Ink composition for coated steel sheet

A technology for coating steel plates and compositions, applied in the directions of inks, applications, household appliances, etc., can solve problems such as reduced adhesion, lifting or peeling, etc.

Inactive Publication Date: 2015-02-04

SAKURA COLOR PRODUCTS CORPORATION

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there has been a problem in the past: when there is a marking layer formed of an ink composition between the upper and lower coating films applied to the surface of the steel sheet, there is a certain relationship between the coating film and the components

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

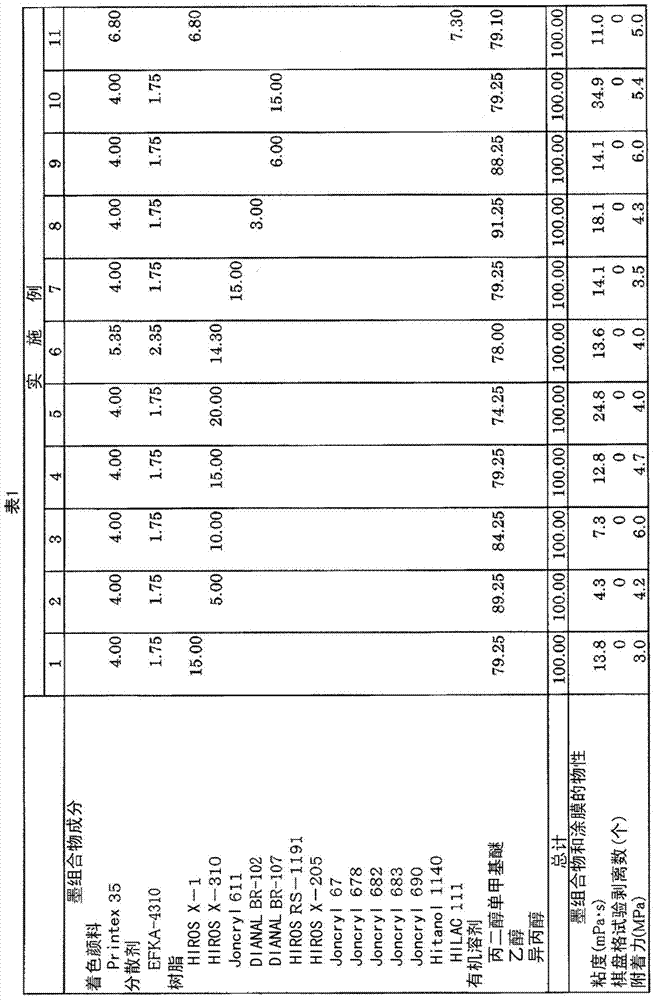

[0073] Using the components shown in Table 1 in the amounts shown in Table 1, ink compositions were prepared as described above.

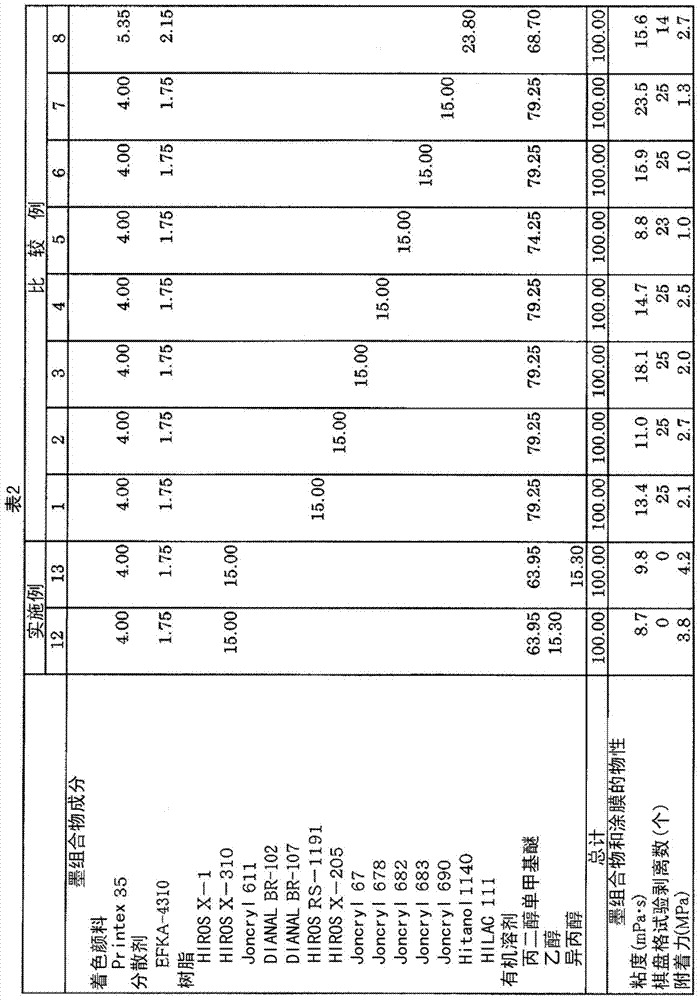

Embodiment 2~13

[0075] Using the components shown in Table 1 and Table 2 in the amounts shown in Table 1 and Table 2, ink compositions were prepared as described above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

[Problem] To provide an ink composition for a coated steel sheet, whereby, when a marking layer produced from the ink composition is provided between two coating layers (i.e., an upper coating layer and a lower coating layer) each formed from a coating agent and provided on the surface of a steel sheet, it becomes possible to prevent the deterioration of adhesion force of the two coating layers at the marking position and therefore it becomes possible to provide such a marking that the upper coating layer cannot come from the lower coating layer at the marking position or the upper coating layer cannot be delaminated from the lower coating layer at the marking position. (Solution) The present invention provides an ink composition for a coated steel sheet, which comprises an organic solvent, a pigment, a dispersant and a resin, said ink composition being characterized in that the resin comprises an acrylic resin and/or a styrene-acrylic resin each having an acid value of 150 mgKOH/g or less and a glass transition temperature ranging from 0 to 55°C.

Description

technical field [0001] The present invention relates to an ink composition for coating steel plates. Specifically, the present invention relates to an ink composition for coating a steel plate, even if the upper and lower two-layer coating films formed by the coating applied to the steel plate, such as an undercoat coating film and a top coating film, have the ink composition between them. The formed marking layer will not cause the reduction of the adhesion between the two coating films, so the above-mentioned upper coating film will not lift or peel off at the marking position. Background technique [0002] For example, in the manufacture of large-scale structures such as shipbuilding, bridges, pressure vessels, and chemical reagent containers using thick steel plates, material storage, semi-finished product storage, and assembly are mostly carried out outdoors, and the construction period is often long, so there is no prior planning. When any surface treatment is applied...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): C09D11/00

CPCC09D11/106C09D11/037C09D11/00

Inventor 北口贵之

Owner SAKURA COLOR PRODUCTS CORPORATION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap