Method for preparing flexible conductive film by coating copper nanoparticles with citrate

A technology of copper nanoparticles and citrate, applied in the field of microelectronics, can solve problems such as poor bending stability, achieve enhanced conductivity, simple and easy preparation method, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

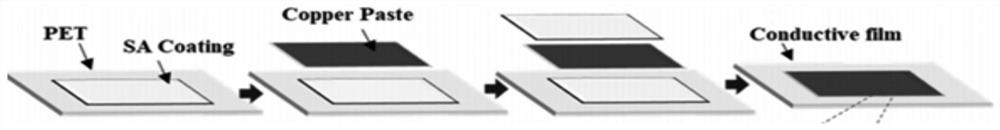

[0035] The method provided by the invention adopts citrate-coated copper nanoparticles to prepare a flexible conductive film, comprising the following steps:

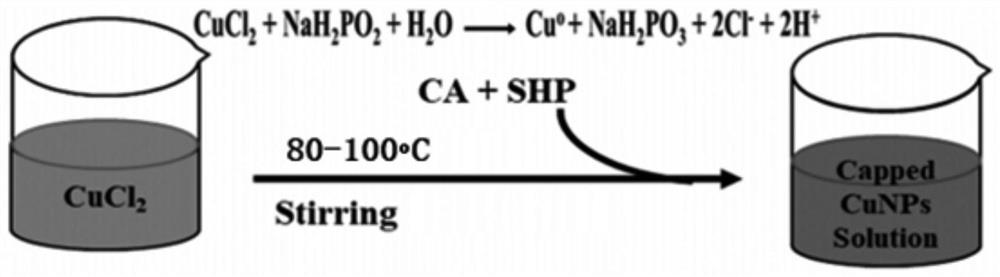

[0036] 1) Synthesis of citrate-coated copper nanoparticles—copper nanoparticles (CuNPs) were synthesized by a wet chemical reduction method, and the specific steps are as follows:

[0037] 1.1) Dissolving 50 mmol of copper chloride in 20 ml of water, raising the temperature of the reaction mixture to 90° C., stirring continuously at a speed of 1200 rpm, and keeping the temperature and speed constant throughout the synthesis reaction process;

[0038] Add 0.96 mg of citric acid (CA) to the reaction mixture solution, then add 0.76 mg of low sodium phosphate monohydrate (NaH 2 PO 2 .H 2 O, SHP), the reaction mixture was stirred at the same constant temperature for 15min until the reaction was complete. The complete judgment standard was: first observe that the reaction color changed from greenish blue to greenish blue in...

Embodiment 2

[0047] The method provided by the invention adopts citrate-coated copper nanoparticles to prepare a flexible conductive film, comprising the following steps:

[0048] 1) Synthesis of citrate-coated copper nanoparticles—copper nanoparticles (CuNPs) were synthesized by a wet chemical reduction method, and the specific steps are as follows:

[0049] 1.1) 50 mmol of copper chloride was dissolved in 20 ml of water, and the temperature of the reaction mixture was raised to 80° C., continuously stirred at a speed of 1000 rpm, and the temperature and speed were kept constant throughout the synthesis reaction process;

[0050] Add 0.96 mg of citric acid (CA) to the reaction mixture solution, then add 0.66 mg of low sodium phosphate monohydrate (NaH 2 PO 2 .H 2 O, SHP), the reaction mixture was stirred at the same constant temperature for 15min until the reaction was complete. The complete judgment standard was: first observe that the reaction color changed from greenish blue to green...

Embodiment 3

[0059] The method provided by the invention adopts citrate-coated copper nanoparticles to prepare a flexible conductive film, comprising the following steps:

[0060] 1) Synthesis of citrate-coated copper nanoparticles—copper nanoparticles (CuNPs) were synthesized by a wet chemical reduction method, and the specific steps are as follows:

[0061] 1.1) Dissolving 50 mmol of copper chloride in 20 ml of water, raising the temperature of the reaction mixture to 100° C., stirring continuously at a speed of 1200 rpm, and keeping the temperature and speed constant throughout the synthesis reaction process;

[0062] Add 0.96 mg of citric acid (CA) to the reaction mixture solution, then add 0.86 mg of low sodium phosphate monohydrate (NaH 2 PO 2 .H 2 O, SHP), the reaction mixture was stirred at the same constant temperature for 15min until the reaction was complete. The complete judgment standard was: first observe that the reaction color changed from greenish blue to greenish blue i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com