Mixed injecting mechanism

A material injection and auxiliary material technology, applied in the field of dairy processing equipment, can solve the problems of small promotion, high production cost, and large coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

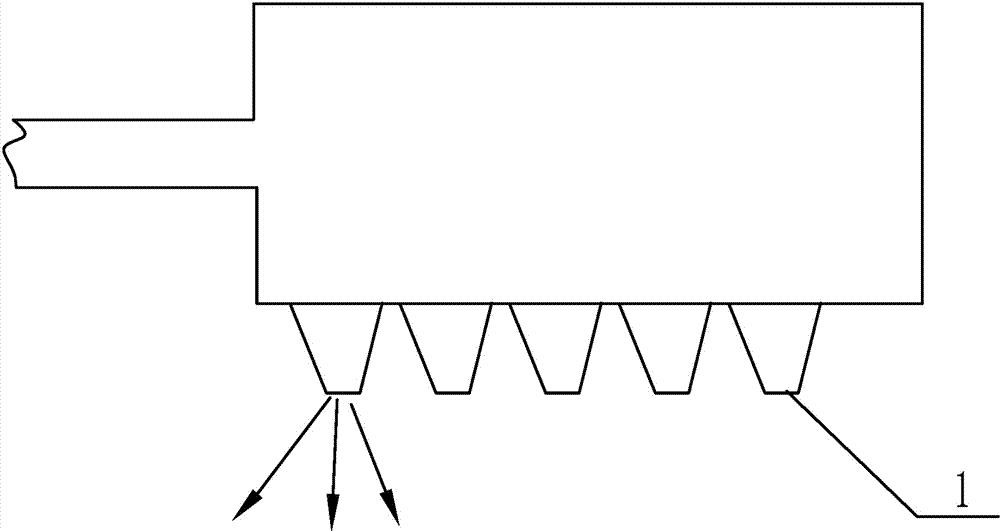

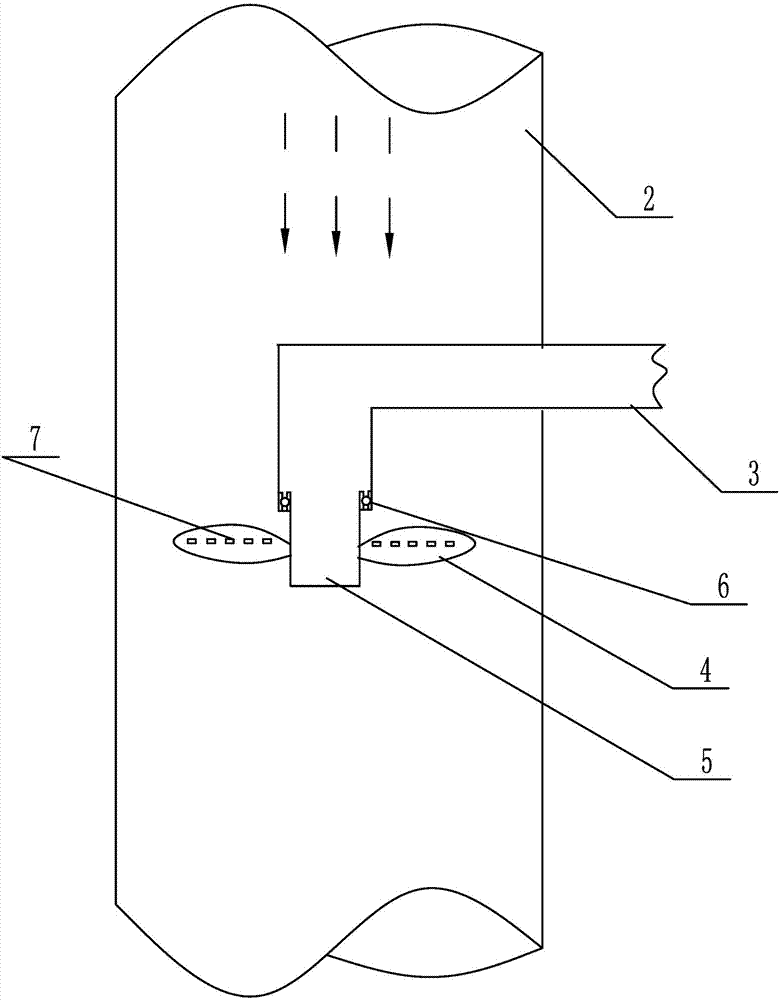

[0026] Such as figure 2 , image 3 Shown, the mixing injection mechanism of the present invention includes

[0027] Raw milk perfusion tube 2, diameter 180cm;

[0028] Auxiliary material perfusion pipe 3, the output end of which penetrates into the reactor, with a pipe diameter of 25cm;

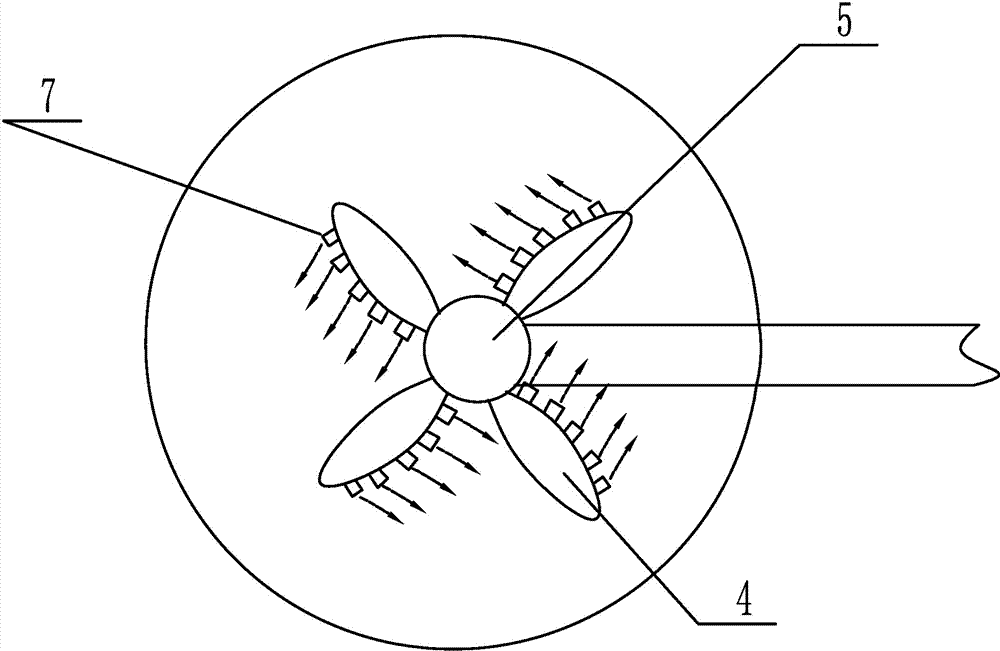

[0029] The output fan blade is located in the raw milk perfusion pipe. The output fan blade includes a central tube 5 and a group of long tubes 4. One port of the central tube 5 (diameter 18 cm) communicates with the output port of the auxiliary material perfusion tube 3 and passes through the bearing 6. Rotate connection, the other end of the central tube 5 is closed, the long tube 4 communicates with the central tube 5 and is evenly distributed on the side wall of the central tube 5 in the circumferential direction; the size of each long tube 4 is the same, and the length is 40 cm, and together form a spiral wind blade ; The longitudinal direction of the strip tube 4 is evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com