Buffer units for elevators

A buffer unit and elevator technology, which is applied to elevators in buildings, lifting equipment in mines, elevators, etc., can solve the problems of expensive structure, heavy weight, large footprint, etc., and achieve the effect of small structure height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

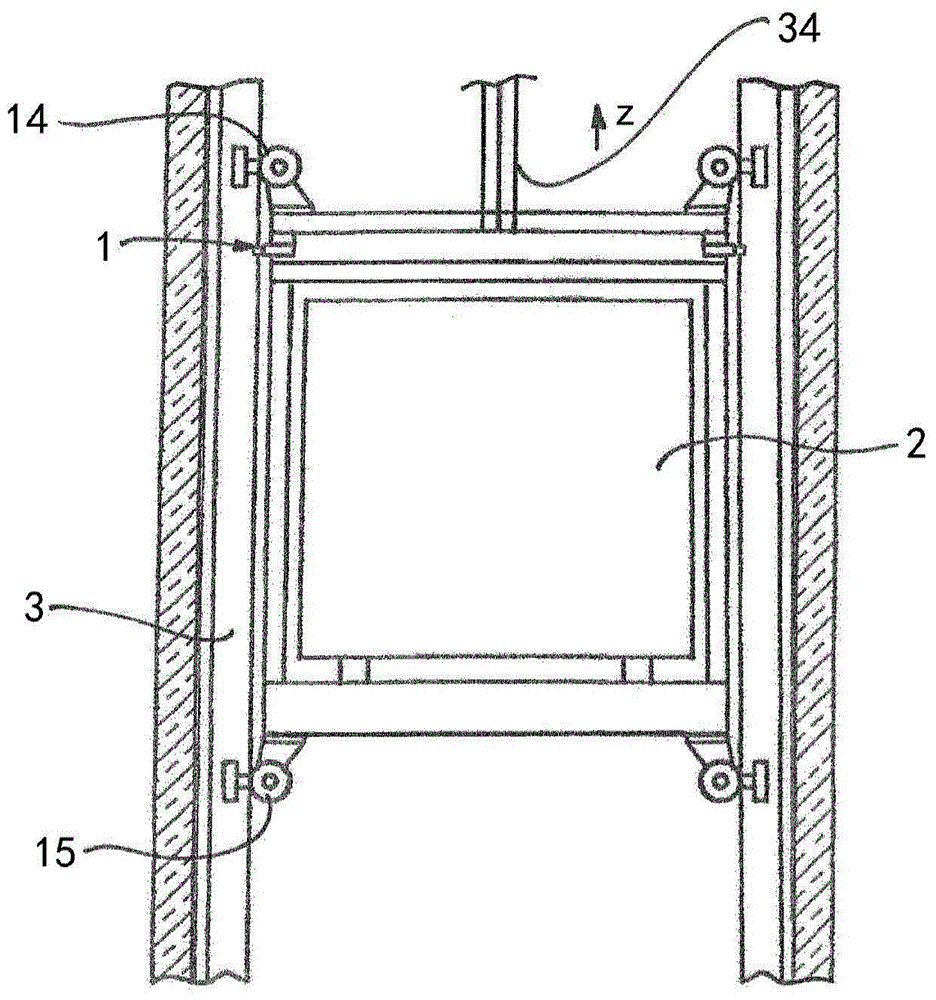

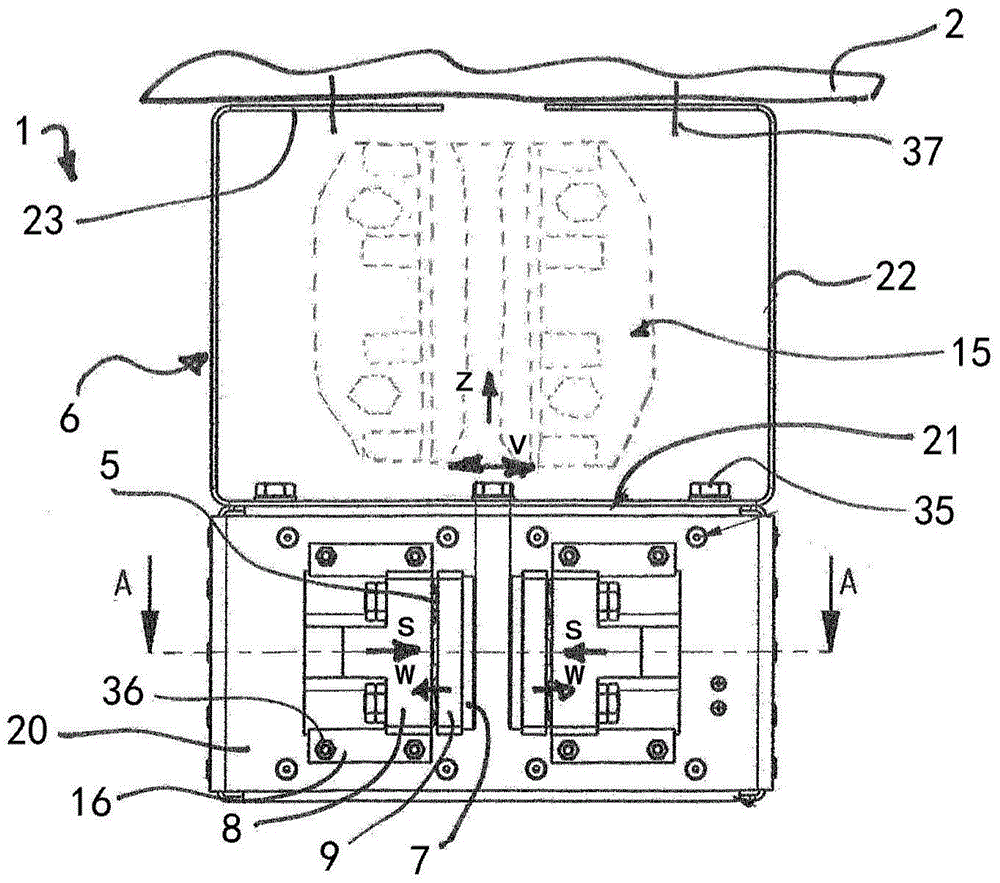

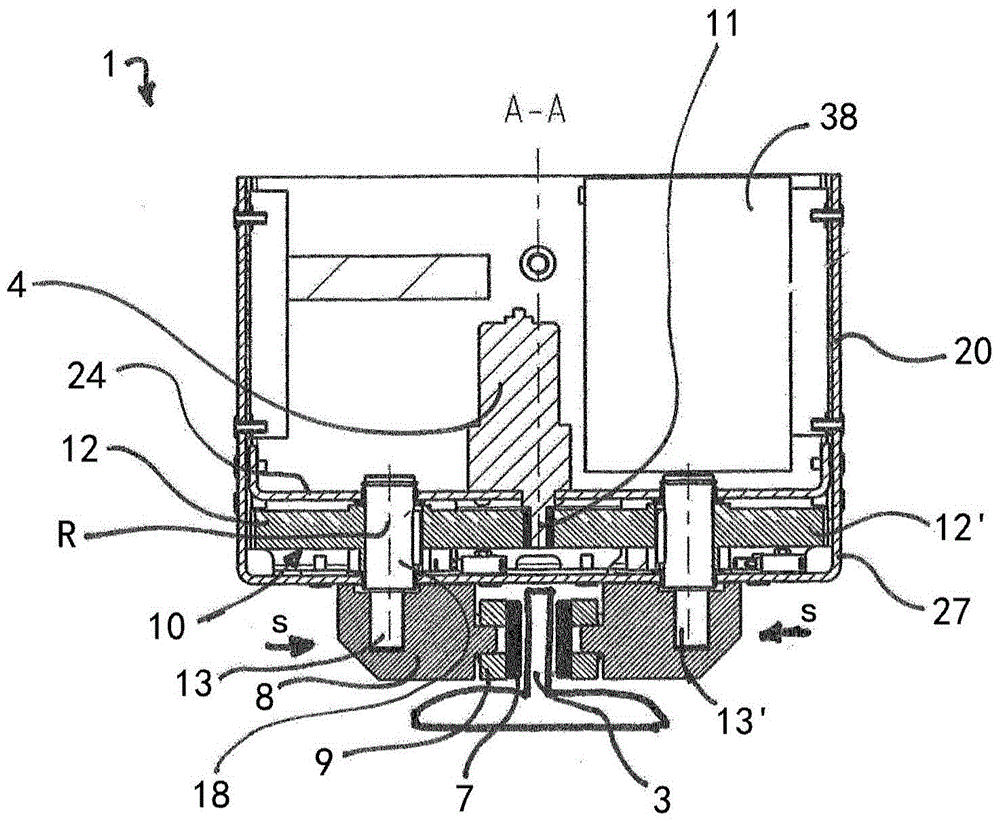

[0030] figure 1 An elevator with a car 2 for transporting people or goods that can move vertically up and down is shown. For example, a carrying mechanism 34 configured as a belt or a rope is used as the carrying mechanism for moving the car 2. In order to guide the car 2, the elevator installation has two guide rails 3 extending in the vertical running direction z. Here, each guide rail 3 has three guide surfaces extending in the traveling direction of the car. Installed on the car 2 figure 1 The guide shoe is configured as a roller guide shoe by way of example. With the buffer unit marked with 1, the undesired vertical vibration of the car can be reduced during parking. Such vertical vibration is generated when a person steps on or leaves the car 2. The car 2 is stuck in vibration due to the load change. This phenomenon is particularly evident in elevators with high shaft heights based on load-bearing belts. The direction in which the guide rail extends is indicated by z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com