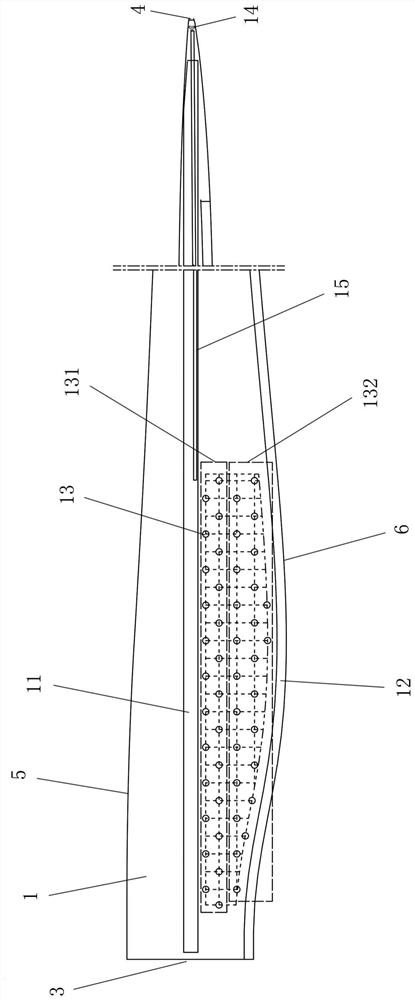

Blade, wind turbine and method of operation

A technology for wind turbines and blades, which is applied in wind turbines, control of wind turbines, and wind power generation. It can solve problems such as blade running stalls, achieve the effects of increasing power generation, solving running stall problems, and suppressing aerodynamic transitions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

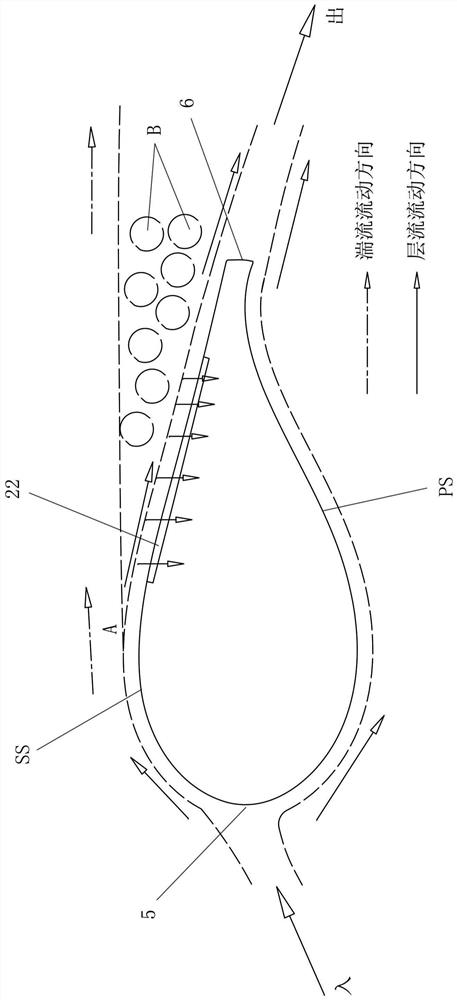

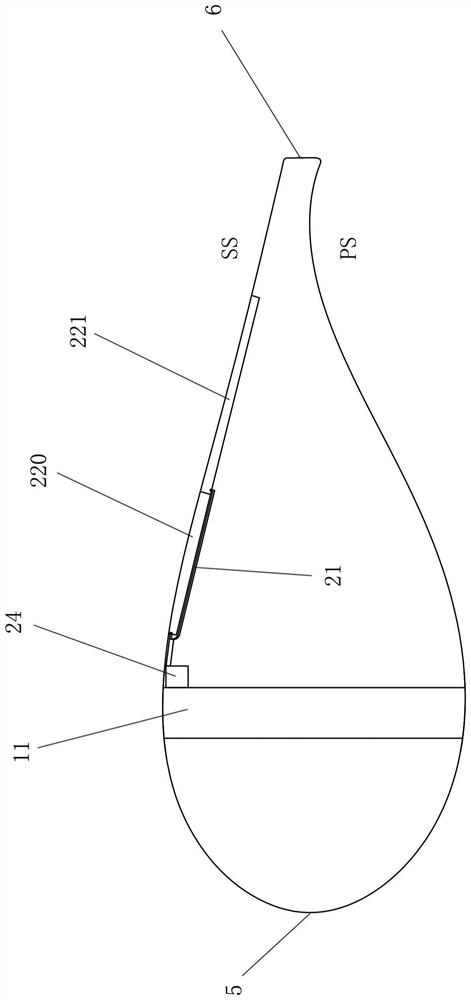

Embodiment Construction

[0026] At present, there are two main types of stall control methods: 1) active stall control methods based on specific control strategies; 2) control methods for pneumatic accessories such as vortex generators (VGs). Optimizing the control strategy is an important means to avoid stall, mainly through blade pitch control to reduce the local angle of attack at each section of the blade in the spanwise direction, so as to keep away from stall, but it will also lose airfoil lift, resulting in loss of power generation; eddy currents occur The VG is a widely used pneumatic accessory. The VG is used to mix the velocity near the wall or to a certain degree to make the velocity near the wall evenly blended, which can effectively increase the stall critical angle of attack, but it is worth noting that , Although the vortex generator can increase the maximum lift and delay the stall, it will also increase the drag by 10% to 30%, and if VG is applied at the blade tip, it will bring additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com