A Design Method of Shrinkage Ratio for Precision Casting Mold with Multi-blade Guide Vanes

A design method and technology of shrinkage rate, applied in the direction of casting molding equipment, casting mold, casting mold composition, etc., can solve the problem of over-tolerance of channel area of multi-leaf group blade castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Example 1: Five-stage guide vanes in five-blade group

[0097] (1) Contour size of the guide vane of a certain five-blade group:

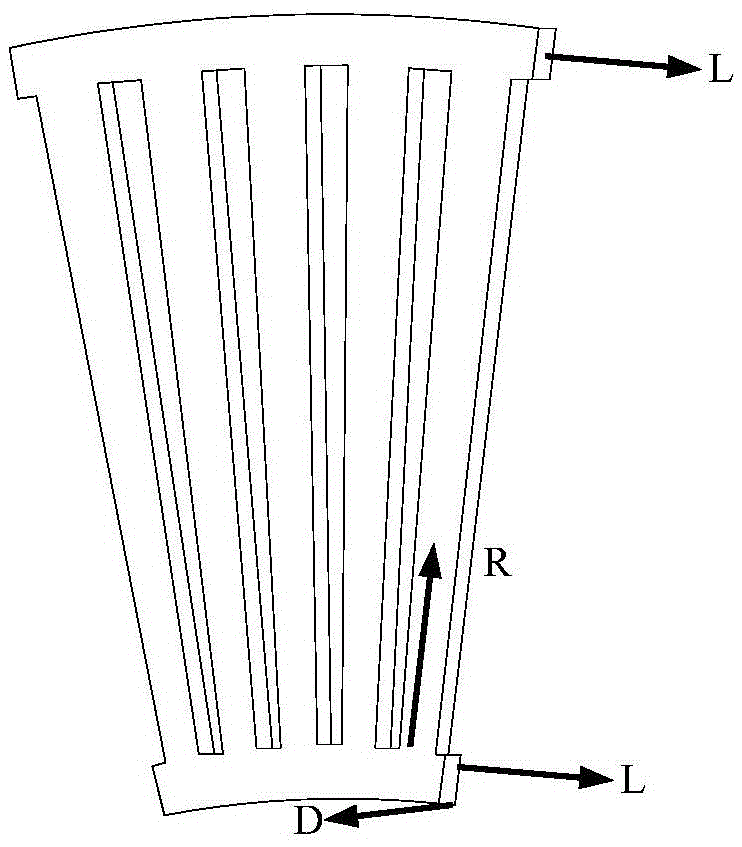

[0098] Arc length of upper edge plate L 2 It is about 140mm, the arc length L1 of the lower edge plate is about 90mm, the width D of the upper and lower edge plates is about 30mm-40mm, and the blade body length L=R 2 -R 1 It is about 220mm, and the total radian of the blade group is 4α=16.3636°.

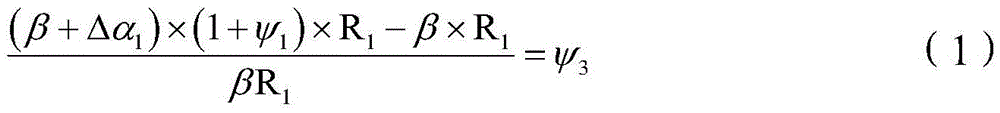

[0099] (2) Select the shrinkage size

[0100] According to the characteristics of the on-site wax material in the actual production process, the shrinkage rate of the casting mold with a dimension length of 90mm-140mm is 2.1%, the length is 30mm-40mm, 2%, and the length is 220mm, 2.4%.

[0101] That is, ψ 1 = 2.4%, ψ 2 = ψ 3 = 2.1%, ψ 4 = 2%.

