Strontium-containing xenogeneic bone scaffold and preparation method thereof

A bone scaffold and xenogeneic technology, applied in the field of materials, can solve the problems of long preparation period and limited strontium content, and achieve the effects of prolonging the release period, easy operation and short period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

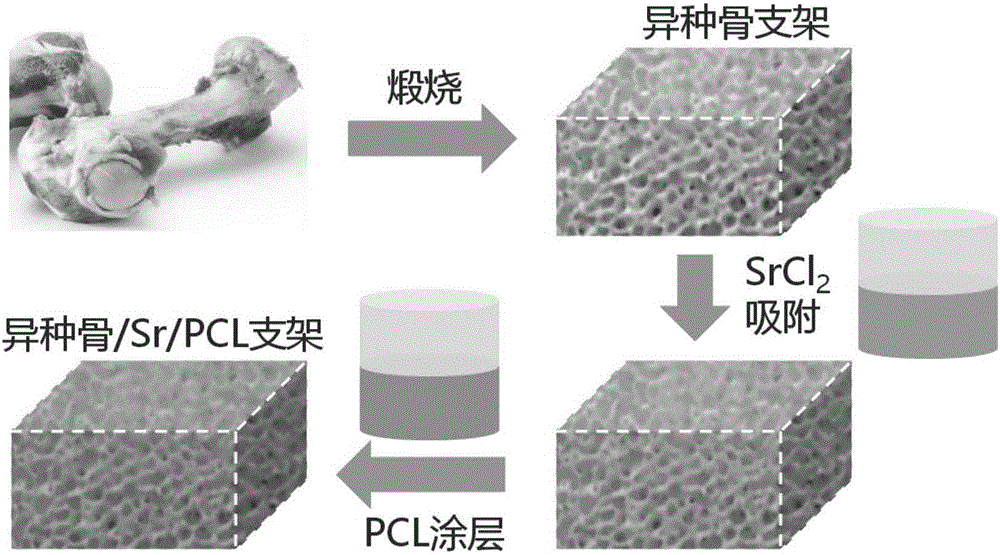

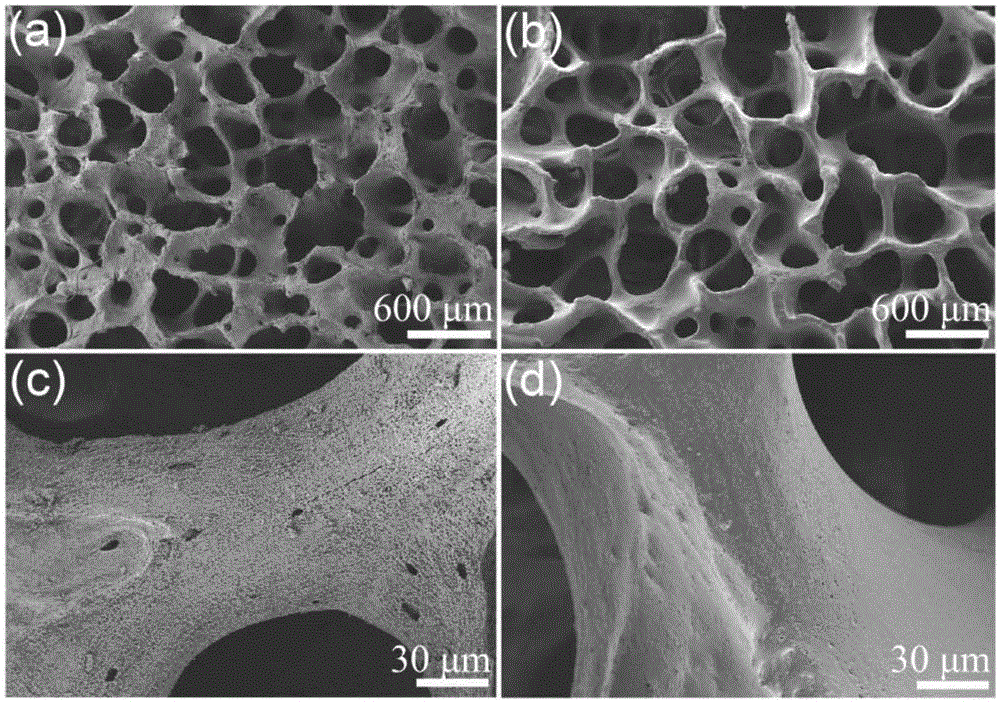

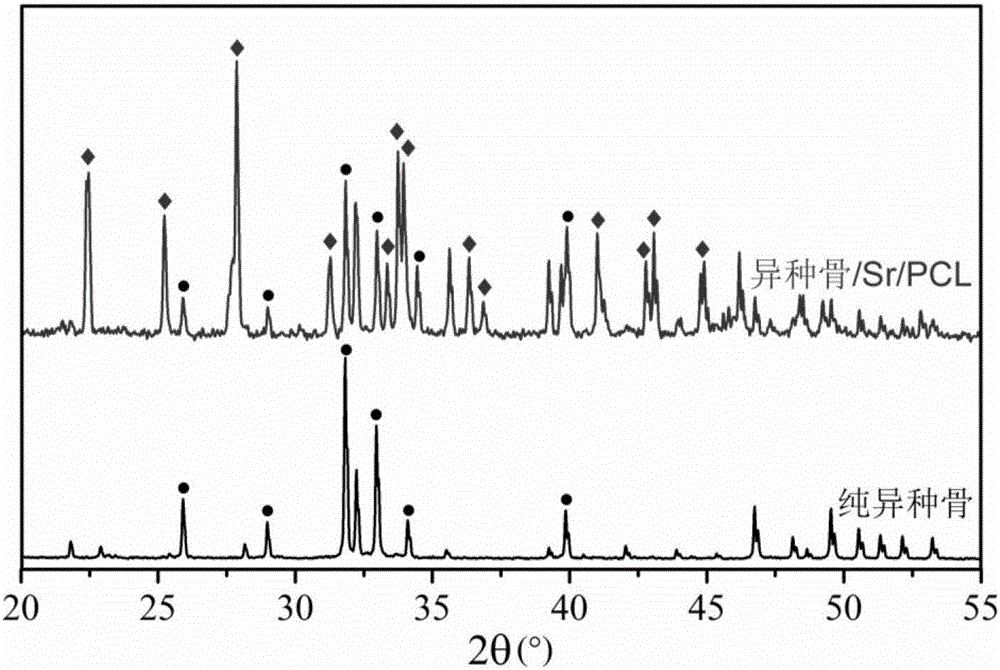

[0041] a) Select porcine femoral cancellous bone, cut into pieces, stir in 80°C water, and change the liquid every 3 hours. When the aqueous solution was bloodless, the bones were transferred to 75% (v / v) ethanol and stirred for 4 hours. The bones were then stirred in 10% (w / v) sodium hydroxide for 2 h. Finally the bones were stirred in 30% (v / v) hydrogen peroxide for 12h. The bone was washed with water, calcined at 800°C for 5 hours, and the heterogeneous bone scaffold was obtained after cooling.

[0042] b) Preparation of SrCl 2 Aqueous solution (2M), soak the scaffold in it, stir for 6 hours, absorb excess liquid, bake at 60°C for 2 hours, and obtain the heterogeneous bone / Sr scaffold.

