A corrosion-resistant magnetic pump

A magnetic pump, corrosion-resistant technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of corrosion, economic losses, having to stop and replace, etc., and achieve the effect of reducing production costs, extending working hours, and extending replacement cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

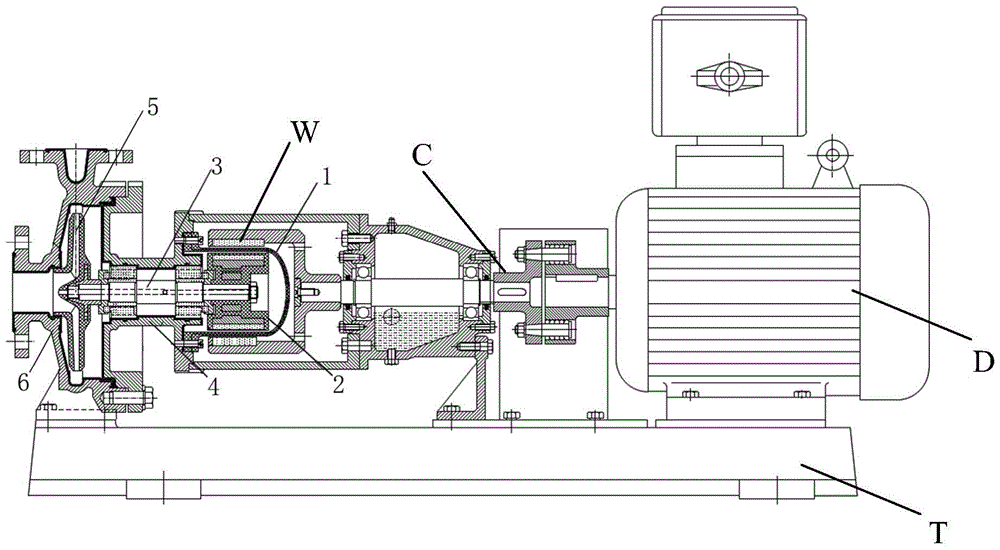

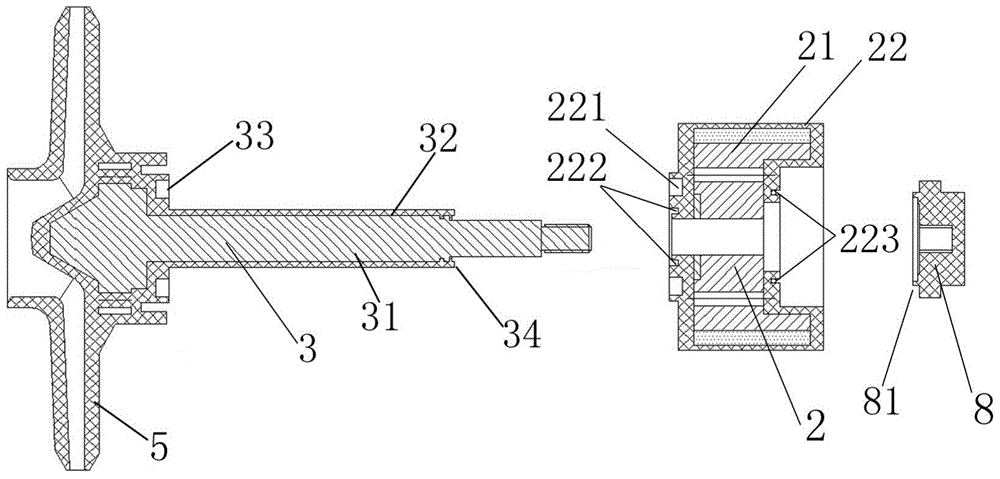

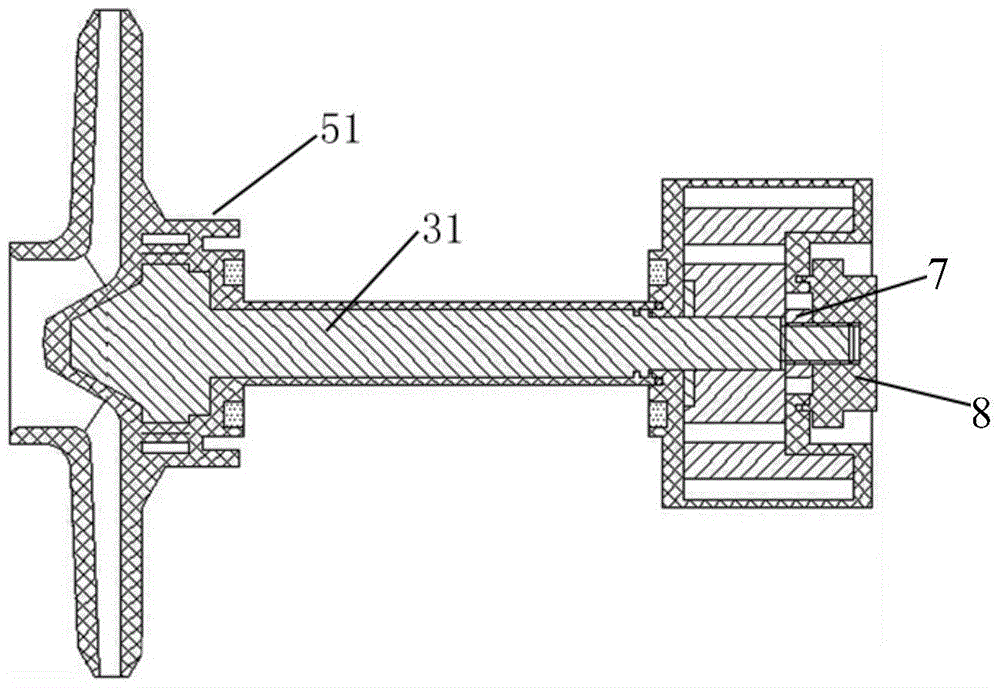

[0023] figure 1 Shown is a magnetic pump in the prior art, including a bracket T, a motor D, a transmission C, an outer magnetic assembly W, a spacer 1, an inner magnetic assembly 2, a middle body 4, and a bearing Z ( Figure 4 ), the pump shaft 3, the impeller 5, and the pump casing 6, wherein, the motor D and the transmission device C are installed on the bracket T, and the outer magnetic assembly W is installed on the transmission device C, and the inner magnetic assembly 2 is driven by the magnetic force to connect with the outer magnetic assembly. The magnetic assembly W rotates concentricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com