Method and system for detecting symmetry of printed matter

A technology for symmetry detection and printing, applied in image analysis, image enhancement, instruments, etc., can solve the problems of inaccurate printing, real-time detection and control, etc., and achieve strong robustness, improve detection efficiency and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution, and work flow of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

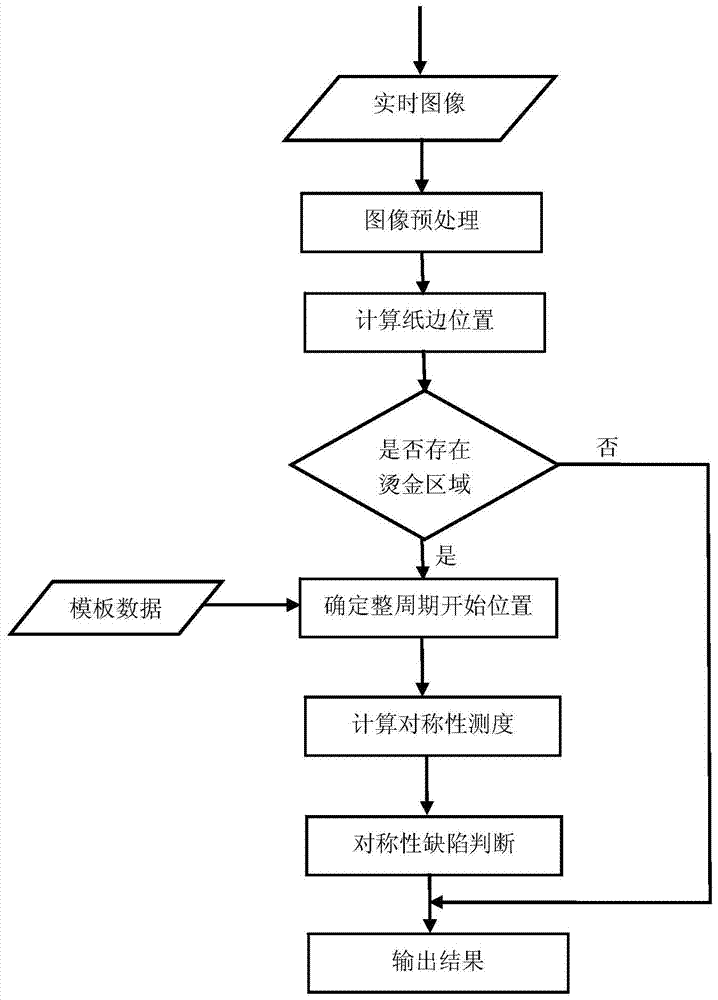

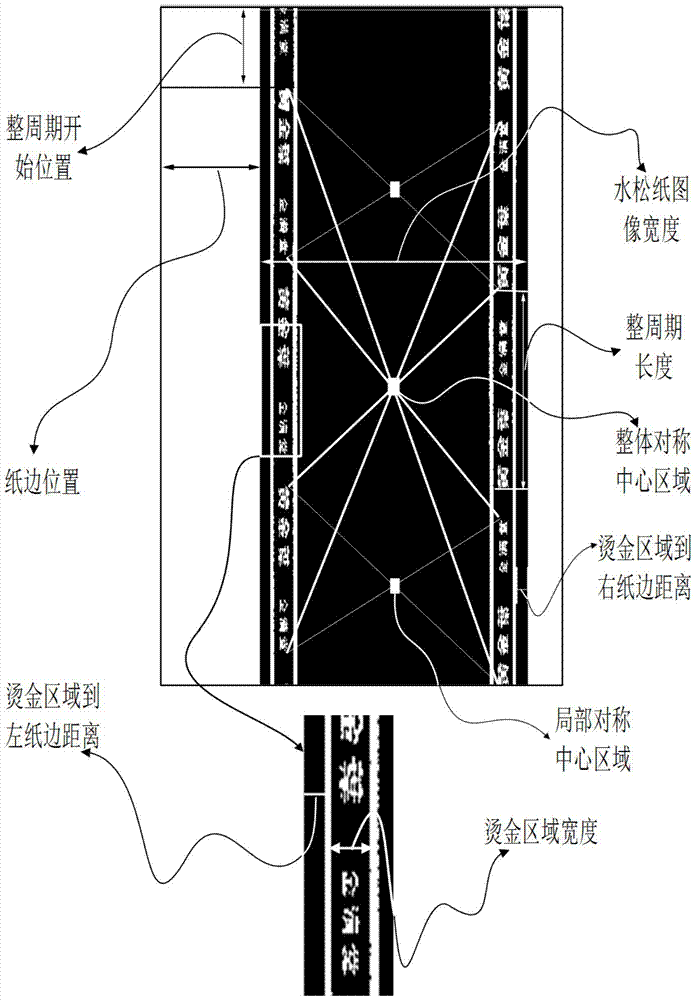

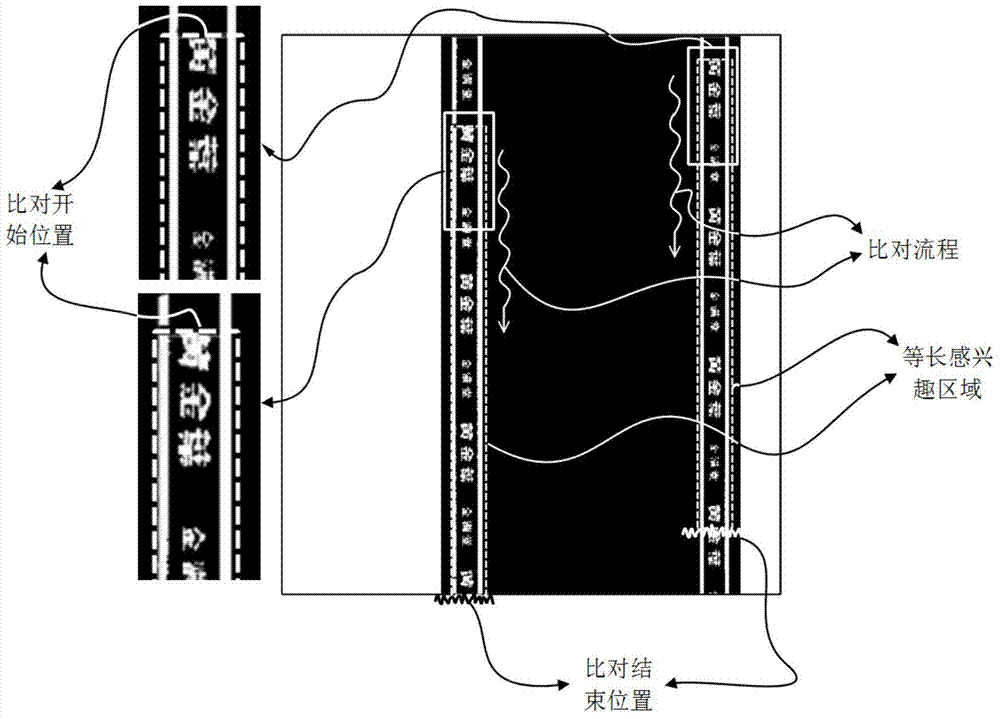

[0050] The method provided by the invention can adopt computer software technology to realize the automatic operation process. In this embodiment, the tipping paper overprinting hot stamping logo is taken as an example for illustration, and other types of paper and logos are processed in the same manner during specific implementation. Such as figure 1 As shown, the embodiment uses the tipping paper image data to process the specific implementation process as follows:

[0051] Step 1. Real-time image preprocessing: grayscale processing is performed on the image of the printed matter to be inspected obtained in real time to obtain a grayscale image. Subsequent steps are performed based on the grayscaled real-time image. Obtaining printed matter ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com