Portable cotton picker

A cotton picker, portable technology, applied in the field of portable cotton pickers, can solve problems such as slowing down the speed, increasing the load, and tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings of the description.

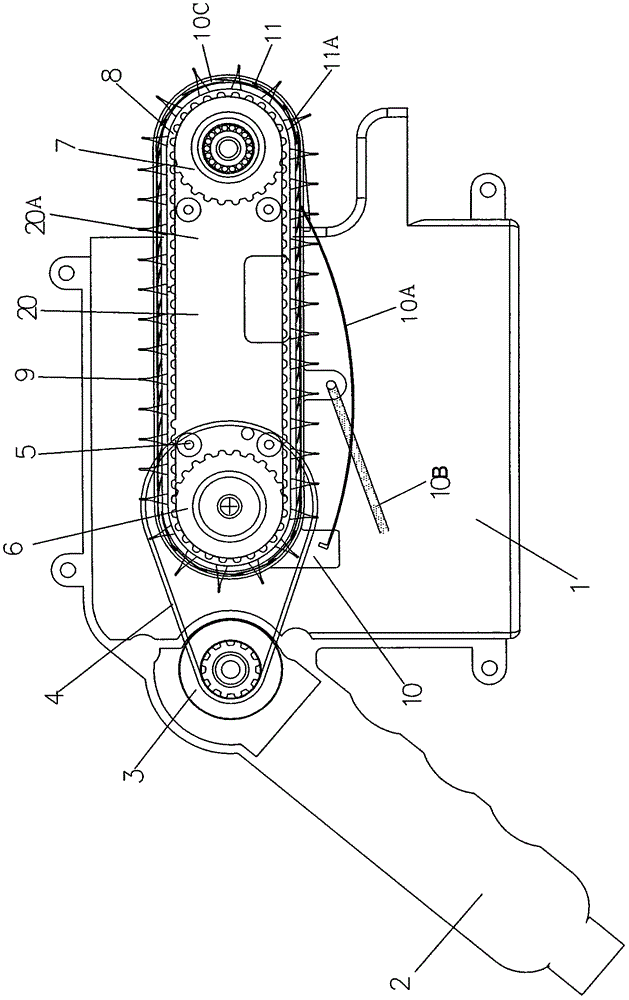

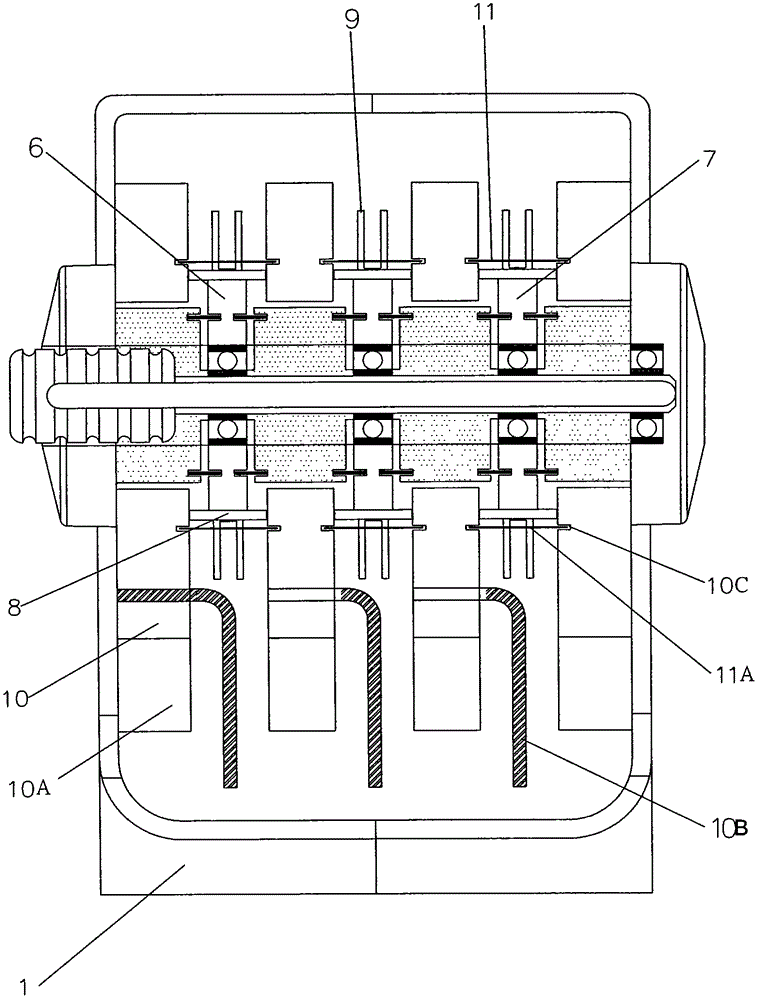

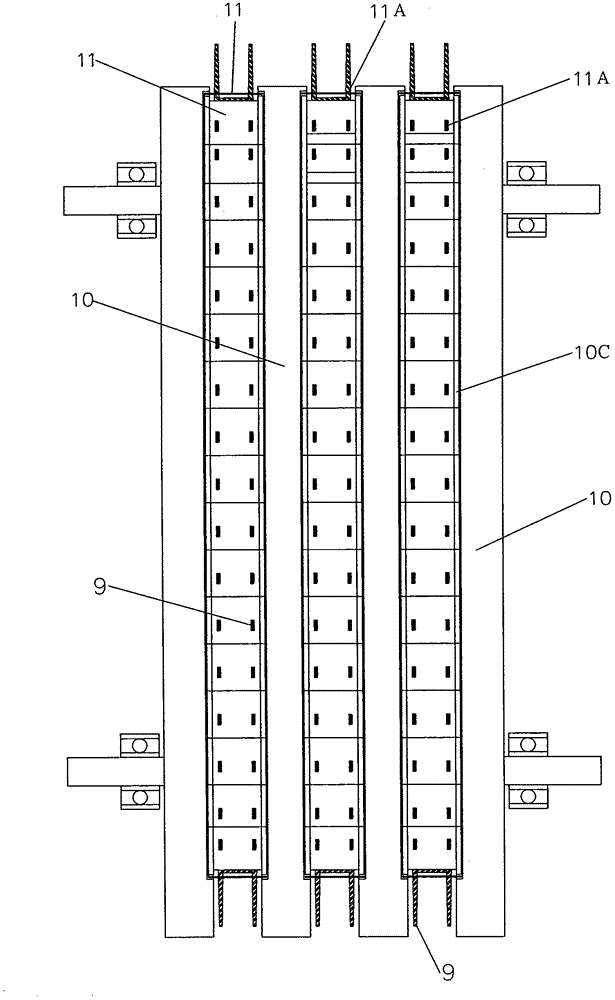

[0014] figure 1 and figure 2 It is a cross-sectional view of the embodiment of the present invention. 1. A portable cotton picker, including a left-right symmetrical shell (1) and a handle (2) installed on the shell (1). The motor (3) drives the cotton picking and picking assembly (20) through the connection of the belt (4). The cotton picking and picking assembly (20) is provided with 2 to 6 sets of cotton unloading blocking plates (10) arranged in parallel. The cotton unloading blocking plate (10) and the cotton unloading blocking plate (10) are arranged and fixed in parallel and transversely symmetrically by the positioning of the limit post (5), and the cotton unloading blocking plate (10) and the cotton unloading blocking plate (10) can be left in the middle. The active cotton picking conveyor pulley (6) and the driven cotton picking conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com