Sandy and stony construction waste gravel sand fixation structure and manufacturing method thereof

A construction waste and production method technology, applied in construction, infrastructure engineering, soil protection, etc., can solve problems affecting city appearance and environmental sanitation, and achieve the effects of simple equipment and technology, improved ecology, and no rainfall runoff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

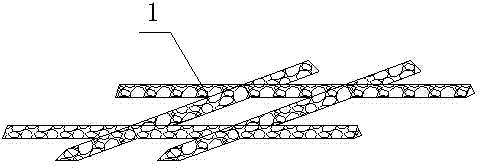

[0034] Such as figure 1 A sandy construction waste gravel sand fixation structure shown includes a grid-shaped sand barrier 1. The grid-shaped sand barrier 1 is made of crushed construction waste into 10-50mm crushed stones, and its side length is 1.5 mm. m, each side is a triangular ridge shape with a bottom width of 34cm and a height of 17cm.

[0035] Wherein, the side length of the sand barrier can range from 1-2m, and the size range of the triangular ridge is 30-40cm in bottom width and 15-20cm in height.

[0036] The production of the construction waste gravel sand-fixing structure is to crush a large amount of sandy construction waste formed by the demolition of nearby towns into 10-50mm crushed gravel with an energy-saving jaw crusher, and make the crushed gravel with a bottom width of 30-40cm and a height of 30-40cm. 15-20cm triangular ridge shape, 1-2m square grid-shaped sand barrier.

[0037]

Embodiment 2

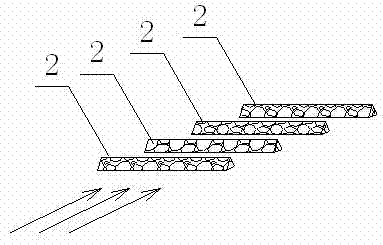

[0039] Such as figure 2 A kind of sandy construction waste gravel sand-fixing structure shown, comprises belt-shaped sand barrier 2, and this belt-shaped sand barrier 2 is made of crushed gravels of 10-50 mm by construction waste, with a bottom width of 40 cm and a height of 20 cm. Triangular ridge shape. Among them, the direction of the ridge is consistent with the local main wind direction (such as figure 2 The middle arrow points to) vertically, that is to say, the main wind will be blocked by the belt-shaped sand barrier 2 and weakened. There are several ridges parallel to each other with a distance of 2m.

[0040] The production of the construction waste gravel sand-fixing structure is to crush a large amount of sandy construction waste formed by the demolition of nearby towns into 10-50mm gravel with an energy-saving jaw crusher. Triangular ridge shape.

[0041]

Embodiment 3

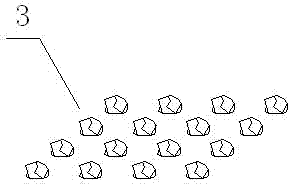

[0043] Such as image 3 A gravel sand-fixing structure of sandy and gravel construction waste is shown, including a uniformly flat sand barrier 3, which is composed of crushed construction waste into 10-50mm crushed stones, which are evenly spread On the dunes, where the coverage is between 40-60%.

[0044] The sand-stone construction waste gravel sand-fixing structure is made by crushing a large amount of sand-stone construction waste formed by the demolition of nearby cities and towns into 10-50mm crushed gravel with an energy-saving jaw crusher, and spreading them evenly on the sand dunes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com