Hybrid drive for water vehicle

A driving device and a hybrid technology, applied in the direction of power devices, hybrid vehicles, mechanical gear transmissions, etc., can solve the problems of complex device structure, additional equipment, high cost, etc., and achieve the effect of simplifying the structure and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

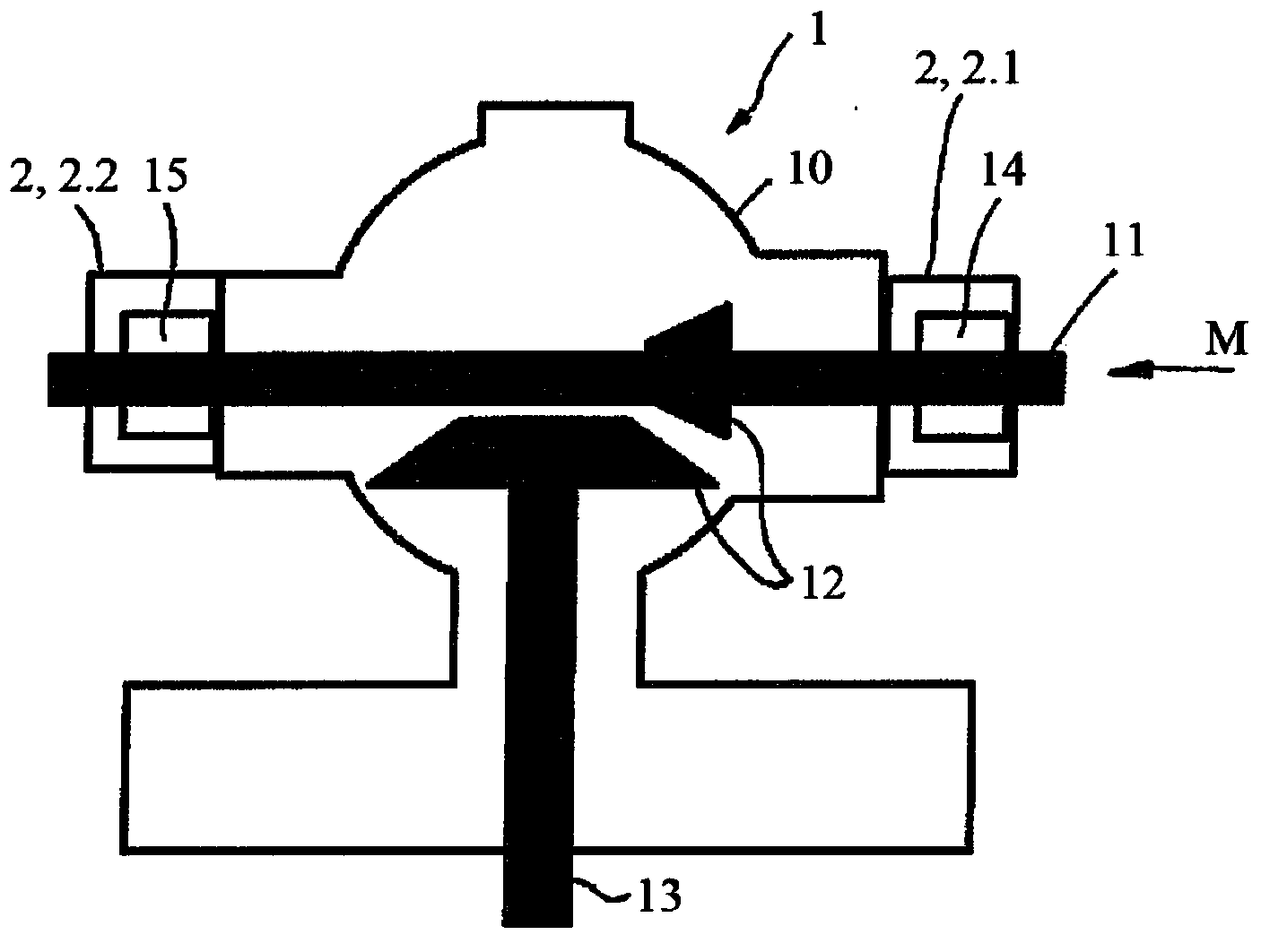

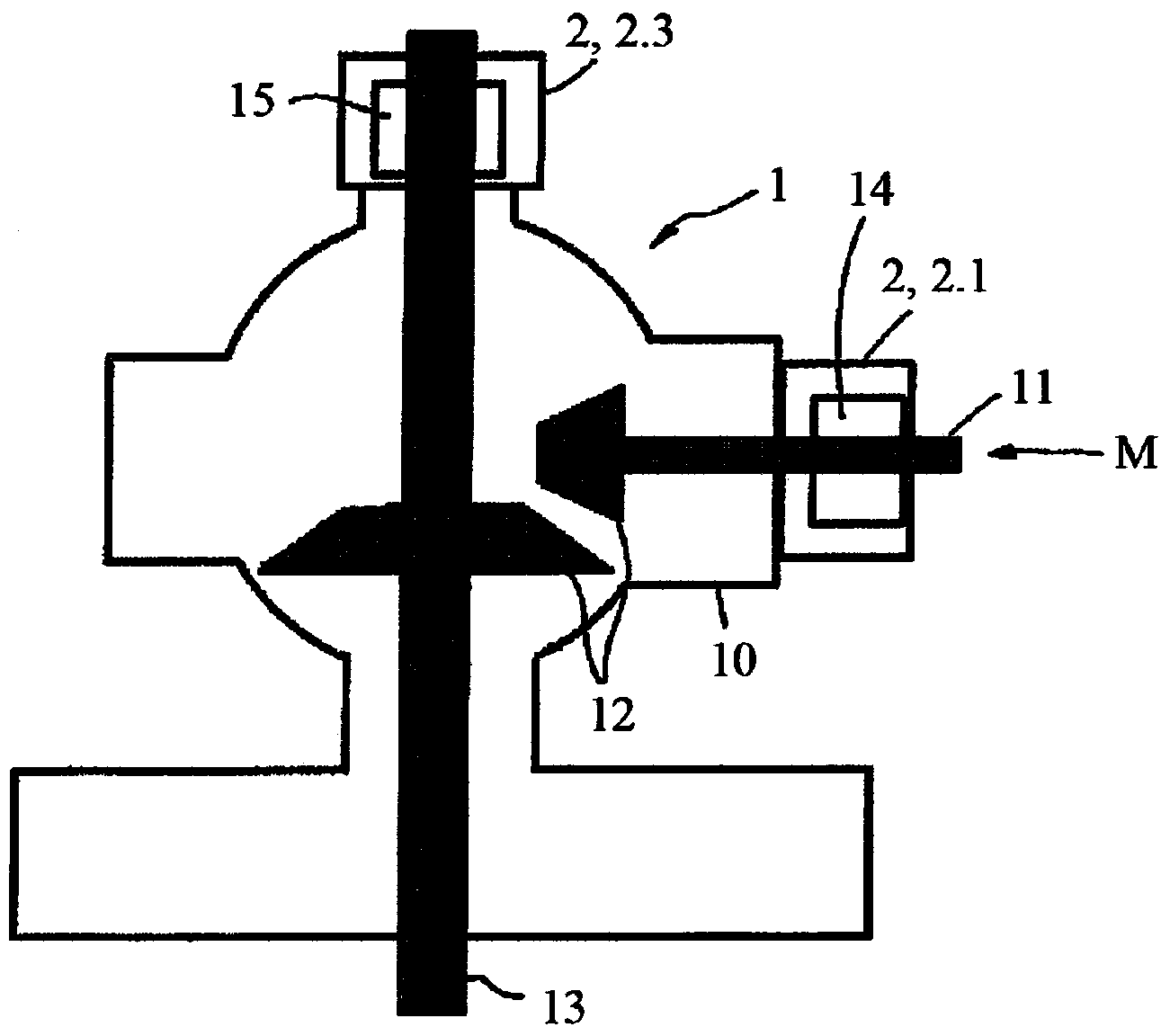

[0033] figure 1 Shows a schematic diagram of a marine transmission of a hybrid drive, wherein the marine transmission 1 comprises a drive shaft 11 extending approximately horizontally in a transmission housing 10, which is driven as an L-shaped drive via an angle transmission 12 with bevel gears A vertically extending vertical shaft 13 protrudes from the housing 10 of the marine transmission 1 . The components shown in this figure are generally arranged inside the vessel, not shown here.

[0034] The vertical shaft 13 leads in a manner not shown in detail to a rudder oar arranged on the outside of the ship, more precisely under the hull, in a conventional embodiment as shown in DE 20 2009 009 031 U1.

[0035] The drive shaft 11 is driven with power and torque M by a primary drive motor, not shown here, which is also arranged inside the vessel, for example an internal combustion engine.

[0036] The coupling to the drive shaft 11 can be established or decoupled via the coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com