Mother board, mother board after box pairing, corresponding manufacturing method and liquid crystal display panel

A motherboard and substrate substrate technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve problems such as low transmittance, inability to check to confirm alignment accuracy, difficult to cut accurately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementations of the motherboard provided by the embodiments of the present invention, the motherboard after the box, the corresponding manufacturing method, and the liquid crystal display panel will be described in detail below in conjunction with the accompanying drawings.

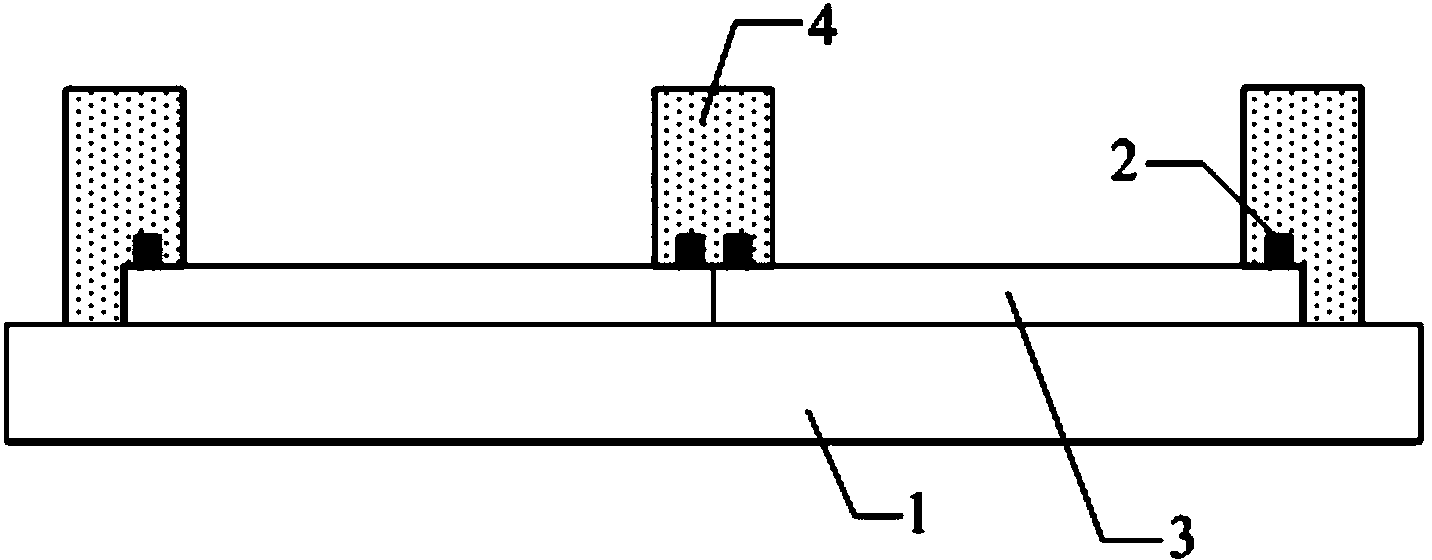

[0045] The shape and thickness of each film layer in the drawings do not reflect the true ratio of the array substrate or the counter substrate, and are only intended to illustrate the content of the present invention.

