Processing method for welding fixture with complex structure

A welding fixture and complex structure technology, applied in the field of mechanical processing, can solve problems such as inability to guarantee the quality of parts, achieve the effects of strengthening strength, improving processing efficiency, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 A kind of complex structure welding fixture

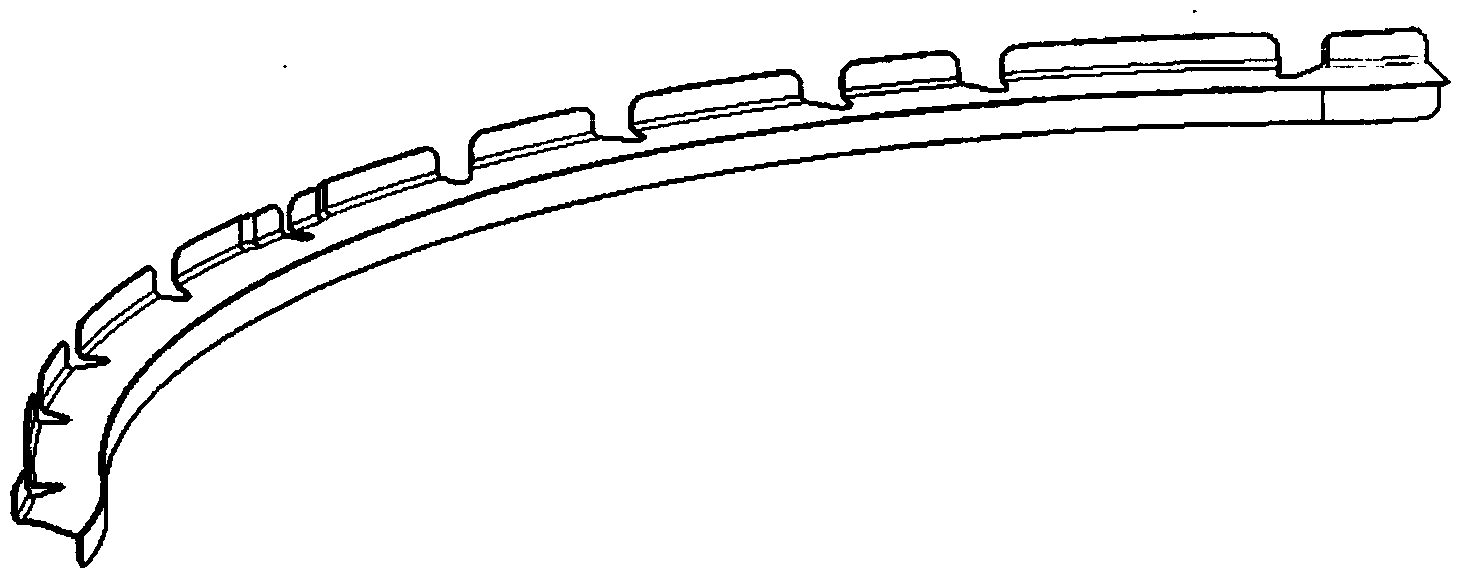

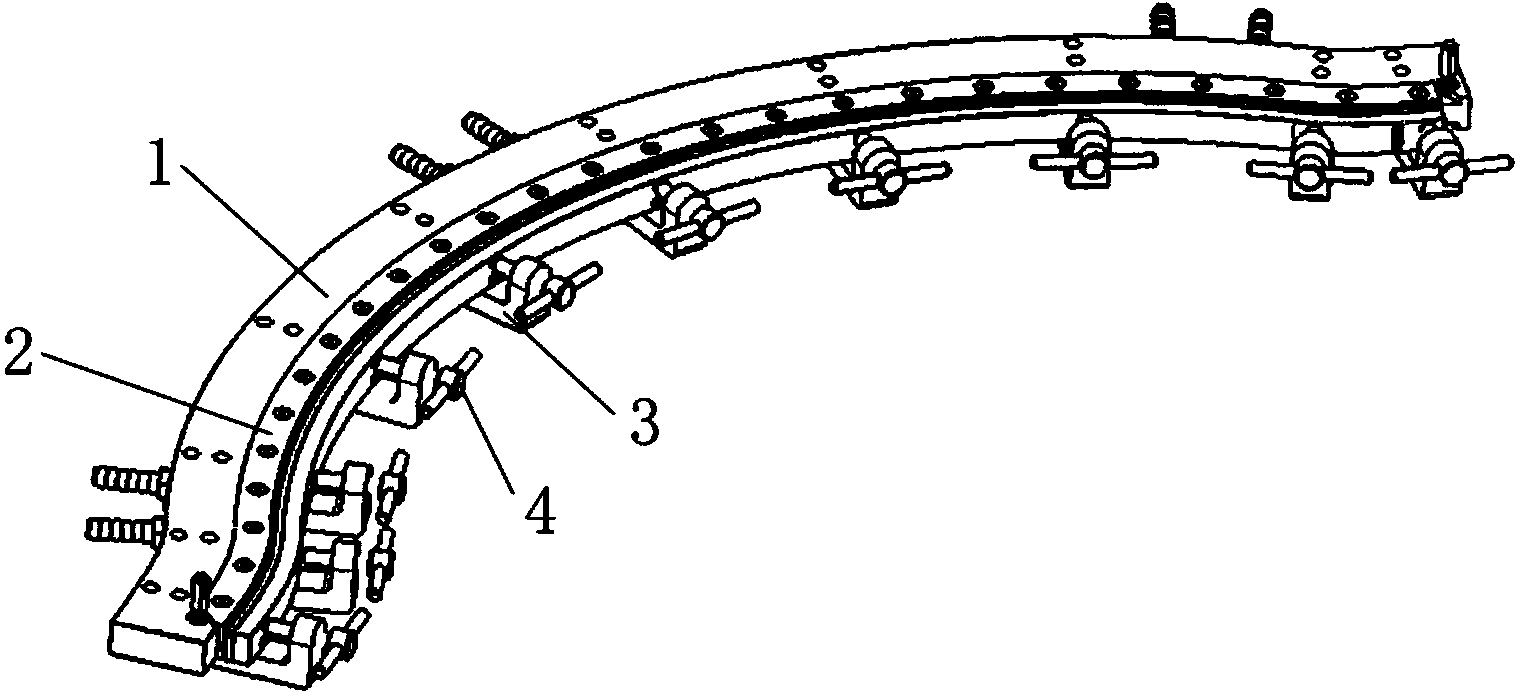

[0018] like Figure 2-4 As shown, a welding fixture with a complex structure includes a main body (1), a copper insert (2), a pressing plate (3) and a pressing screw (4).

