Alignment Slider Assembly

A straightening and sliding block technology, applied in the field of straightening slider assembly, can solve the problems of straightening wheel, straightening wheel shaft wear, high frequency of parts replacement, short straightening cycle, etc., to achieve torsion and straightness Good, low production cost, stable product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

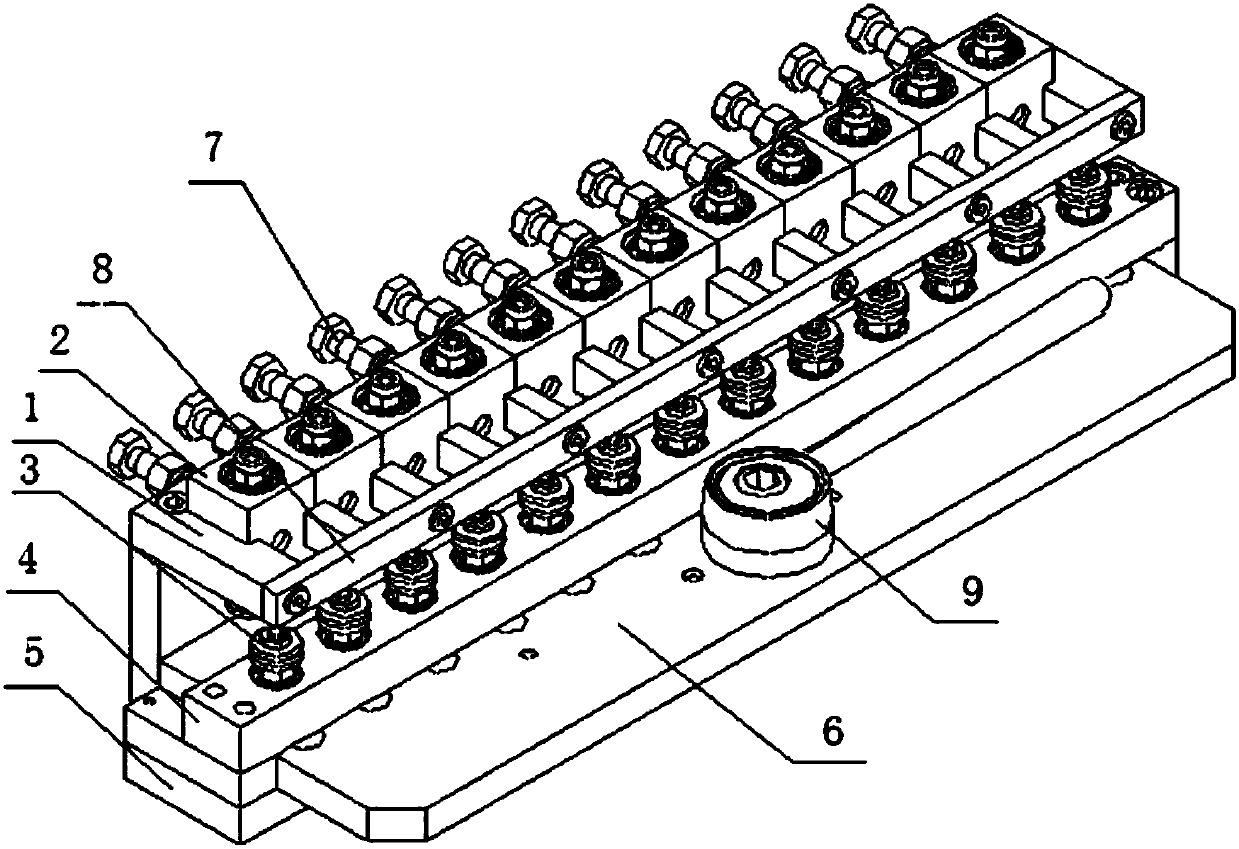

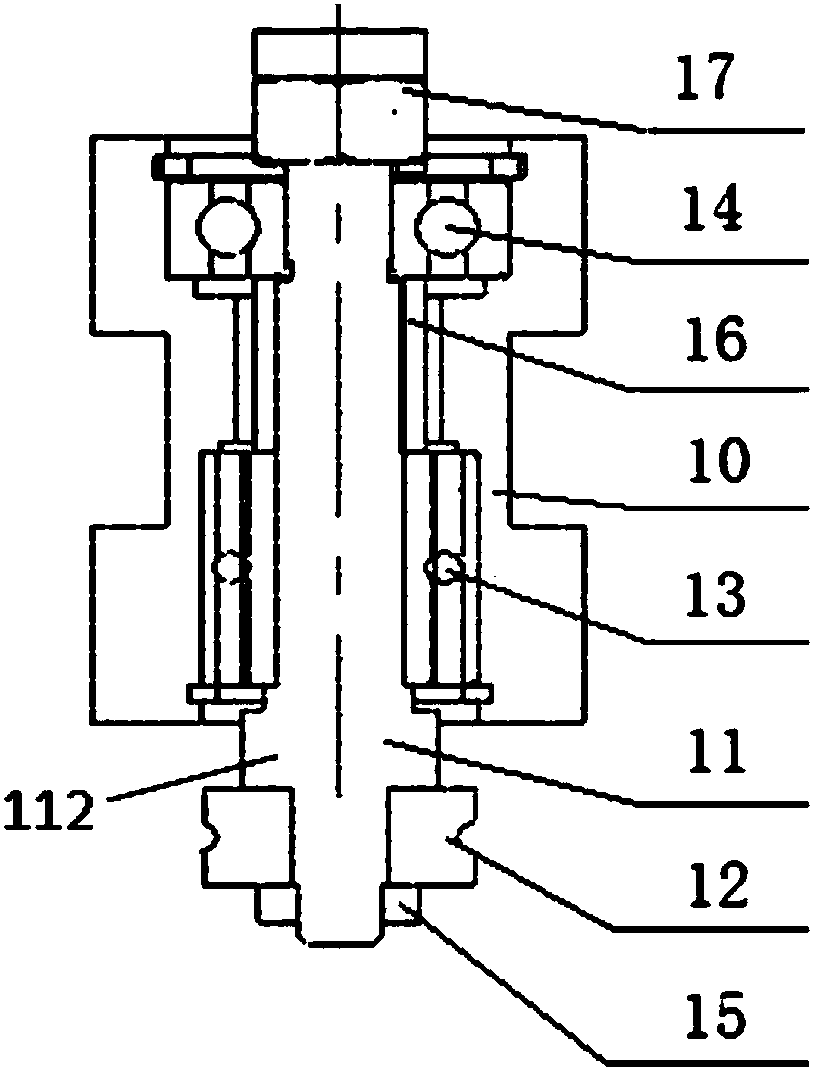

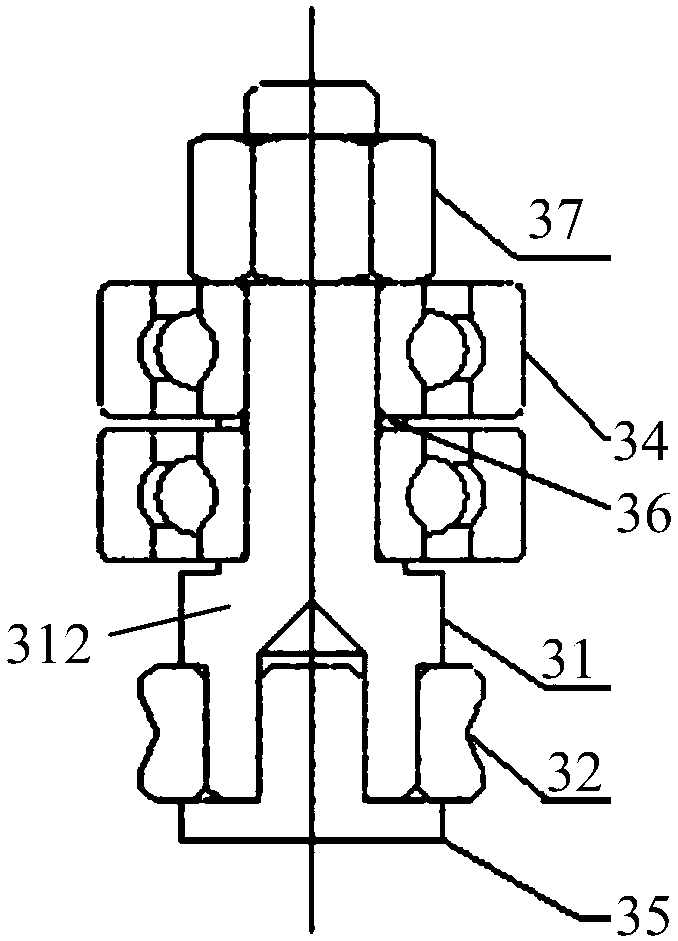

[0019] see figure 1 , figure 2 and image 3 As shown, a straightener for a steel cord retracting machine tool includes an upper press frame 1 and a lower bracket arranged horizontally to each other. An adjusting device 7 for adjusting the distance between the slider assembly 2 and the straightening wheel assembly 3, the adjusting device 7 is the threaded hole provided on one side of the upper pressing frame 1 and the adjusting screw rod assembled therewith, the other of the upper pressing frame 1 The side is also provided with a slider assembly limit baffle plate 8; the lower bracket is provided with thirteen groups of fixed straightening wheel assemblies 3, and the lower bracket includes an upper static slide plate 4, a lower static slide plate 5 and a movable slide plate 6, The upper static slide plate 4 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com