Method for manufacturing double-structure rod

A manufacturing method and technology for structural rods, which are applied in the field of rod manufacturing, can solve the problems of complicated operation steps, increased overall cost, and decreased appearance, and achieve the effects of reducing raw materials, strong elasticity, and reducing the number of scraps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In conjunction with the above drawings, a more specific description of the present invention is as follows:

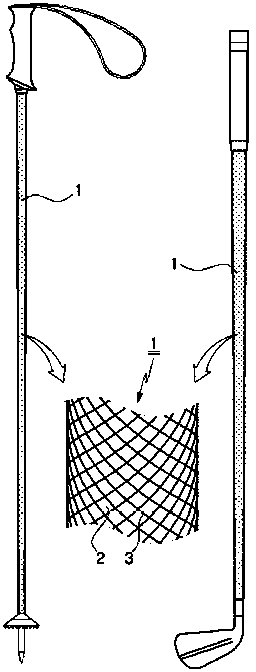

[0022] Such as figure 1 As shown, the upper part of the ski pole and trekking pole is equipped with a handle, the lower part is equipped with a ball basket and the grazing part, the upper part of the golf club is equipped with a handle, and the lower part is installed with a magnetic head. The rod 1 manufactured by the method is applicable to various products in multiple fields such as fishing rods, ice hockey sticks, poles for tents, and archery, in addition to the above ski poles, trekking poles and golf clubs.

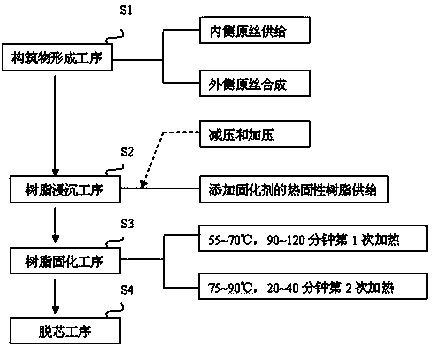

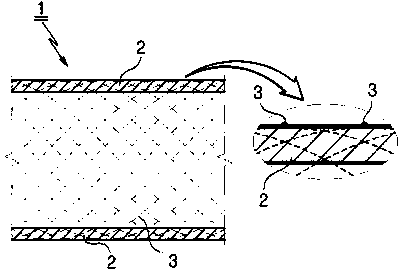

[0023] The various rods 1 involved in the present invention are made by using raw filaments such as carbon fibers to be synthesized in a weaving manner, and then immersed in various resins for curing. The manufacturing cost of the pole 1 improves the durability of the pole 1, realizes light weight, and allows the design to be varied, making the manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com