Flanging mould, assembling mould, and paving method and moulding method of moulding material

A flanging mold and laying method technology, which is applied in the field of fan blade manufacturing, can solve the problems of hand lay-up air bubbles, the flanging mold is not easy to fix, and delamination, and achieve the effect of reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

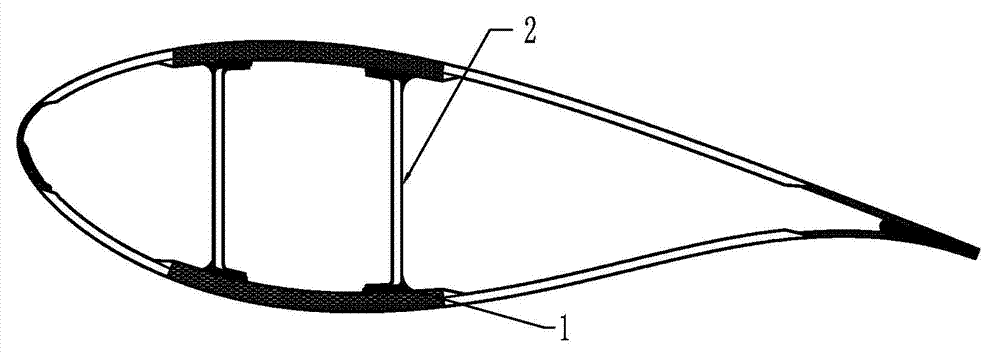

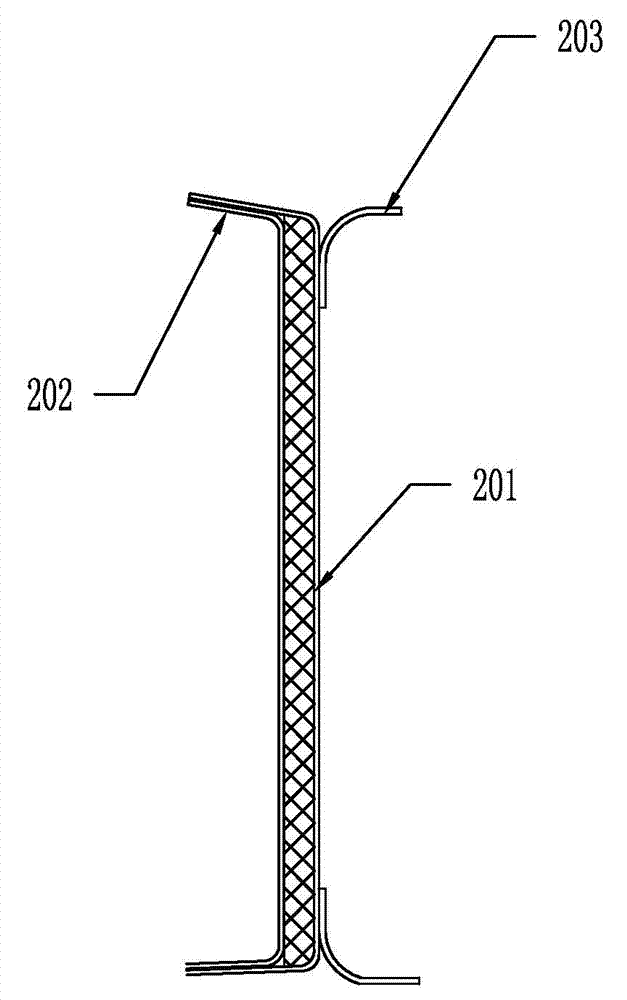

[0028] First introduce the flanging mold of the embodiment of the present invention below, Figure 4 It is a structural schematic diagram of the flanging mold in the combined mold of the I-shaped web of the fan blade according to the embodiment of the present invention.

[0029] Such as Figure 4 As shown, the flanging mold of the fan blade I-shaped web provided by the embodiment of the present invention has the following specific features: the flanging mold has an integrated mold surface, and the mold surface has a pointed protrusion 320, and the pointed protrusion 320 The vertex of the flange is bounded, and the first curved surface 310 and the second curved surface 330 are formed on both sides. During the molding process, the first curved surface 310 of the flanging mold is bonded to the molding material of the turned-up part of the outer flange 203, which is used for To form the shape of the turned-up portion, the second curved surface 330 of the turn-up mold is in contac...

