Hardcover box automatic rolling foam scraping machine

A hardcover box and fully automatic technology, applied in the field of packaging, can solve the problems of manpower consumption and quality stability cannot be guaranteed, and achieve the effects of improving production efficiency, saving production operators, and compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to deepen the understanding of the utility model, the utility model will be further described below in conjunction with the embodiments and accompanying drawings. The embodiment is only used to explain the utility model, and does not constitute a limitation to the protection scope of the utility model.

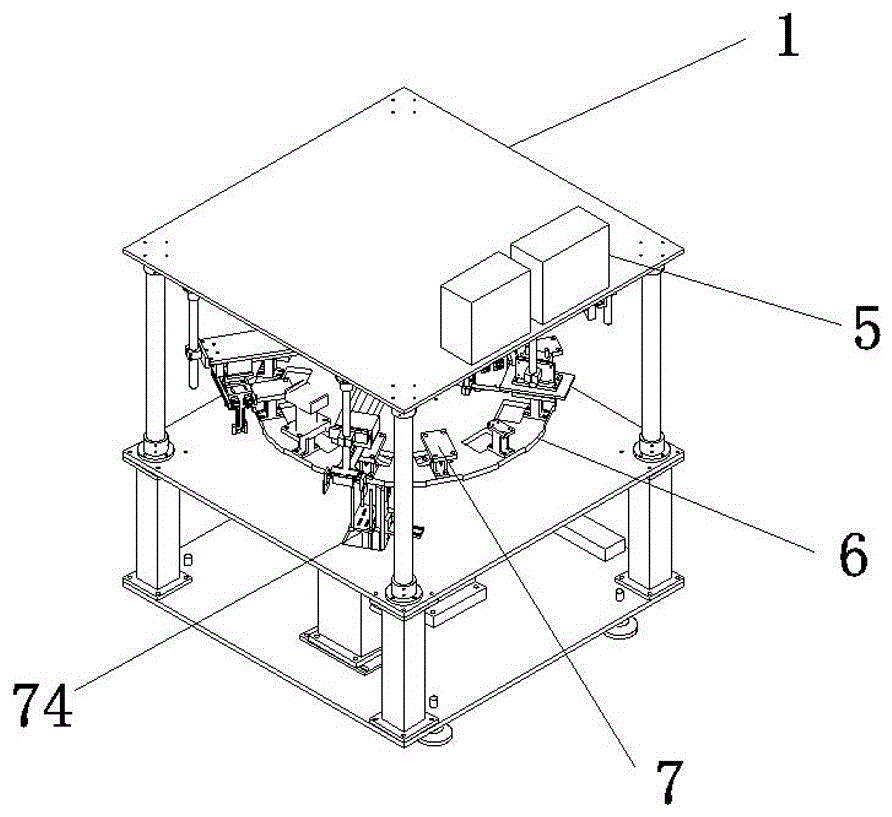

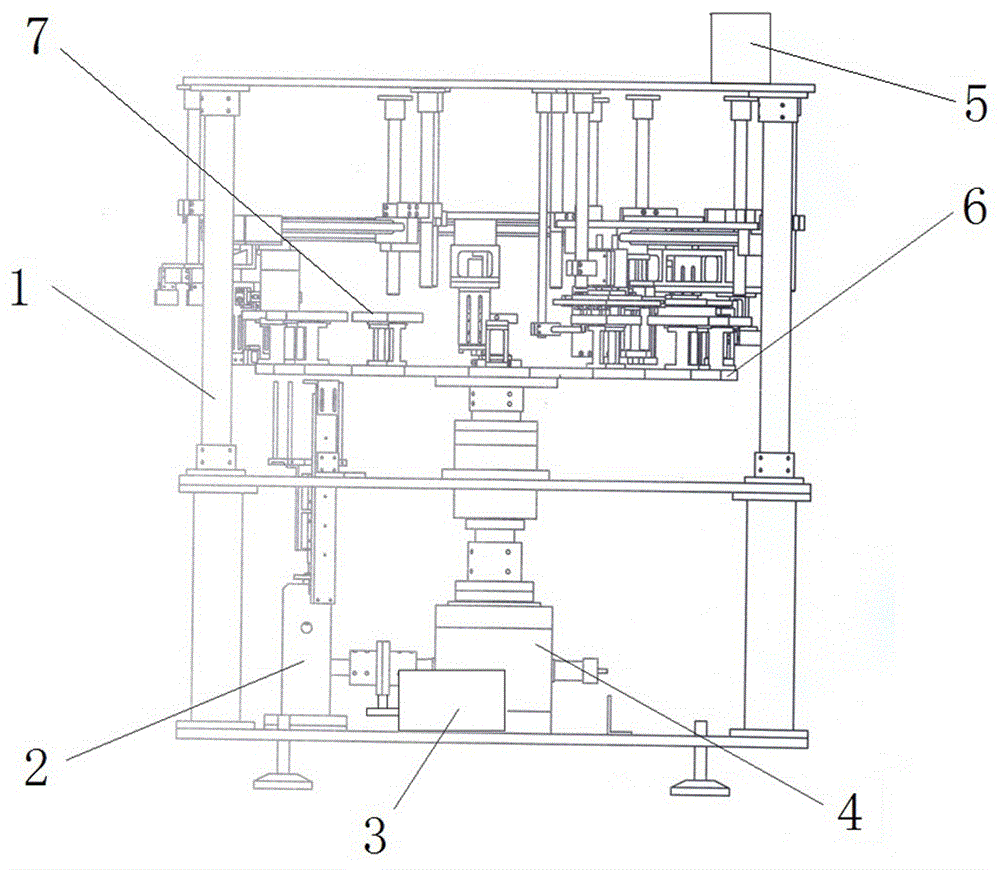

