Axis deviation detection device and detection method

A detection device and detection method technology, applied in the direction of measuring devices, instruments, etc., can solve problems that are difficult to meet the needs of actual production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

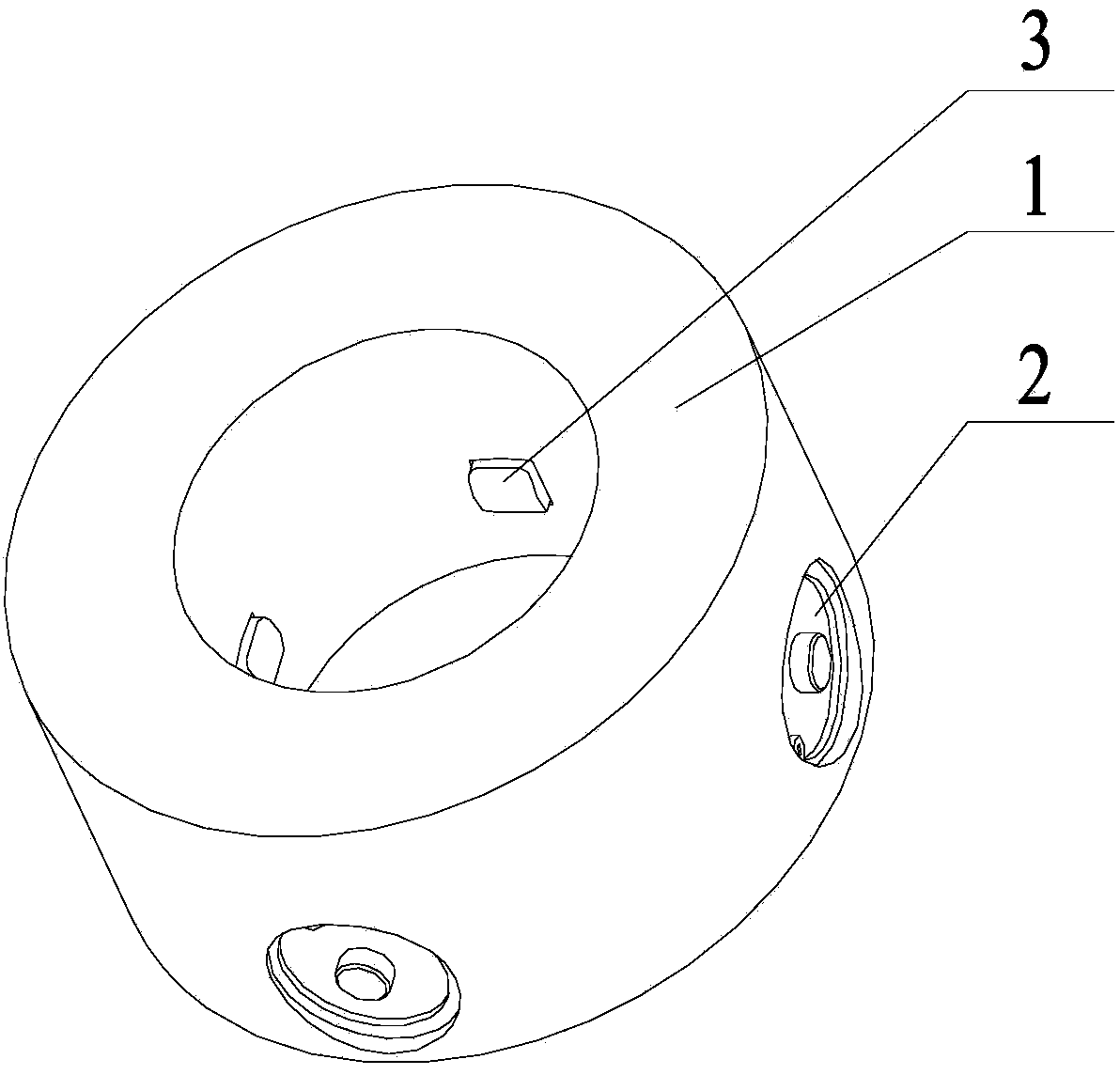

[0076] See attached figure 1 , the shaft deflection detection device provided by the present invention includes a positioning ring 1 and a detection head 2, a plurality of through holes are provided in the radial direction on the side wall of the positioning ring 1, the number of the detection heads 2 is the same as the number of the through holes, and the detection head 2 are arranged in the through hole in a one-to-one correspondence, the inner probe 3 of each detection head 2 is cocircular and coincides with the center of the positioning ring, and the inner probe of each detection head can move in the through hole.

[0077] When the shaft deflection detection device provided by the present invention is applied, the shaft to be measured passes through the center of the positioning ring 1, and each detection head 2 is moved so that the inner measuring head 3 of each detection head 2 is against the shaft to be measured. According to this The displacement of the internal measur...

