Polygon packaging structure

A technology of polygonal structure and packaging structure, applied in the directions of packaging, transportation and packaging, packaging of vulnerable items, etc., can solve the problems of increasing the operation steps of the staff, the large size of the large packaging box, and the difficulty of the staff to operate, etc., to improve the space utilization. efficiency, reducing packaging costs, and the effect of low packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better illustrate the technical characteristics and structure of the present invention, the following is a detailed description in conjunction with preferred embodiments of the present invention and accompanying drawings.

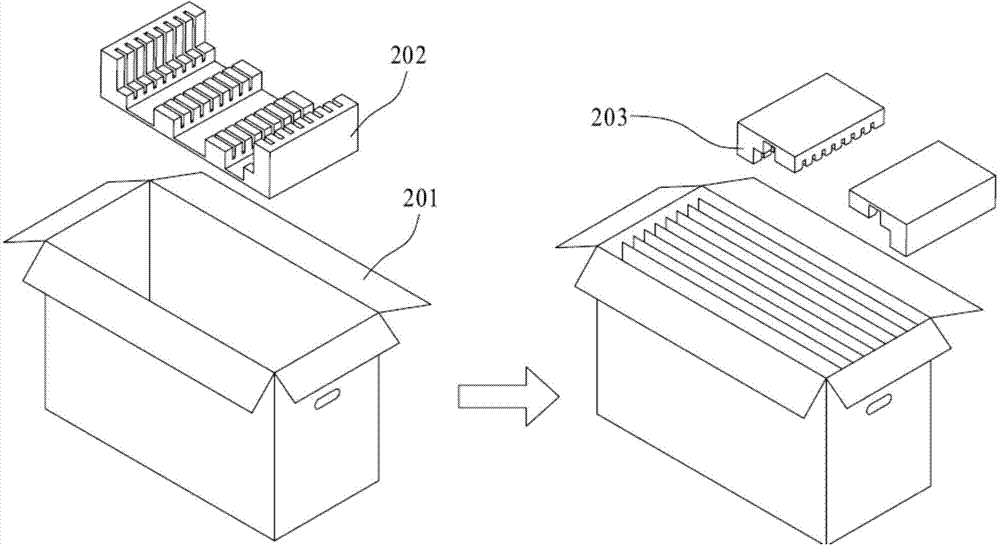

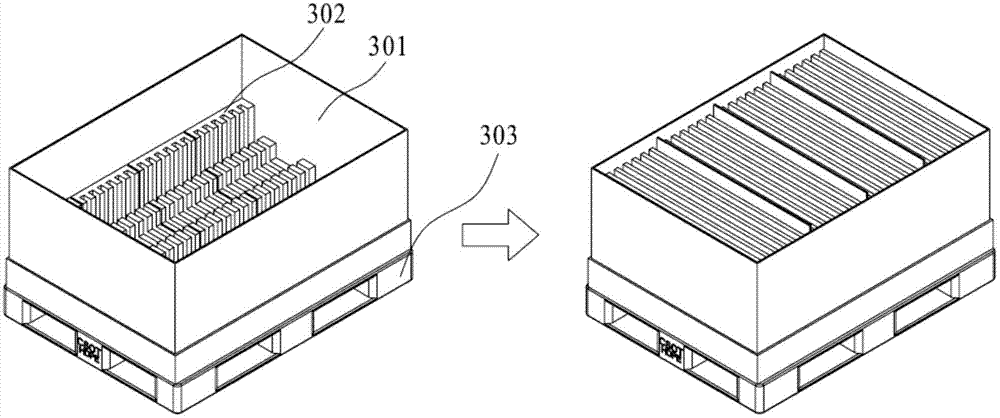

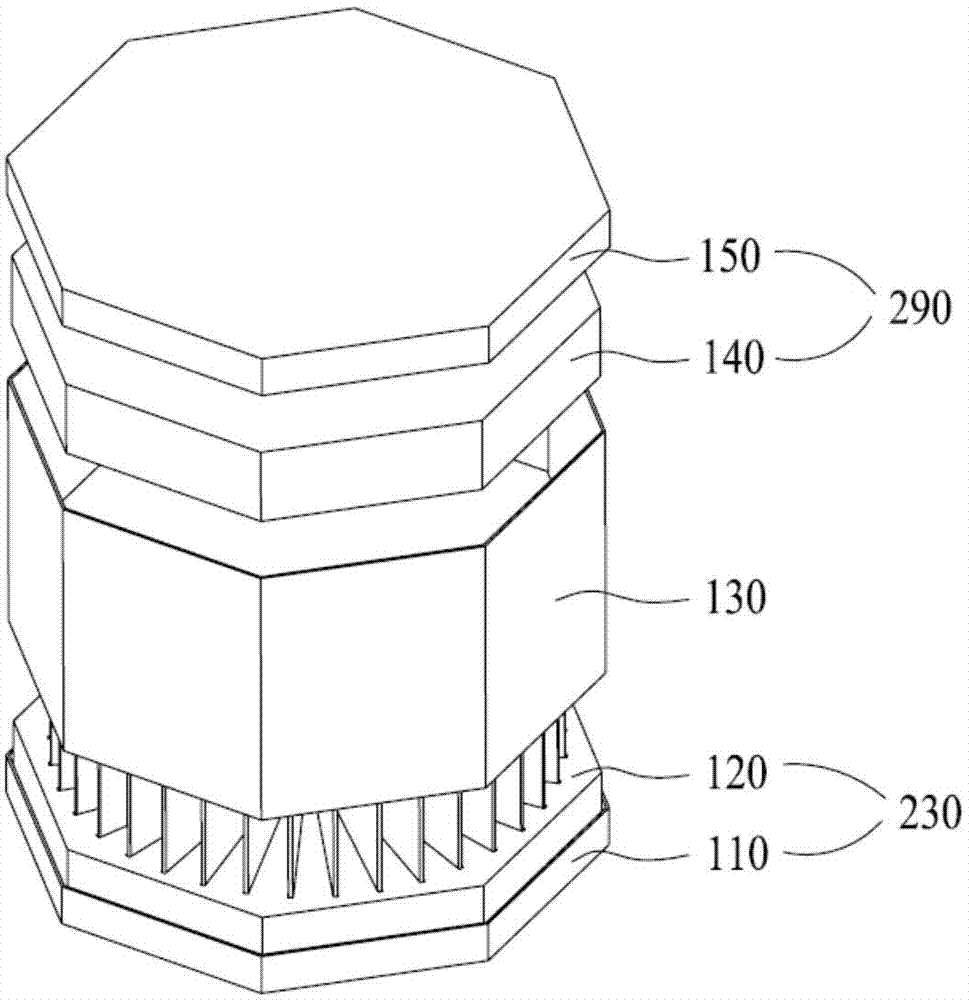

[0037] refer to image 3 , the polygonal packaging structure provided by the present invention is used for packaging sheet carriers, at least comprising a buffer base 230 at the bottom and a buffer top cover 290 at the top, wherein the buffer base 230 includes a cushion 120 and a base 110, and the cushion 120 and the base 110 Both are polygonal structures, and the buffer pad 120 is set inside the base 110; the buffer top cover 290 includes a buffer cover 140 and a top cover 150, both of which are polygonal structures, and the buffer cover 140 is set on the top cover 150 The inside of the box body 130 is sleeved between the buffer base 230 and the buffer top cover 290, and the upper end and the lower end of the box body 130 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com