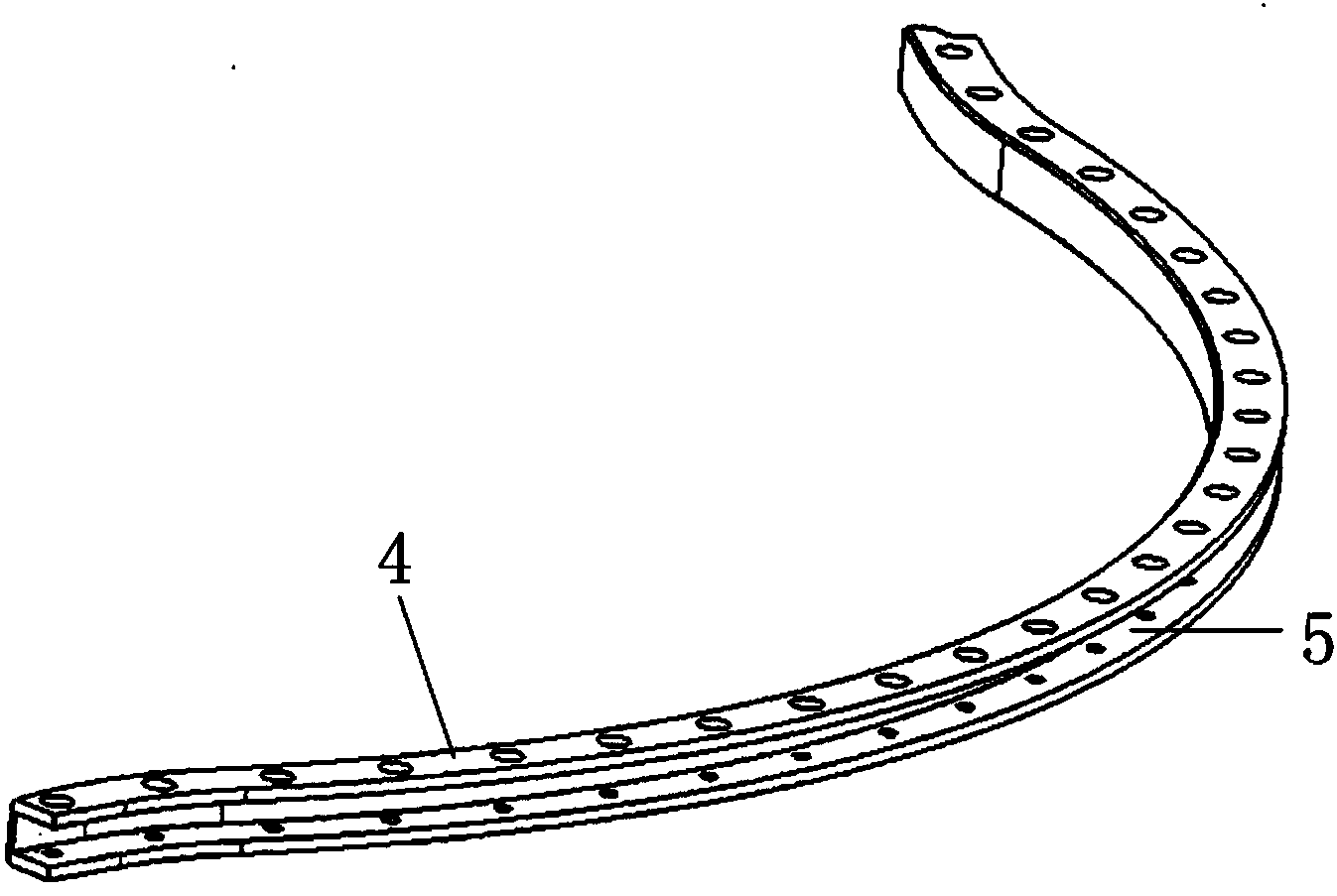

[0019] The section of the red copper insert (2) is a U-shaped structure, one side profile of the main body (1) fits the inner wall of the U-shaped groove (5) of the red copper insert (2), and the pressure plate (3) and the red copper insert (2) ) connection, the compression screw (4) is threaded with the pressure plate (3).

[0020] The wall thickness of the copper insert (2) is 5mm.

Embodiment 2

[0021] Embodiment 2 Processing method of complex structure welding fixture

[0022] (1) Processing of the main body: After the planer processes the thick two sides of the main body (at this time, the thickness of the two sides is thickened by 10mm), the grinder grinds the thick two sides parallel, draws the contour line, and the milling machine processes the shape according to the line, and processes it with the copper insert 3-4mm allowance for CNC machining; after the fitter installs the tool board for CNC machining, use CNC machining for the main body shape, profile, and each step surface, CNC drilling and boring each hole, and then the fitter disassembles the tool board , Polish the surface of CNC machining.

[0023] (2) Processing of copper inserts: planer processes the thick two sides of the copper inserts parallel to each other (at this time, the thickness of the two sides is thickened by 10mm, which is equivalent to the wall thickness of the copper inserts being 10mm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com