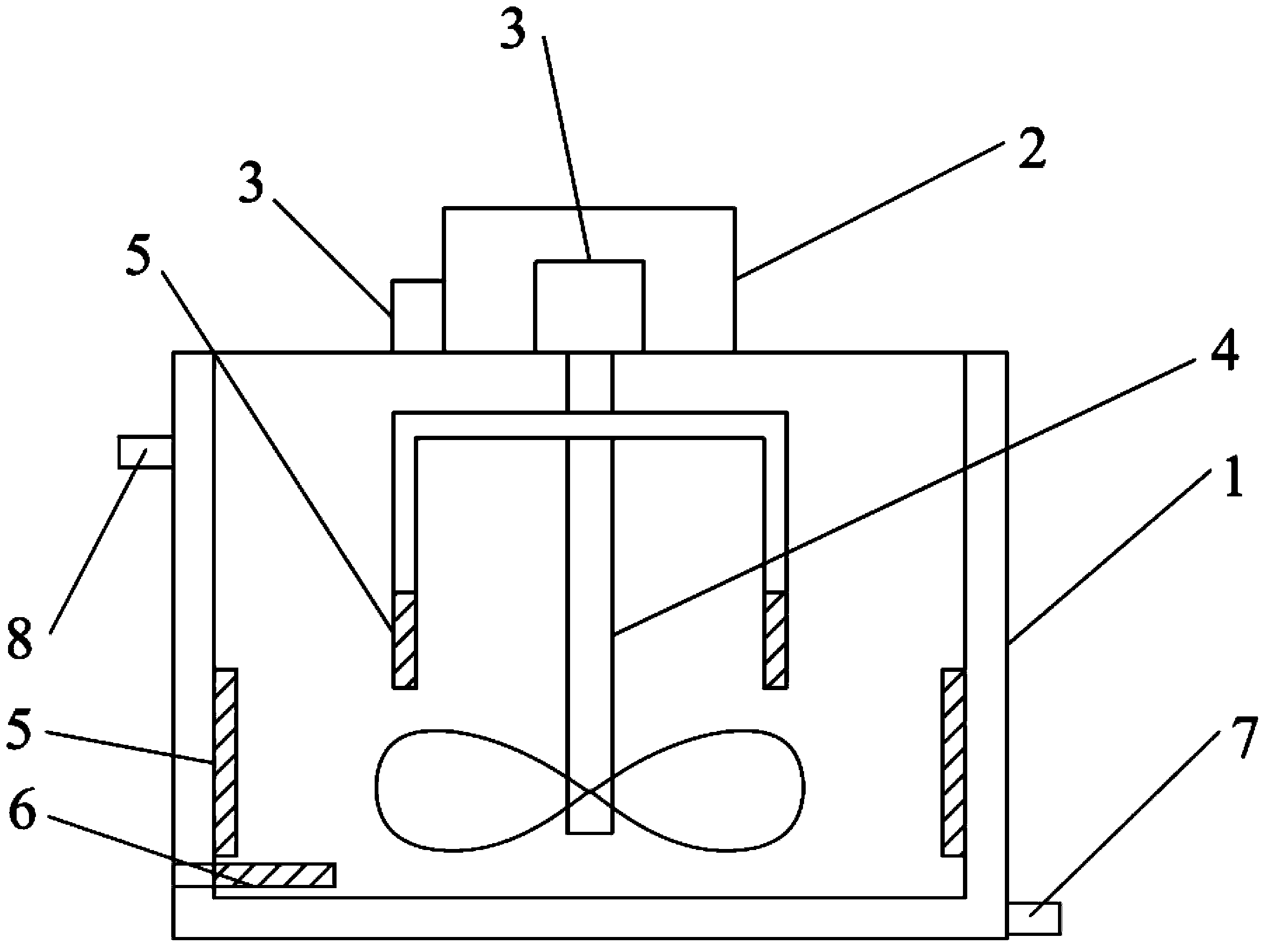

Image

Examples

Embodiment 1

[0026] A method for optimizing the dispersion of lithium battery cathode slurry, comprising the following steps:

[0027] 1) Disperse the slurry with different proportions fully and evenly in the slurry through a small test in advance, and measure the conductivity of the slurry at different temperatures in this state;

[0028] 2) Store and preset the data obtained in step 1) as a reference value in the controller connected to the conductivity tester;

[0029] 3) Monitor the conductivity of the slurry at different positions in the pulping device at different temperatures in real time through the conductivity tester, and compare the obtained data with the preset reference value in the controller to evaluate the uniformity of the slurry , when the real-time monitored conductivity matches the preset reference value, the pulping end time is determined. Among them, two conductivity testers are used and the test electrodes of the two conductivity testers are uniformly fixed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com