Tank for liquid-filled transformers or inductors

A technology of transformers and inductors, which is applied in the direction of transformer/inductor housing, transformer/inductor cooling, transformer/inductor components, etc., and can solve the problem that the sound insulation of transformers and inductors cannot be satisfactorily solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

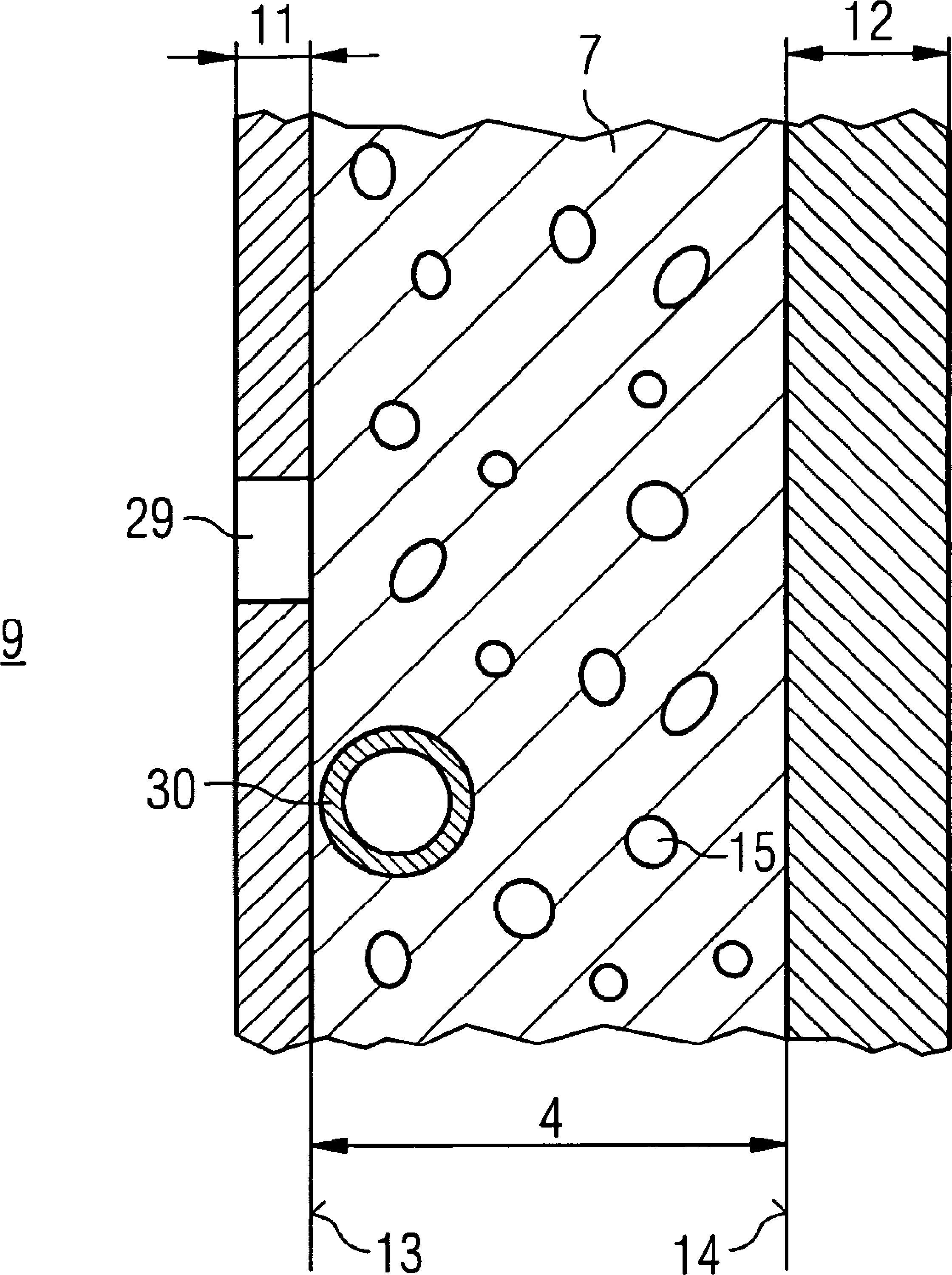

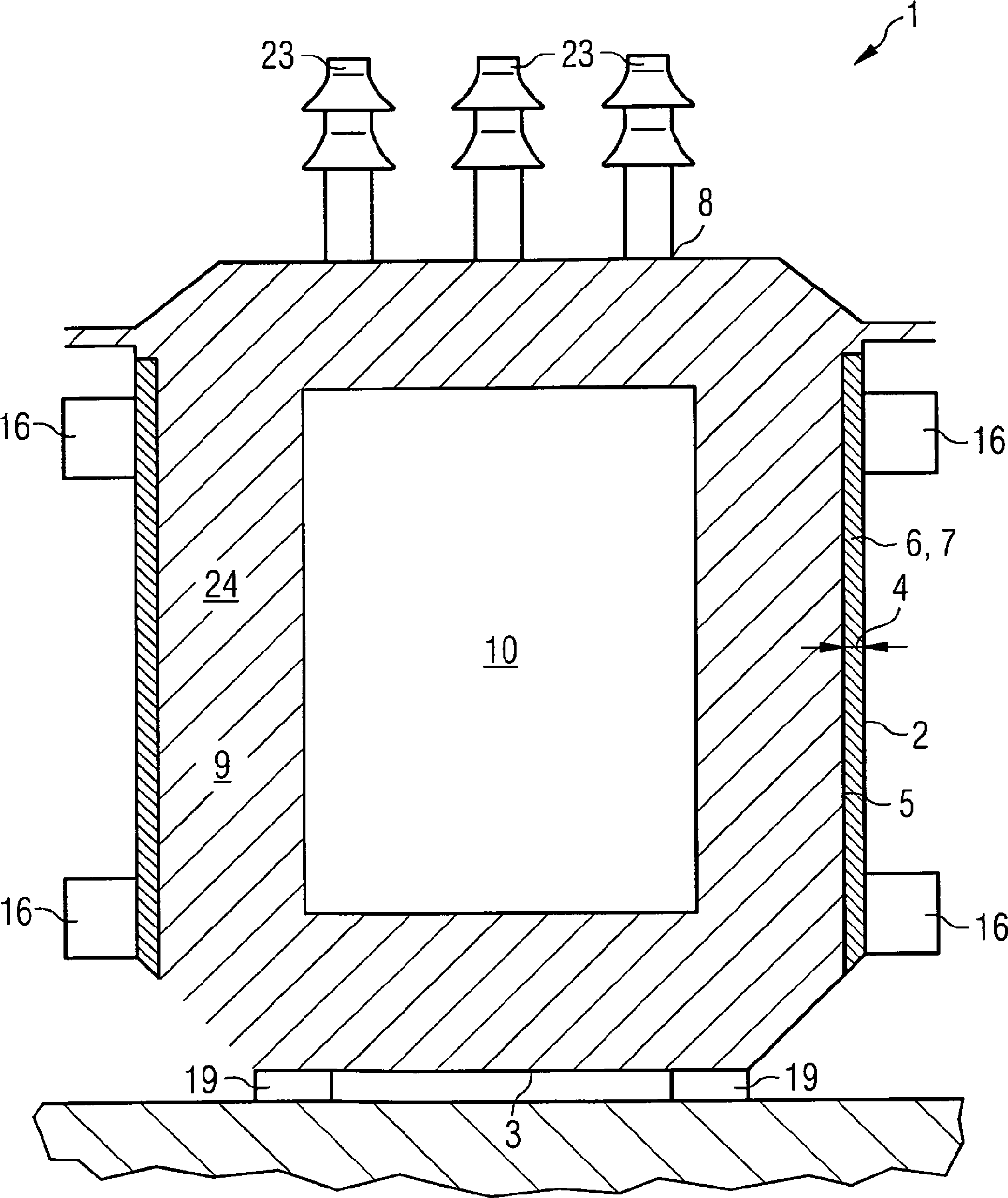

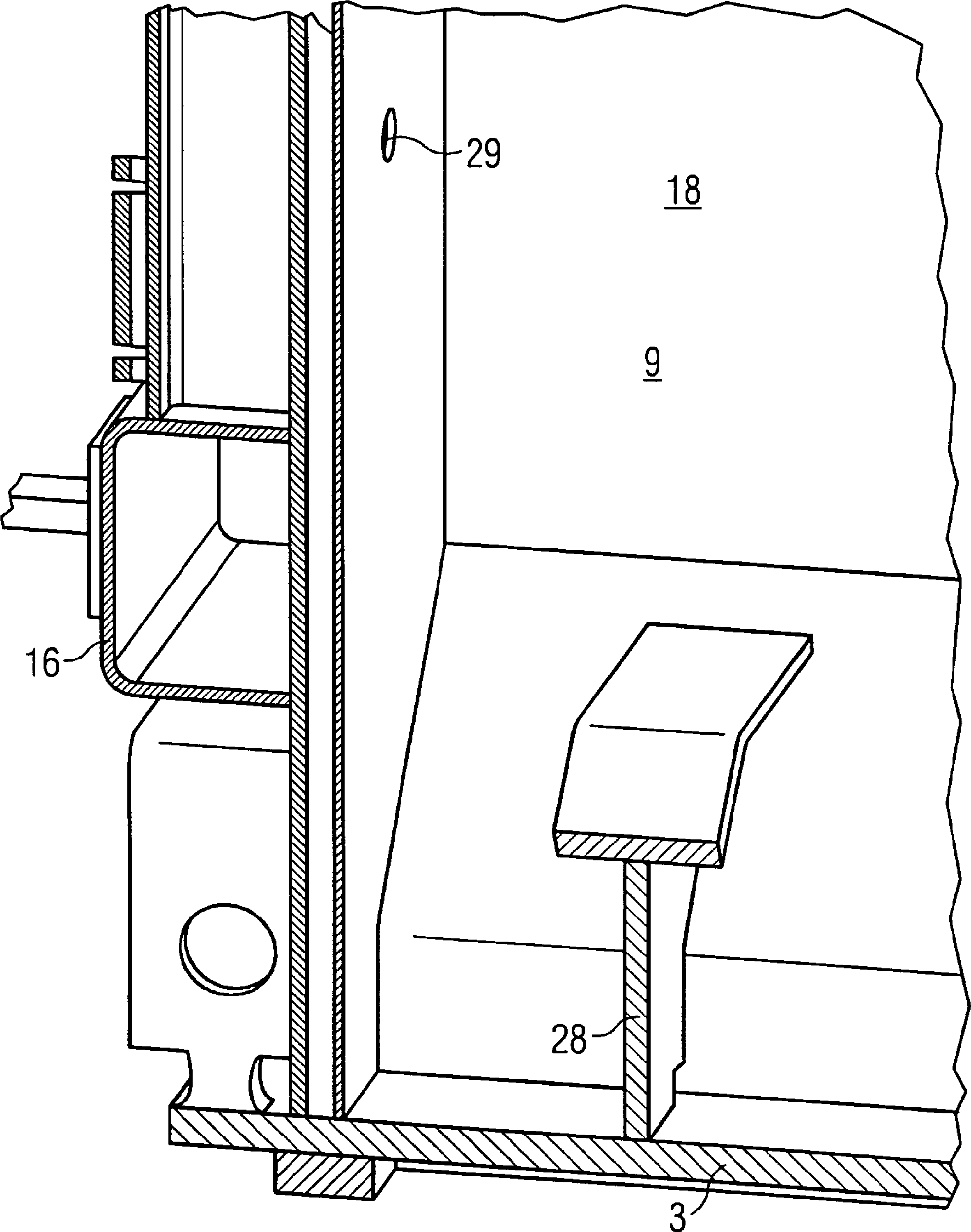

[0036] figure 1 Tank 1 is shown, the shell of which is designed in the manner of a double-wall tank. The two double walls 2 , 5 are formed by an outer tank shell 2 and an inner tank shell 5 , which are arranged at a distance 4 from one another. Between the two shells 2 , 5 there is a circumferential gap 6 which is filled according to the invention with a plastic or polymer material 7 . The outer shell 2 tapers downwards to a bottom surface portion 3 . The bottom part 3 is supported on elastic supports 19 on a base. An electrical connection 23 (Durchführungen (penetration)) is arranged on the cover 8 . Before the transformer / inductor is put into operation, a negative pressure is normally generated in the inner chamber 9 . In order to ensure the mechanical stability of the tank under vacuum, different reinforcements are installed on the tank in the interior as well as in the field, among which, the figure 1 For the sake of overview, only the reinforcements 16 arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com