Cartridge case detection device

A detection device and cartridge casing technology, which is applied in transportation and packaging, conveyor objects, sorting, etc., can solve problems such as inability to stir, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

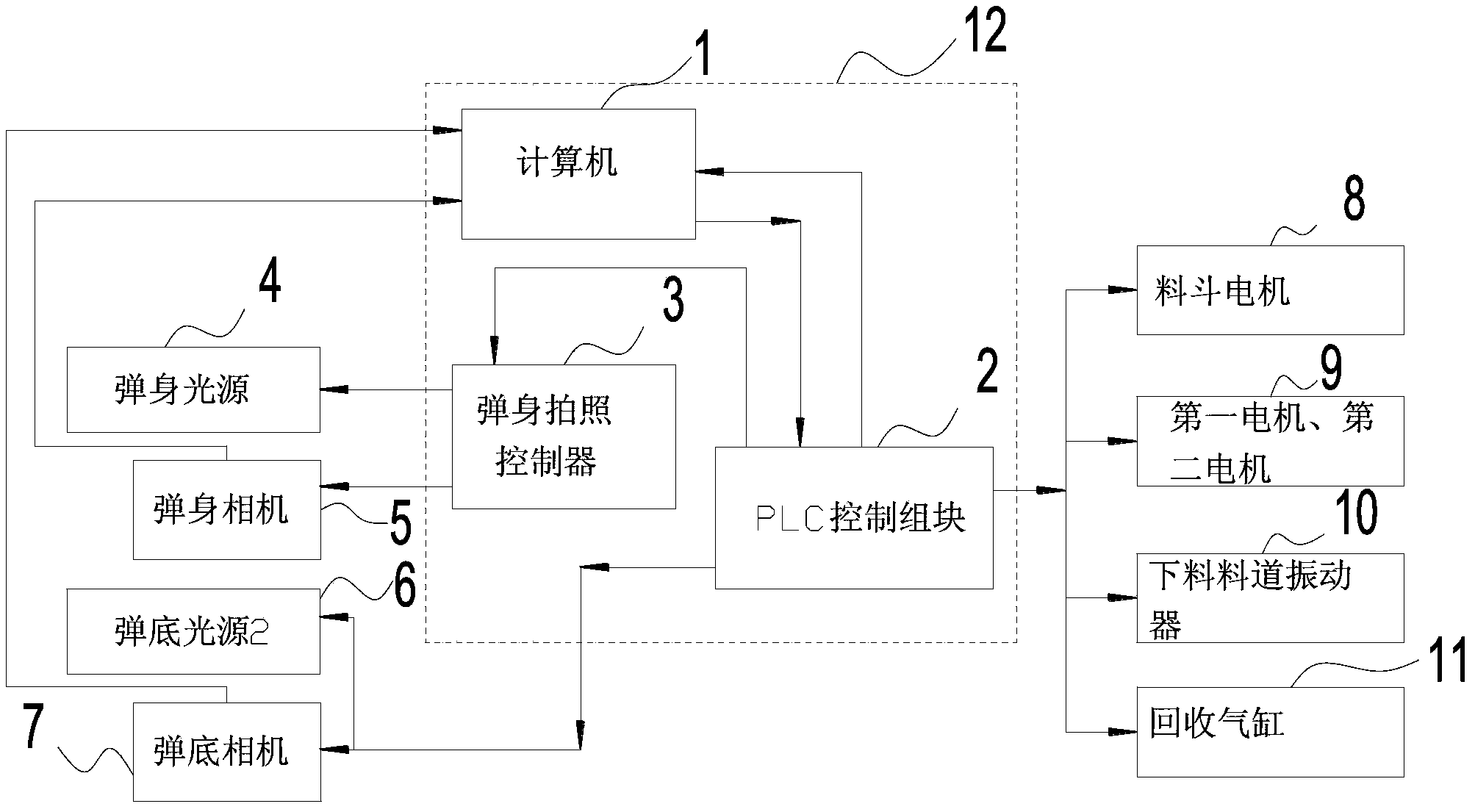

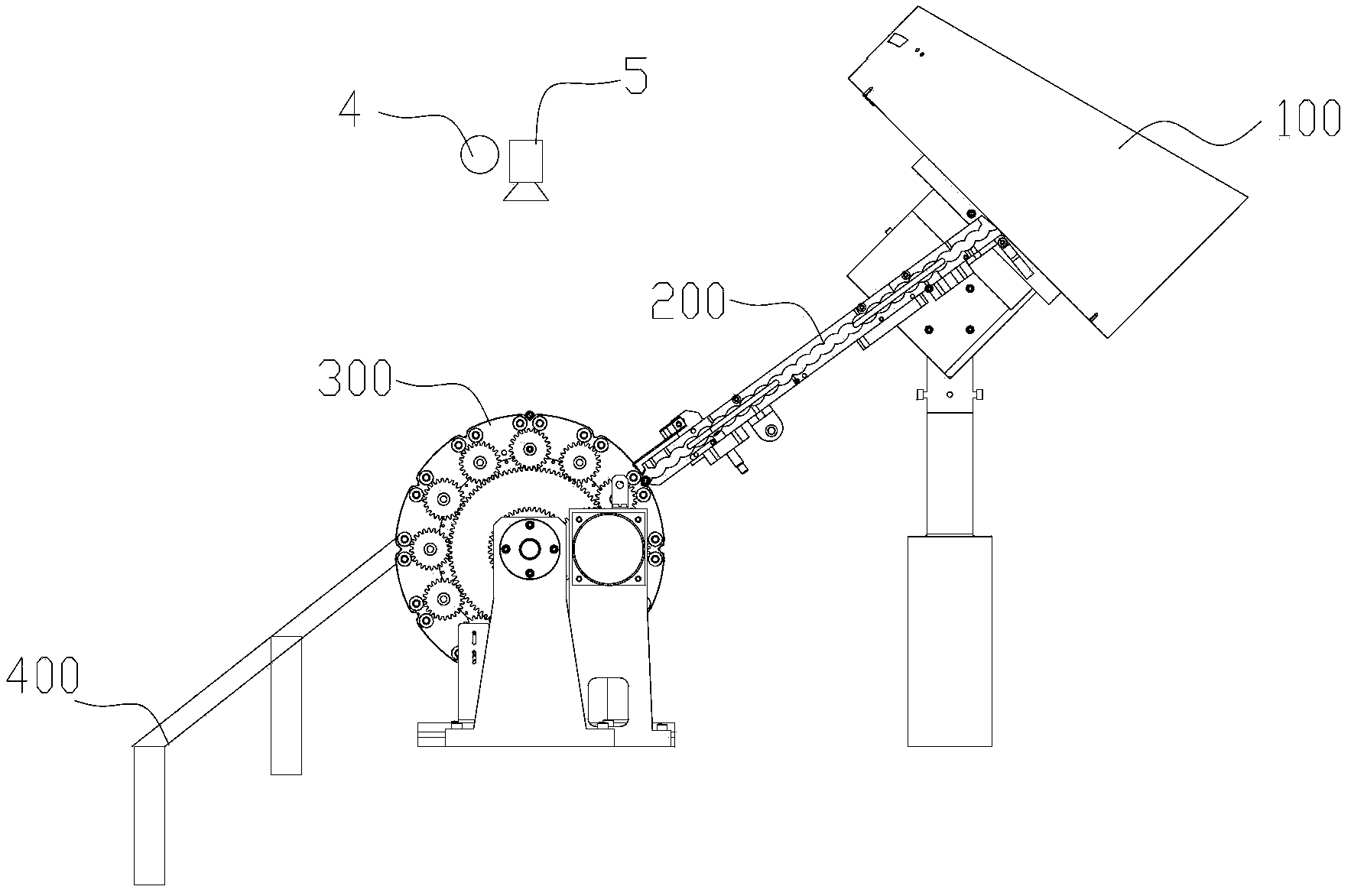

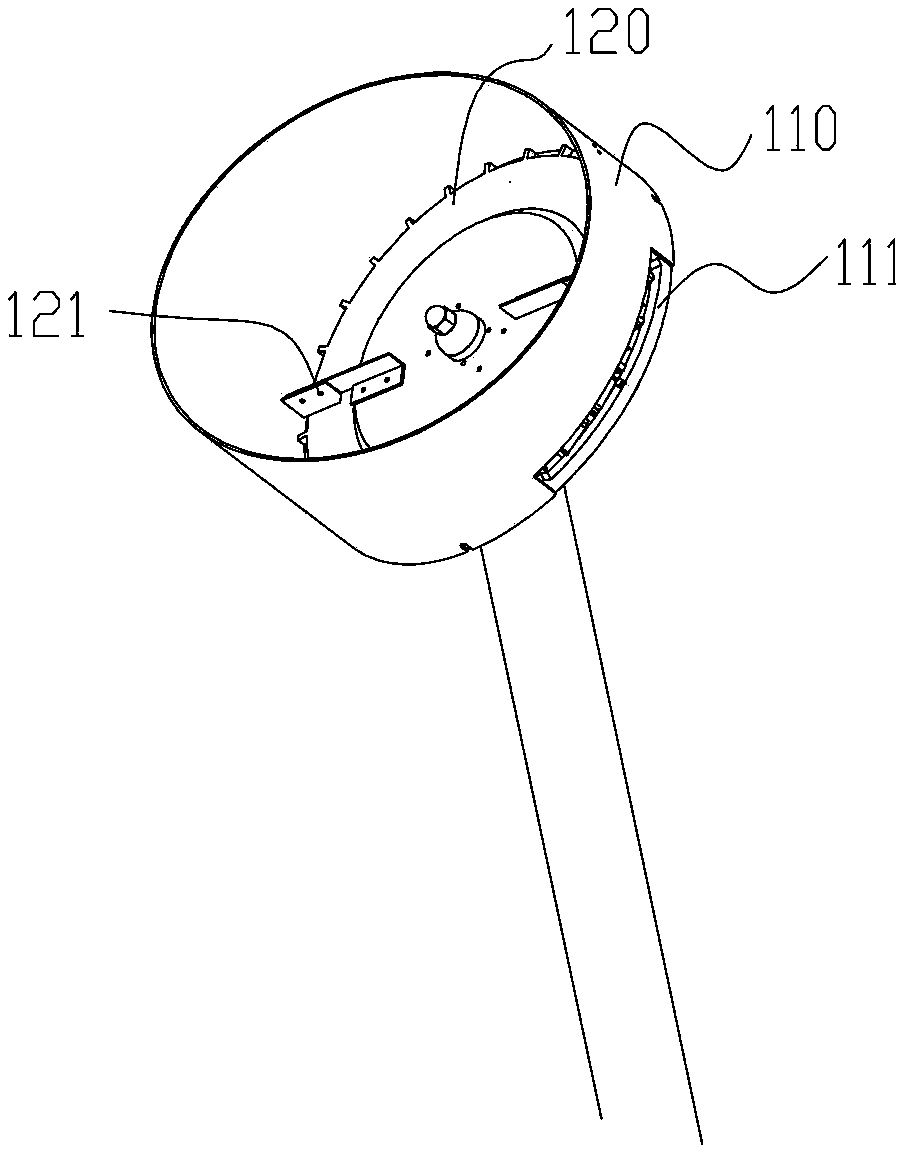

[0027] see figure 1 The first embodiment of a cartridge case detection device of the present invention is shown, including: a mechanical part and an electronic part. The mechanical part includes: a feeding assembly 100, a feeding assembly 200, a visual measurement assembly 300 and a recovery assembly 400, and the feeding assembly 100 and The feeding assembly 200 is connected, the feeding assembly 200 is connected with the visual measurement assembly 300, and the recovery assembly 400 is connected with the visual measurement assembly 300; the electronic part includes: the body camera 5 assembly, the bottom camera 5 assembly and the control unit 12, the control unit 12 and the control unit 12 respectively The missile body camera 5 assembly, the missile bottom camera 5 assembly, the feeding assembly 100, the feeding assembly 200, the visual measurement assembly 300 and the recovery assembly 400 are electrically connected. The body camera 5 assembly includes a body light source 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com