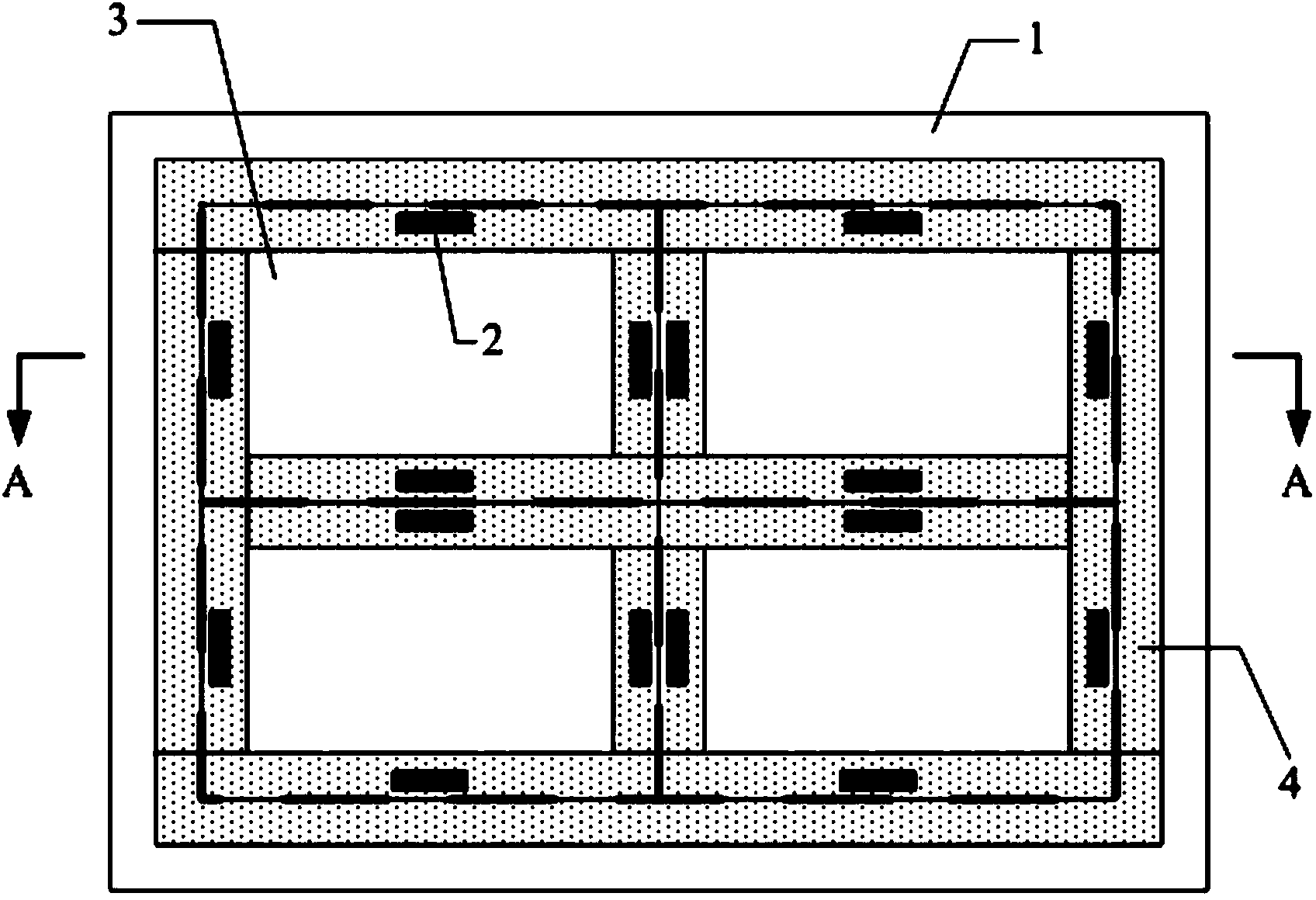

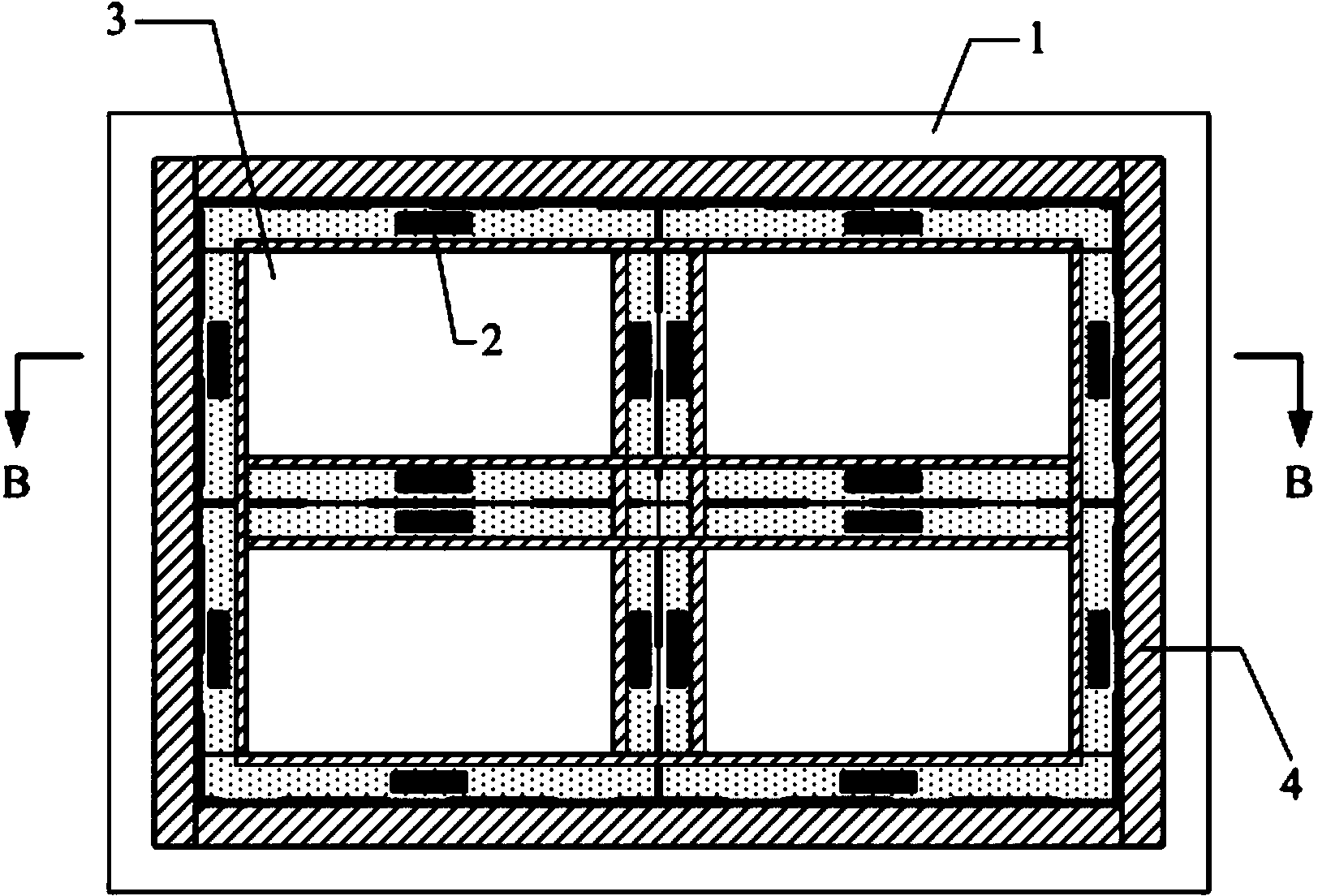

[0046] A motherboard provided by an embodiment of the present invention, such as Figure 1a , Figure 1b , Figure 2a with Figure 2b Shown, where, Figure 2a for Figure 1a A cross-sectional view along the AA direction, Figure 2b for Figure 1b A cross-sectional view along the BB direction, including: a base substrate 1 and a plurality of substrate units 3 with alignment marks 2 arranged in a matrix on the base substrate 1 ( Figure 1a with Figure 1b Take the substrate uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com