Dustproof and waterproof structure of ventilator

A dustproof, waterproof, and ventilator technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems affecting heat dissipation capacity, rotor dynamic balance damage, radiator dirty, etc., to improve rotor stability, Strong anti-fouling ability, prolonging the effect of cleaning time and maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

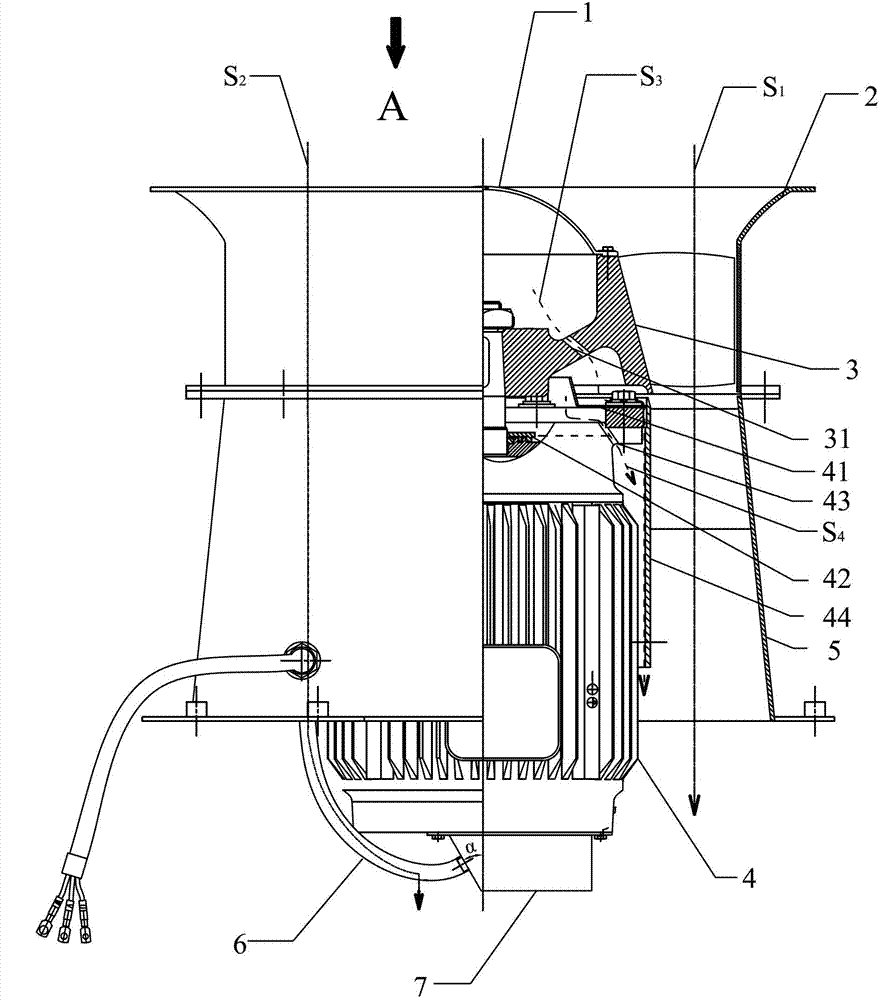

[0016] like figure 1 As shown, a dust-proof and waterproof structure for a ventilator includes a shroud 1, an upper air cylinder 2, an impeller 3, a motor 4, a diffusion cylinder 5, a cable 6, and a junction box 7, and the impeller 3 is a radial acceleration impeller, The inlet of the impeller 3 is provided with the shroud 1, and the connecting arm between the outer connecting part of the hub and the inner connecting part of the hub is provided with a drain hole I31, and the drain hole I31 is from the inside of the hub. The connecting part is a through hole opened in the inclined direction of the outer connecting part of the hub, and the sewage hole I31 can discharge impurities such as rain, snow and water (hereinafter referred to as sewage) entering the hub of the impeller 3; the main shaft of the motor 4 and the impeller 3-axis connection, the main shaft of the motor 4 is provided with a labyrinth dustproof ring 42 at a position close to the inlet of the motor 4, and the lab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com