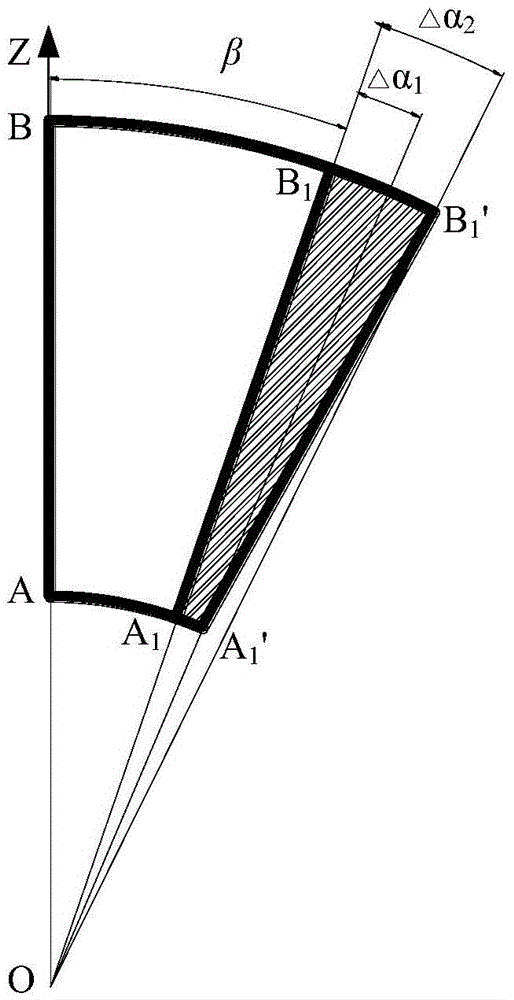

[0102] (3) Mold shrinkage design

[0103] In the D direction: 2% enlargement in the width direction of the upper and lower edge plates.

[0104] In the R direction: 2.4% enlargement in the directi...

Embodiment 2

[0107] Example 2: Three-stage guide vanes in five-leaf group

[0108] (1) Outline size of three-stage guide vanes in a five-blade group

[0109] Arc length of upper edge plate L 2 It is about 145mm, the arc length L1 of the lower edge plate is about 90mm, the width D of the upper and lower edge plates is about 20mm-40mm, and the length of the blade body L=R 2 -R 1 It is about 180mm, and the total radian of the blade group is 4α=17.1429°.

[0110] (2) Select the shrinkage size

[0111] According to the characteristics of the on-site wax material in the actual production process, the shrinkage rate of the casting mold with a dimension length of 90mm-145mm is 2.1%, the length is 20mm-40mm, 2%, and the length is 180mm, 2.3%.

[0112] That is, ψ 1 = 2.3%, ψ 2 = ψ 3 = 2.1%, ψ 4 = 2%.

[0113] (3) Mold shrinkage design

[0114] By calculation, the offset angle When N is 1, Δα=-30", and when N is 2, Δα=-60".

[0115] Shrinkage enlargement process: On the premise of ensuri...

Embodiment 3

[0116] Example 3: Four-stage guide vanes in five-leaf group

[0117] (1) Outline dimensions of four-stage guide vanes in a five-blade group

[0118] Arc length of upper edge plate L 2 About 145mm, the arc length L of the lower edge plate 1 It is about 85mm, the width D of the upper and lower edge plates is about 20mm~40mm, and the length of the blade body L=R 2 -R 1 It is about 200mm, and the total radian of the blade group is 4α=16.3636°.

[0119] (2) Select the shrinkage size

[0120] According to the characteristics of the on-site wax material in the actual production process, the shrinkage rate of the casting mold with a size of 85mm to 145mm is 2.1%, the length is 20mm to 40mm, 2%, and the length is 200mm, 2.4%.

[0121] That is, ψ 1 = 2.4%, ψ 2 = ψ 3 = 2.1%, ψ 4 = 2%.

[0122] (3) Mold shrinkage design

[0123] By calculation, the offset angle When N is 1, Δα=-43", and when N is 2, Δα=-86".

[0124] Shrinkage enlargement process: On the premise of ensuring th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com