[0043] c) Prepare an organic solution of polycaprolactone (PCL) in dichloromethane (DCM) (10%, w / v), and coat the organic solution on the heterogeneous bone / Sr scaffold. After the DCM was volatilized, it was heated at 60°C for 2 hours, and after cooling, the heterogeneous bone / Sr / PCL sc...

Embodiment 2

[0050] Select porcine femoral cancellous bone, cut into pieces, stir in 80°C water, and change the liquid every 3 hours. When the aqueous solution was bloodless, the bones were transferred to 75% (v / v) ethanol and stirred for 4 hours. The bones were then stirred in 10% (w / v) sodium hydroxide for 2 h. Finally the bones were stirred in 30% (v / v) hydrogen peroxide for 12h. The bone was washed with water, calcined at 800°C for 5 hours, and the heterogeneous bone scaffold was obtained after cooling. Prepare SrCl 2 Aqueous solution (2M), soak the scaffold in it, stir for 6 hours, absorb excess liquid, bake at 60°C for 2 hours, and obtain the heterogeneous bone / Sr scaffold. An organic solution of polycaprolactone (PCL) in dichloromethane (DCM) (15%, w / v) was prepared, and the organic solution was coated on the xenograft bone / Sr scaffold. After the DCM was volatilized, it was heated at 60°C for 3 hours, and after cooling, the heterogeneous bone / Sr / PCL scaffold was obtained and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com