Filter sand washing method and its system

A technology for filtering sand and cleaning water, which is applied in the field of sand cleaning to achieve the effect of prolonging the time period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

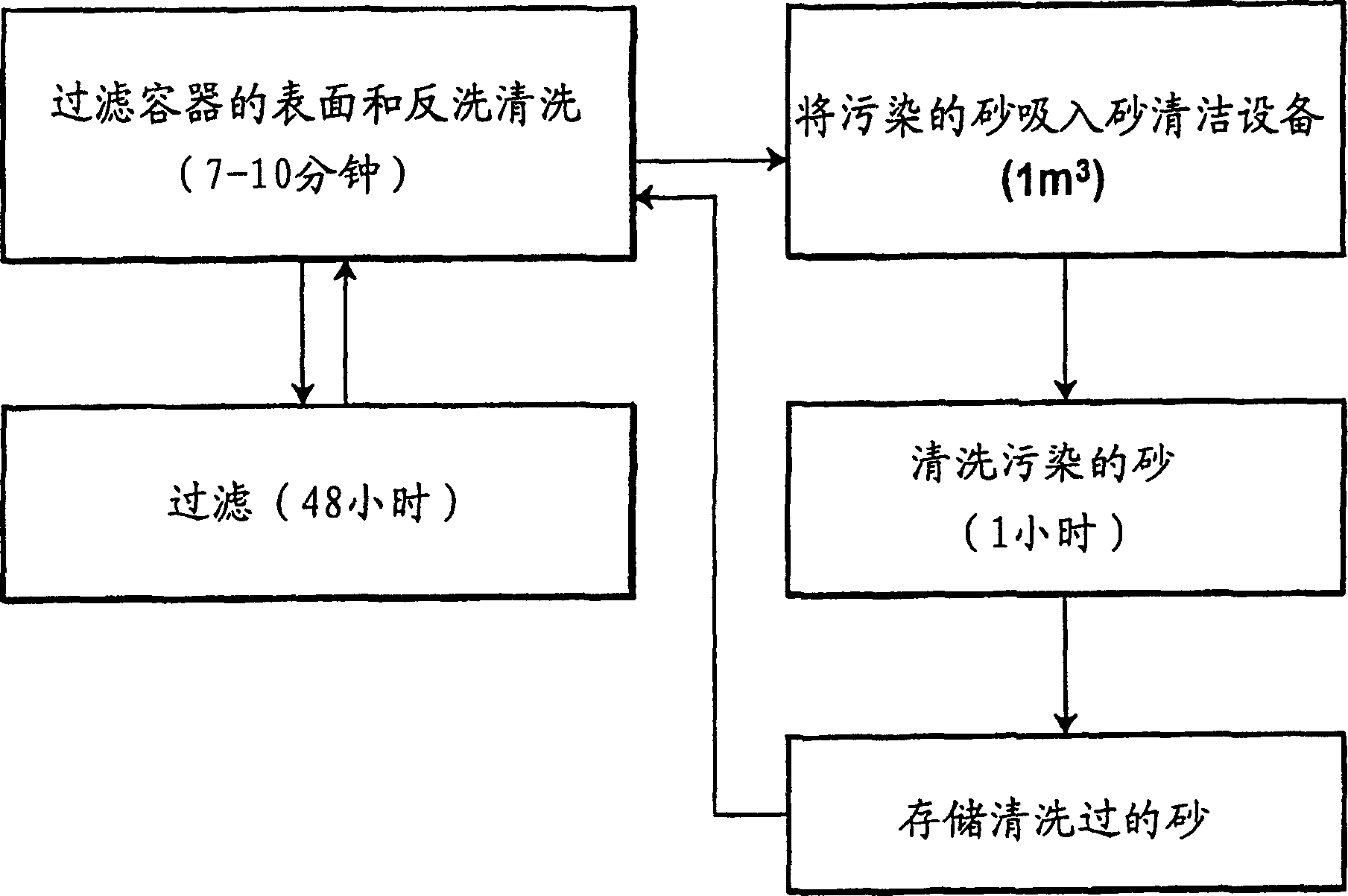

Method used

Image

Examples

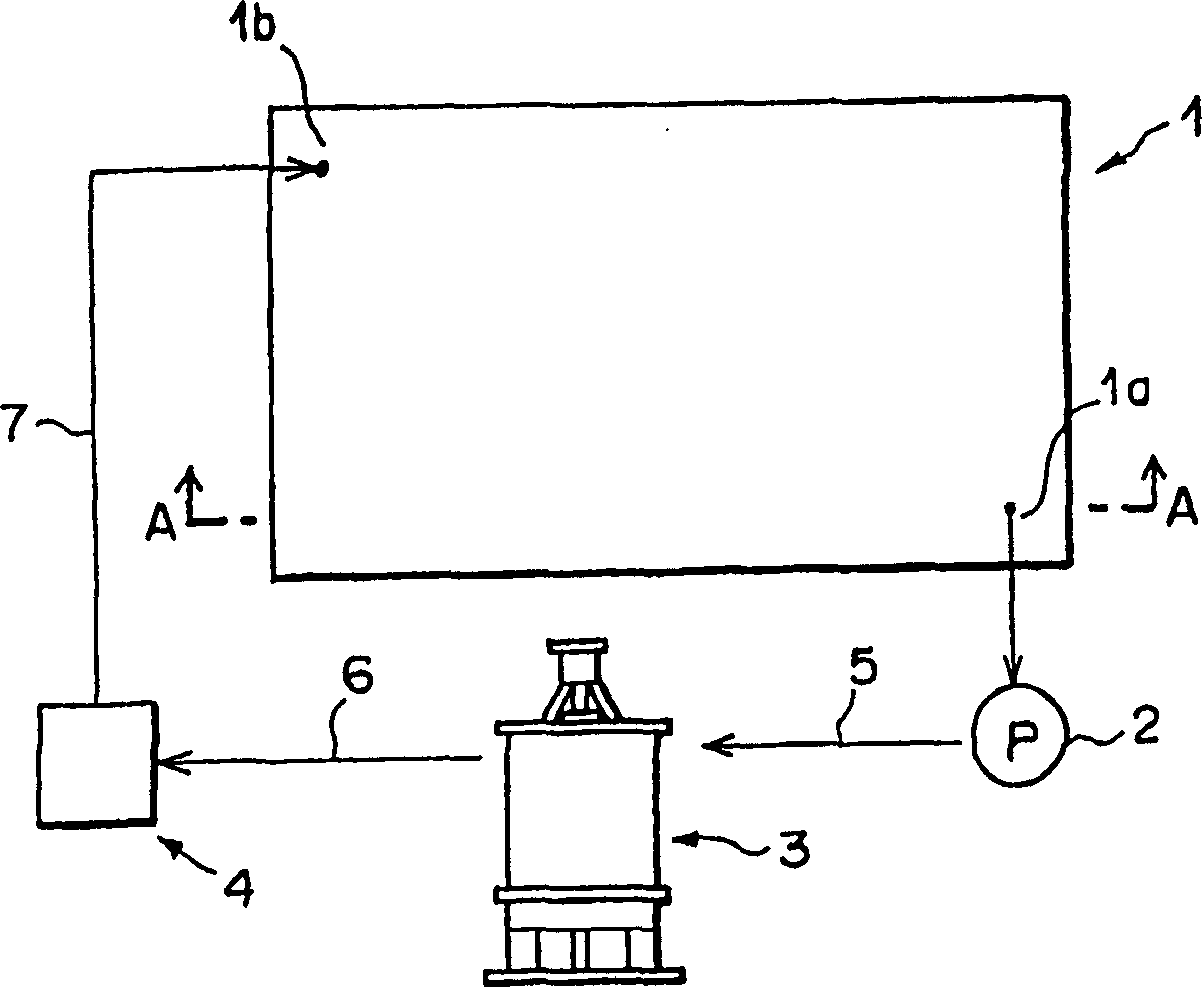

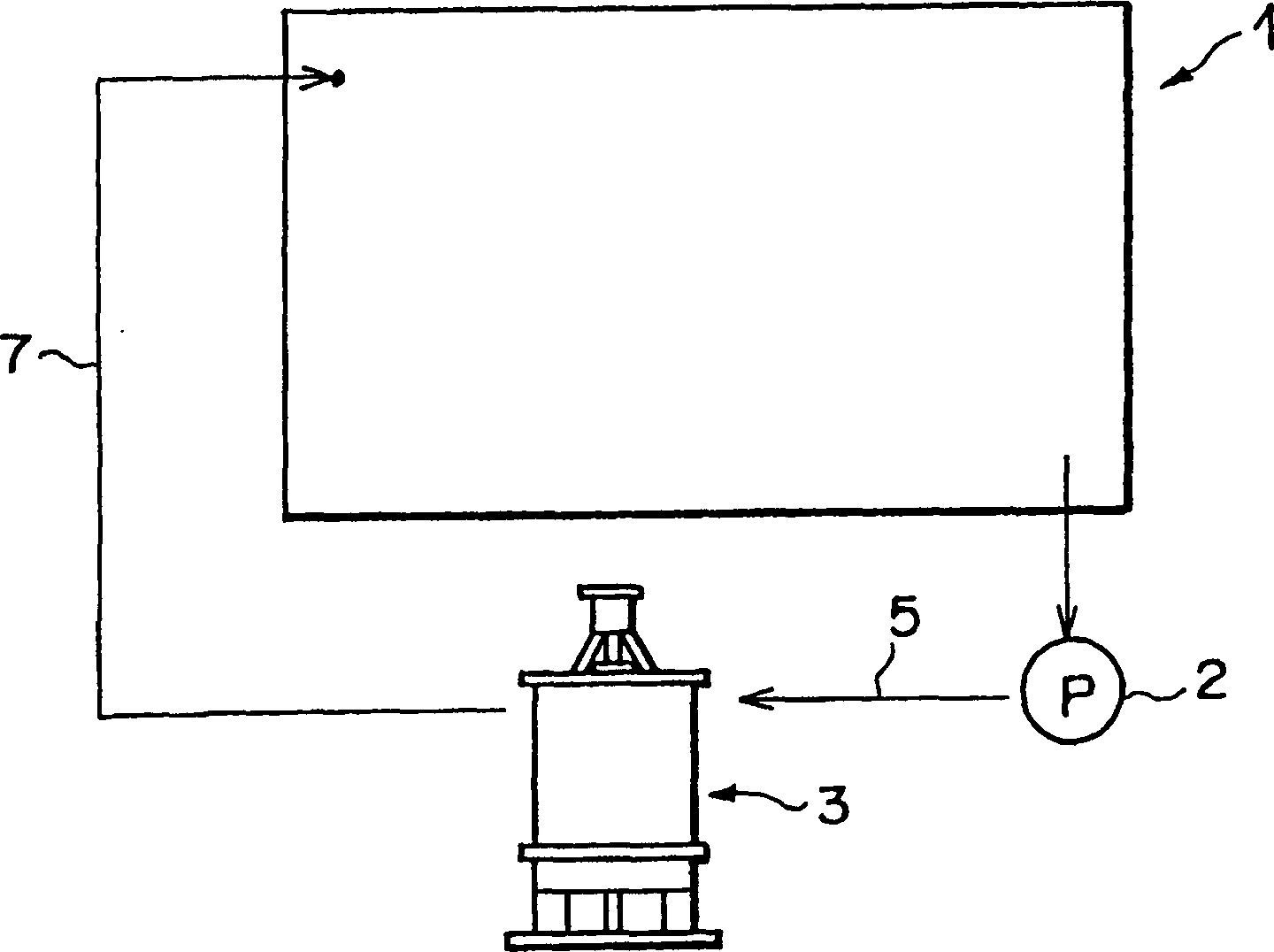

Embodiment 1

[0066] A sand washing apparatus disclosed in Japanese Unexamined Patent Publication No. Hei10-109051 comprises: a washing tank for containing sand and washing water therein; a Rotating auger; a rotating mechanism for rotating the auger at such a speed that, at the lower portion of the auger below the surface of the wash water, the rotation of the auger causes sand and cleaning water is raised while removing contaminants from the sand by contact between the sand particles and the cleaning water therebetween, and the rotation of the screw conveyor causes the sand to flow while passing a small amount of load between the sand particles and between them. Contaminants are removed from the sand by contact with contaminated water; a circulation mechanism is used as a sand washing device 3, which is used to cause the raised sand to be lowered to the lower part of the screw conveyor, and thereby to regenerate the sand Raised, thereby realizing the friction cleaning method. Such as fig...

Embodiment 2

[0070] Cleaning of filter sand was performed in the same manner as in Embodiment 1 above, except that a conventional water-jet sand cleaning device was used instead of the specific sand cleaning device. As shown in Table 4, although there was a slight difference between Example 1 and Example 2 using the specific sand cleaning equipment, the contaminated sand was significantly cleaned. In the case of Example 1, there was hardly any change in the effective particle diameter. However, in Example 2, since the cleaning was performed for a long time, the effective particle diameter decreased and the uniformity coefficient increased. It should be understood that in a conventional sand cleaning device using water jets, the sand collides with pipes, walls, etc. during cleaning, resulting in damage to the pipes, walls, etc.

[0071] polluted sand

After cleaning (minutes)

10

20

30

60

Pollution (degree)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com