Rotary air preheater heat transfer corrugated plate with interrupted holes and processing method for rotary air preheater heat transfer corrugated plate

A technology of air preheater and rotary type, which is applied in the field of heat transfer corrugated plate of rotary air preheater and its processing field, which can solve the problems of large flow resistance of corrugated plate and low heat transfer characteristics of corrugated plate, so as to reduce steel consumption volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

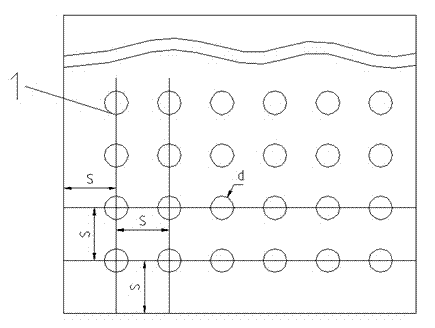

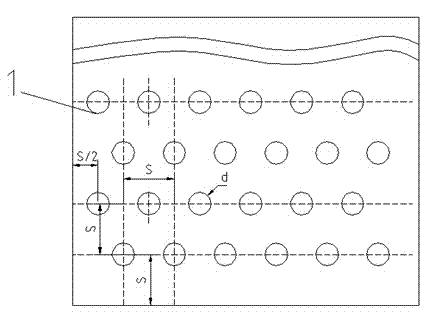

[0024] In order to illustrate the heat transfer and flow characteristics of the heat transfer corrugated plate of the rotary air preheater with spoiler holes, a specific example is given below: the heat transfer corrugated plate of the rotary air preheater with spoiler holes is composed of the first The positioning plate and the second positioning plate are stacked alternately. The unit wavelength of the second positioning plate is 16mm, the amplitude of the unit wave is 1.6mm, and the thickness of the corrugated plate is 0.5mm. The first positioning plate is formed by connecting cutouts and corrugations. The unit length is 6 mm, the wave amplitude is 4.5 mm, the unit wave length of the corrugation is 16 mm, the wave amplitude of the unit wave is 1.6 mm, and the thickness of the first positioning plate is 0.5 mm. The upper spoiler holes have a diameter of 8mm and a pitch of 20mm, arranged in a row.

[0025] Compared with the heat transfer corrugated plate of the rotary air pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com