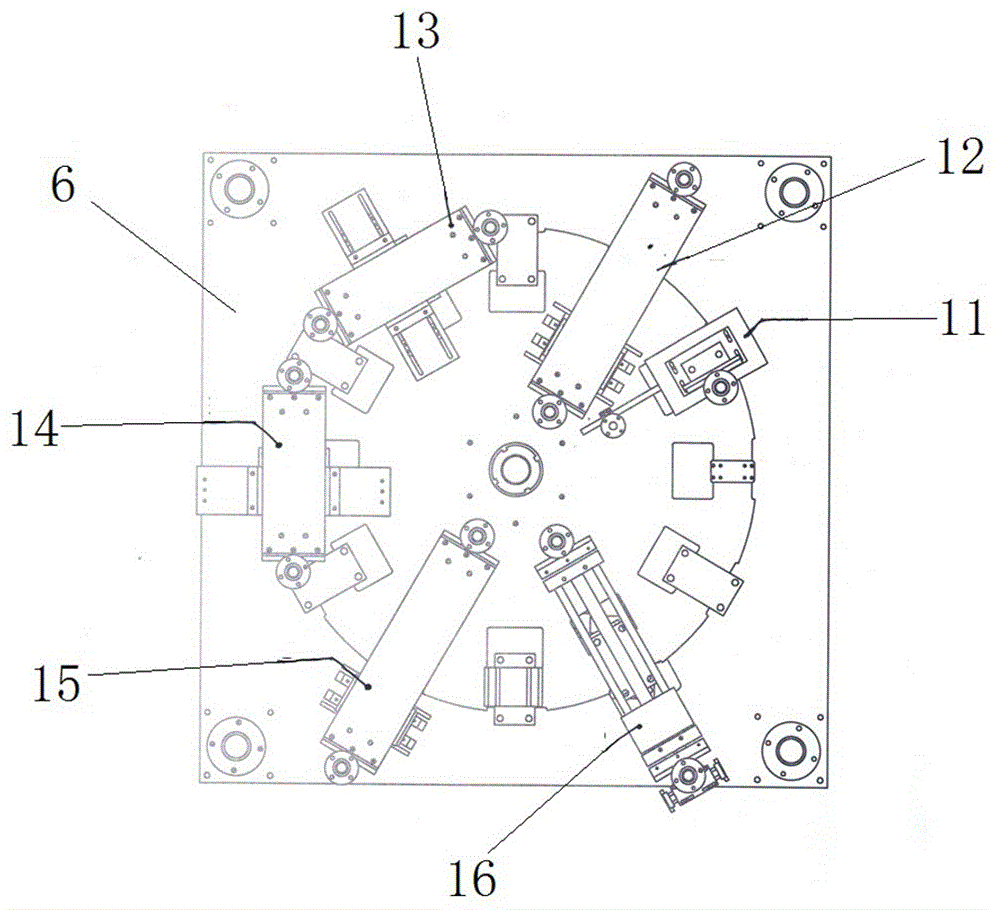

[0023] Figure 1-3 Shown is an embodiment of a full-automatic rolling bubble edge scraping machine for a hardcover box of the present invention, including a frame 1, a worm gear reducer 2, a drive motor 3, a cam divider 4, a control device 5 and a processing turntable 6. The frame 1 is provided with upper and lower layers, and the processing turntable 6 is rotated on the upper layer of the frame 1, and the processing turntable 6 is provided with several processing stations 7 that are evenly distributed along the outer circumference and match the shape of the hardcover box. Located above the processing turntable 6, the corresponding processing station 7 is seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com