Embodiment 2

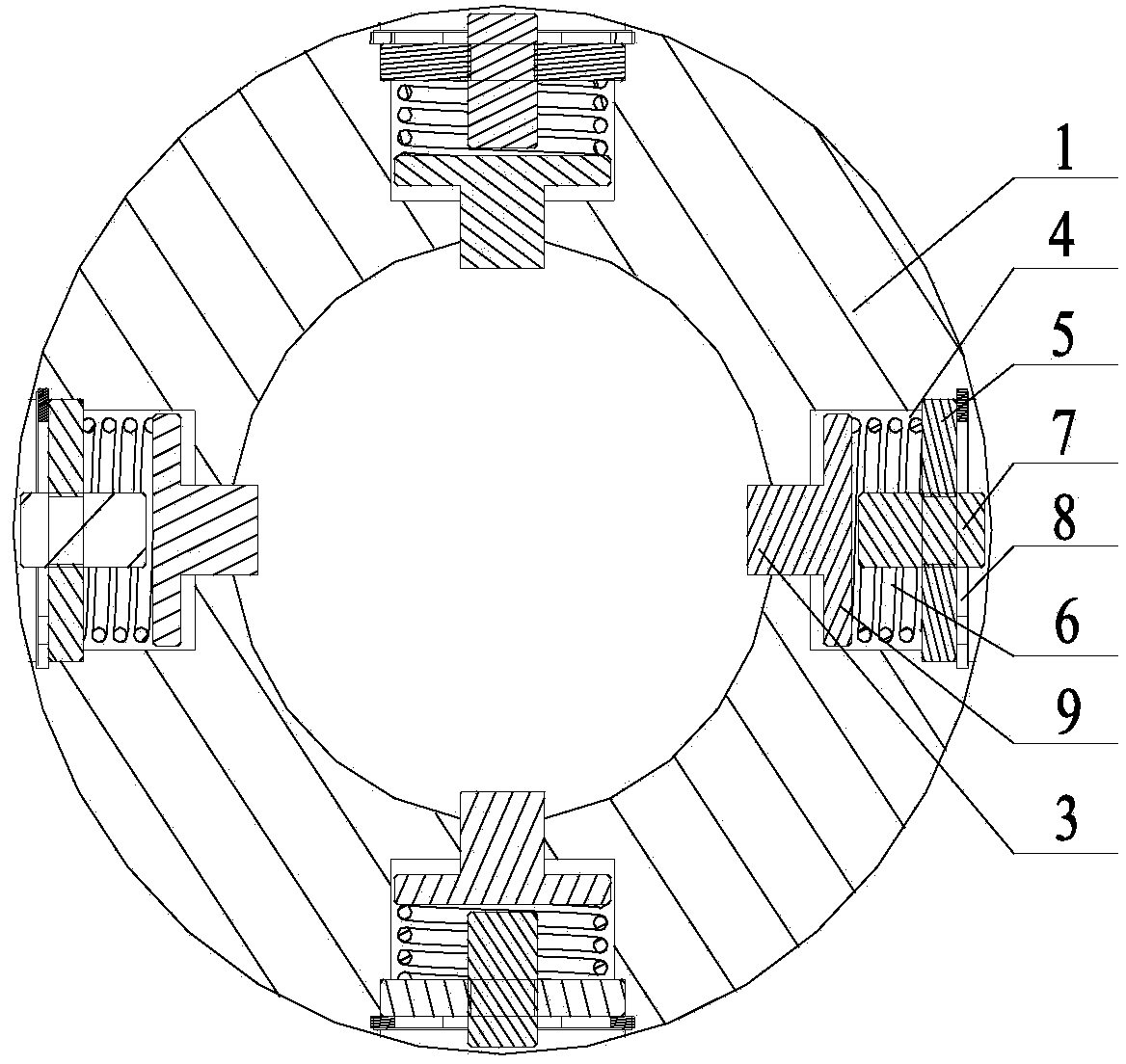

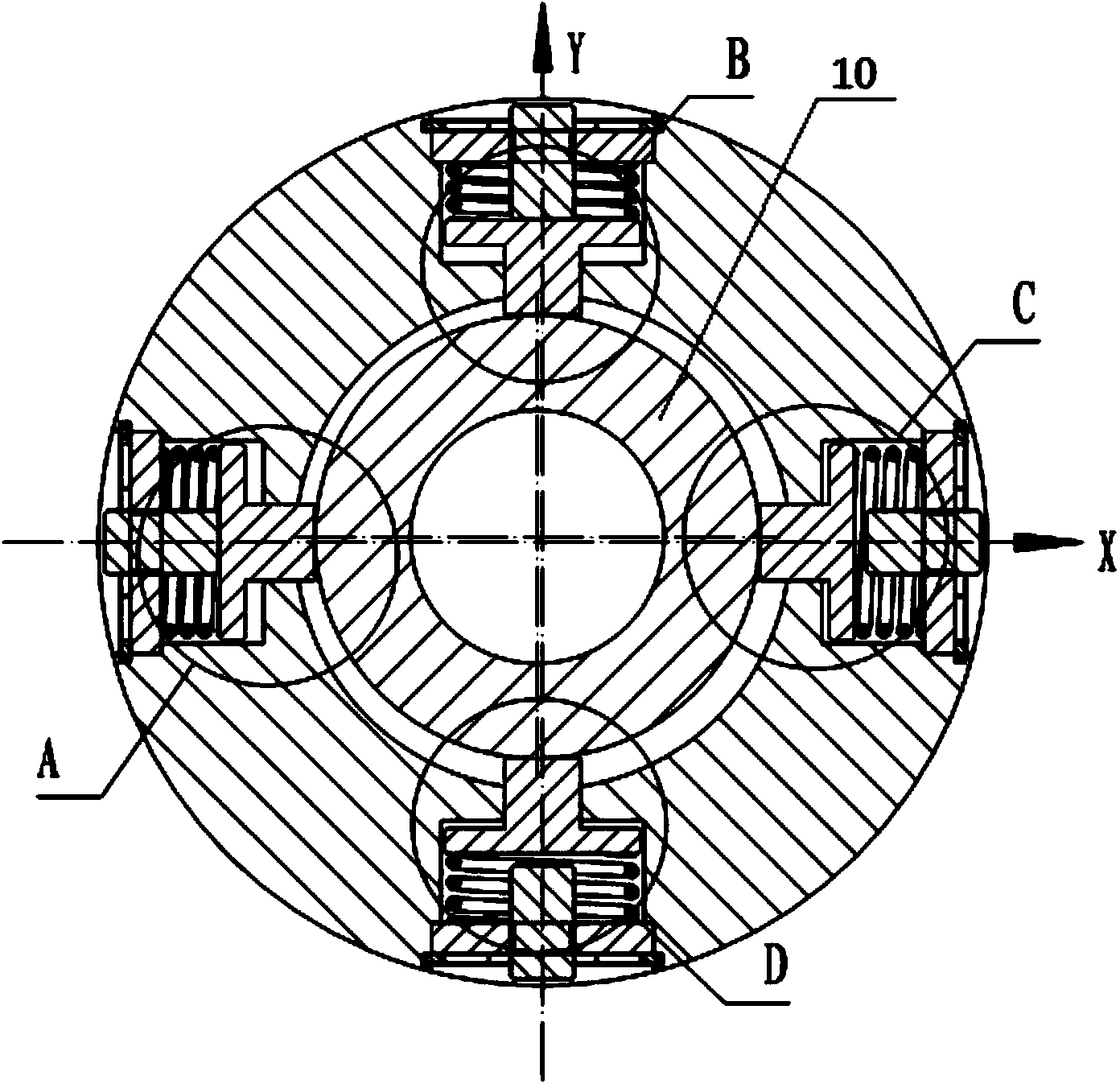

[0081] See attached Figure 2-7 , the difference from Embodiment 1 of the present invention is that the through hole of the shaft deflection detection device provided in Embodiment 2 of the present invention is a stepped hole, and the stepped hole includes three sections from the outside to the inside and the diameters are successively reduced. The detection head includes Gasket 5, column 7, elastic part 4, pressing piece 9 and internal measuring head 3, the diameter of gasket 5 is equal to the diameter of the through hole of the first section, the diameter of pressing piece 9 is equal to the diameter of the through hole of the second section, the column 7 Fixedly connected to the gasket 5, the inner diameter of the elastic part 4 is larger than the diameter of the column 7, the outer diameter of the elastic part 4 is smaller than the diameter of the second section of the through hole, the diameter of the internal measuring head 3 is equal to the diameter of the third section o...

Embodiment 3

[0084] See attached Figure 21 , the difference from the shaft deflection detection device provided in Embodiment 2 of the present invention is that the shaft deflection detection device provided in Embodiment 3 of the present invention further includes a data acquisition module, a data operation module and a data output module,

[0085] The data acquisition module is used to collect the displacement value of the internal measuring head of each detecting head;

[0086] The data operation module is used to calculate the abscissa and ordinate of the center of the axis to be measured deviated from the center of the positioning ring according to the displacement of the inner probe of each detection head;

[0087] The data output module is used to output the abscissa and ordinate of the center of the shaft to be measured deviated from the center of the positioning ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com