An image-based device and method for measuring railway snow depth

A measurement method and image technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of short measurement distance, false alarm, low precision, etc., and achieve the effects of fast measurement speed, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

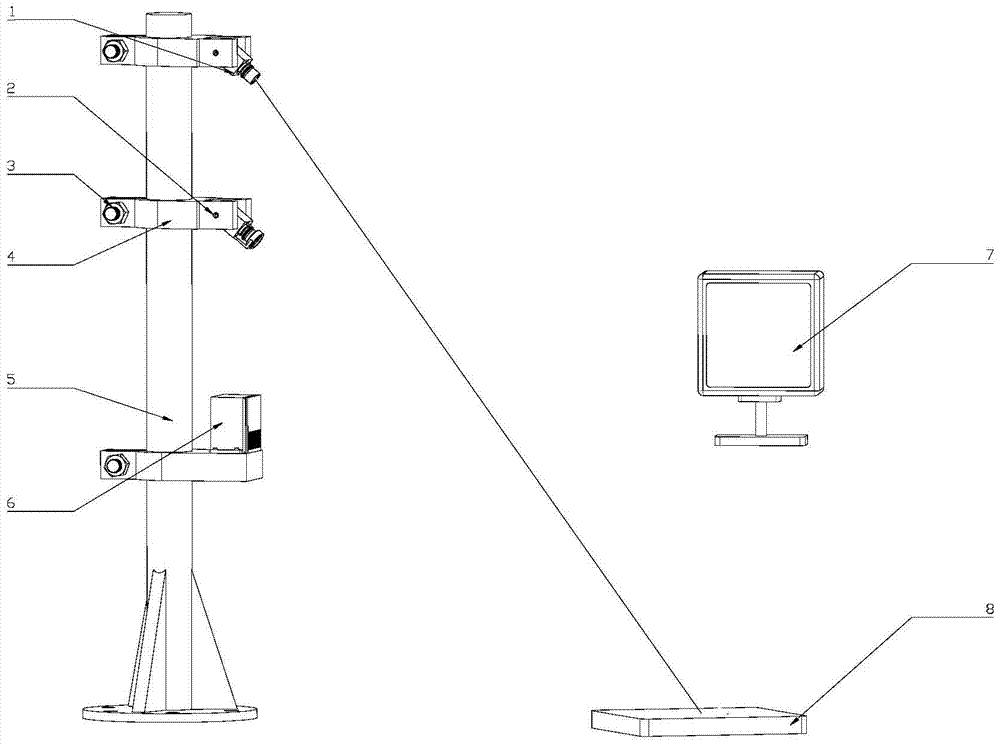

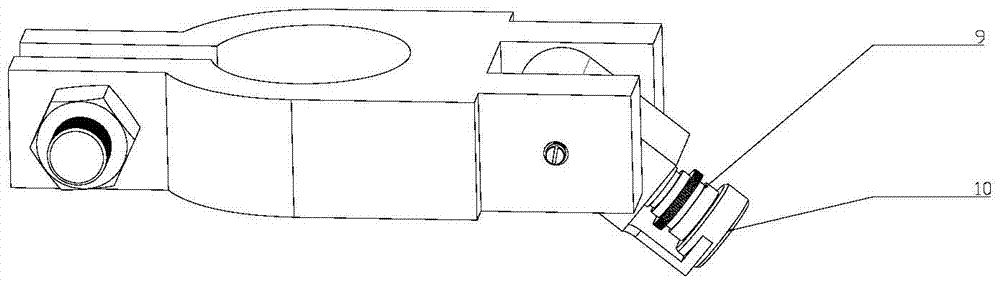

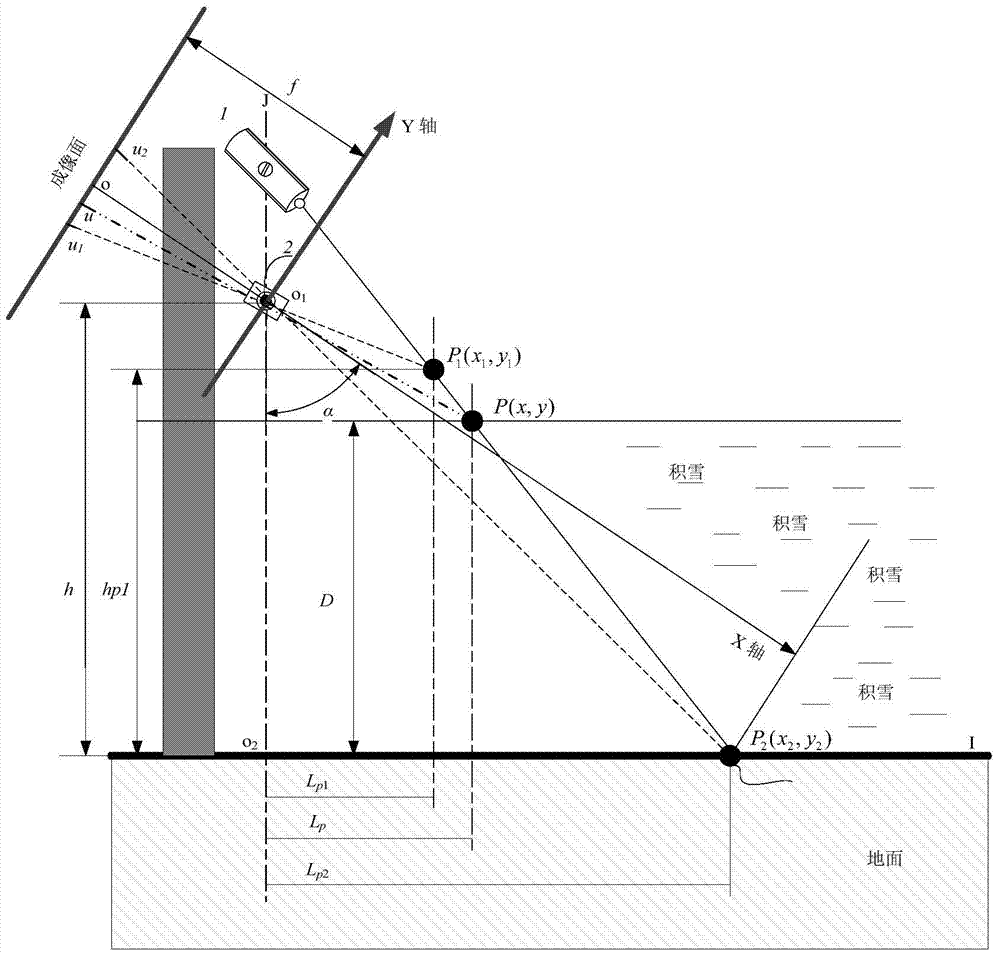

[0022] combine Figure 1~2 , the image-based railway snow depth measurement device of the present invention is characterized in that it includes a laser probe 1, a bracket 5, a data processing platform 6, a network camera 9, an infrared bandpass filter 10, a terminal computer 7, and a ground reference board 8; The support 5 is vertically installed with the ground, and the ground reference plate 8 is parallel to the ground; wherein the laser probe 1, the network camera 9, and the data processing platform 6 are respectively arranged on the support 5 through the fixing frame 4 from top to bottom, and the laser probe 1 , network camera 9, and data processing platform 6 are respectively fixed on the fixed frame 4 of corresponding position by screw 2, and three fixed frames 4 are horizontally fastened on the support 5 by bolt 3 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com