Embodiment 2

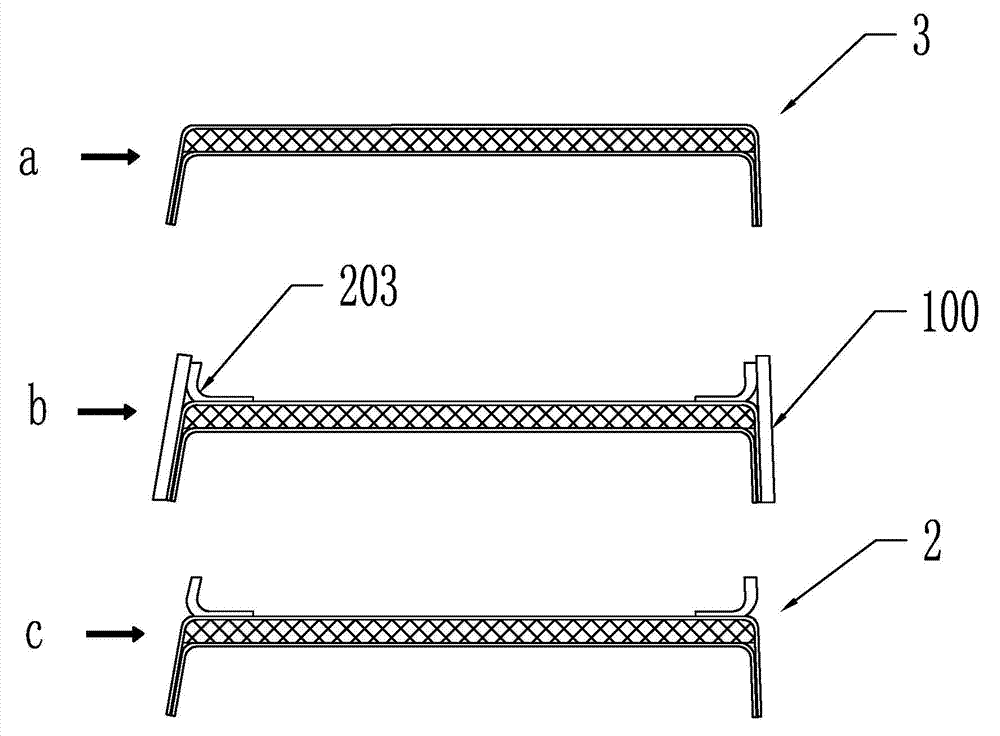

[0035] The laying method and molding method of the molding material for processing the I-shaped web of the fan blade based on the above combined mold will be introduced below.

[0036] Such as Figure 6 and Figure 8 As shown, based on the above combined mold, the flow process of the laying method of the molding material in the embodiment of the present invention is as follows:

[0037] Step 601: Lay the lower diversion net, the lower isolation film, and the first molding material for forming the web body and inward flanging in sequence on the flat mold, and the lower diversion net and the lower isolation film are covered to form the web body and inversion edge position. The state after laying is as Figure 8In process e in, the lower guide net is mainly used to guide the resin so that the resin can be evenly spread to each part of the web body and the inner flange, and the lower isolation film is used to connect the lower guide net with the first The molding material is s...

Embodiment 3

[0045] Such as Figure 7 As shown, it is a flow chart of the molding method of the fan blade I-shaped web in the embodiment of the present invention, which includes:

[0046] Step 701 of laying the film-forming material: In this step, the molding material is laid by using the laying method of the molding material in the above-mentioned embodiment 2, and the shape after laying is as follows Figure 8 Shown in process f.

[0047] Step 702 of forming a sealed perfusion space: setting a vacuum perfusion auxiliary component on the upper guide net and sealing the gap between the flanging mold and the flat mold to form a sealed perfusion space for vacuum perfusion. Among them, the vacuum auxiliary components mainly include components such as pipelines required for forming a sealed perfusion space and subsequent perfusion, such as vacuum membranes, glue injection pipelines, and vacuum pipelines. Specifically, a guide tube is arranged on the upper guide net, and a vacuum film is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com