Dual temperature unit heat exchange station

A heat exchange station and temperature technology, applied in the field of dual temperature unit heat exchange station, can solve the problems of project failure, high requirements for installation workers, lack of blue-collar technical personnel, etc., to achieve reliable installation quality and shorten the installation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

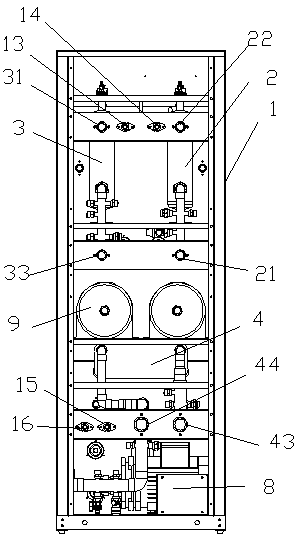

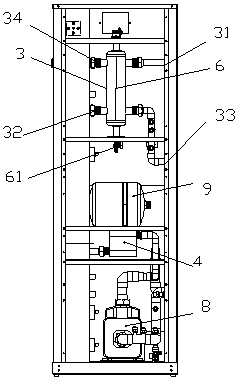

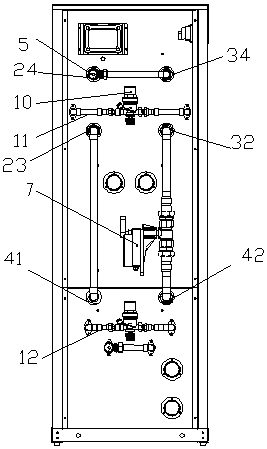

[0018] As shown in the accompanying drawings, the dual-temperature unit heat exchange station includes a frame 1, a first water mixing tank 2, a second water mixing tank 3 and a primary water inlet 41, a primary water outlet 42, a secondary water inlet 43, The plate heat exchanger 4 of the secondary water outlet 44, the first mixing tank has a cold and heat source water inlet 21, the fan outlet 22, the heat exchanger outlet 23 and the first bypass port 24, the second mixing tank 3. It has a fan return port 31, a heat exchanger return port 32, a cold and heat source outlet 33, and a second bypass port 34. The heat exchanger outlet 23 communicates with the primary water inlet 41 of the plate heat exchanger 4 through a pipeline. , the primary water outlet 42 of the plate heat exchanger 4 communicates with the return water port 32 of the heat exchanger thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com