Directional rotating guide drilling tool

A rotary steerable drilling and directional technology, which is used in directional drilling, drilling equipment, and automatic drilling control systems, etc., can solve the problems of mandrel fatigue damage, affecting tool life, poor wellbore quality and wellbore condition, etc. Reduce alternating stress, increase service life, and achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

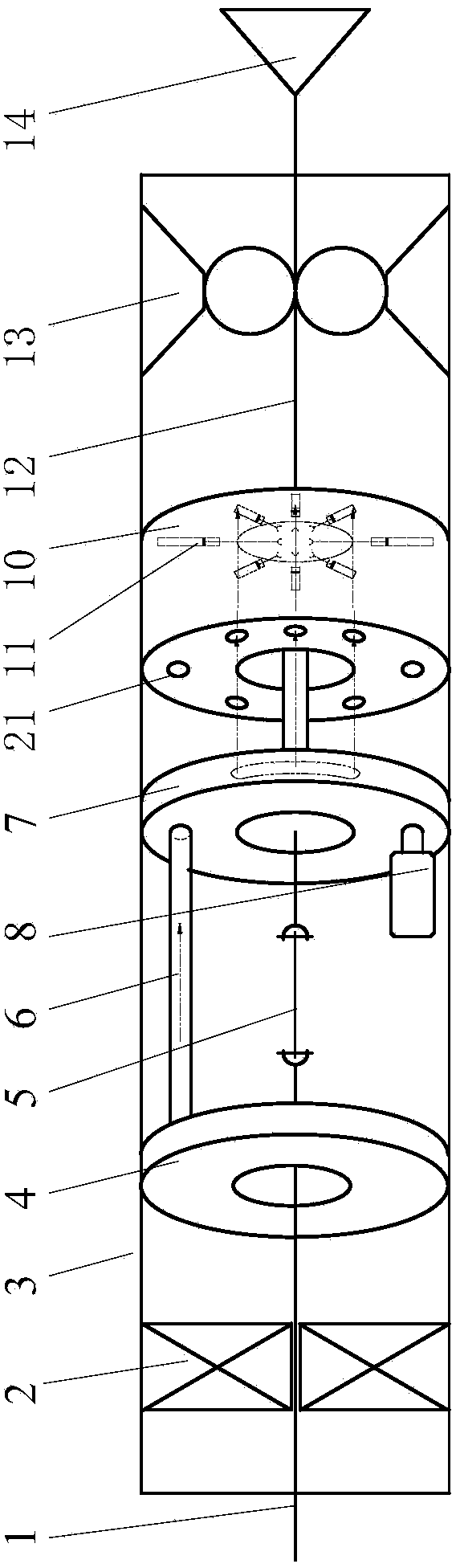

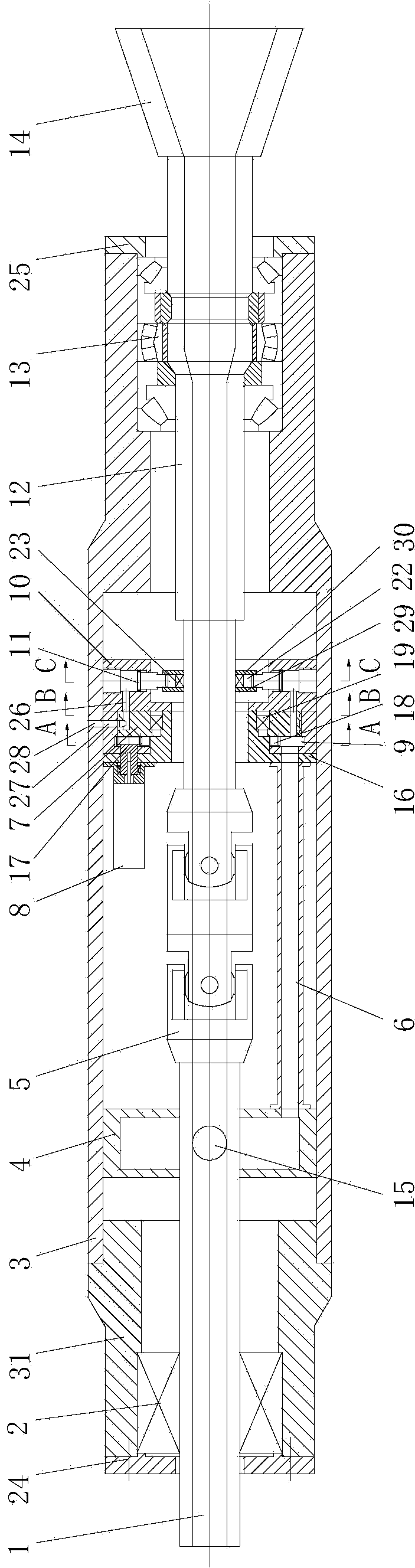

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

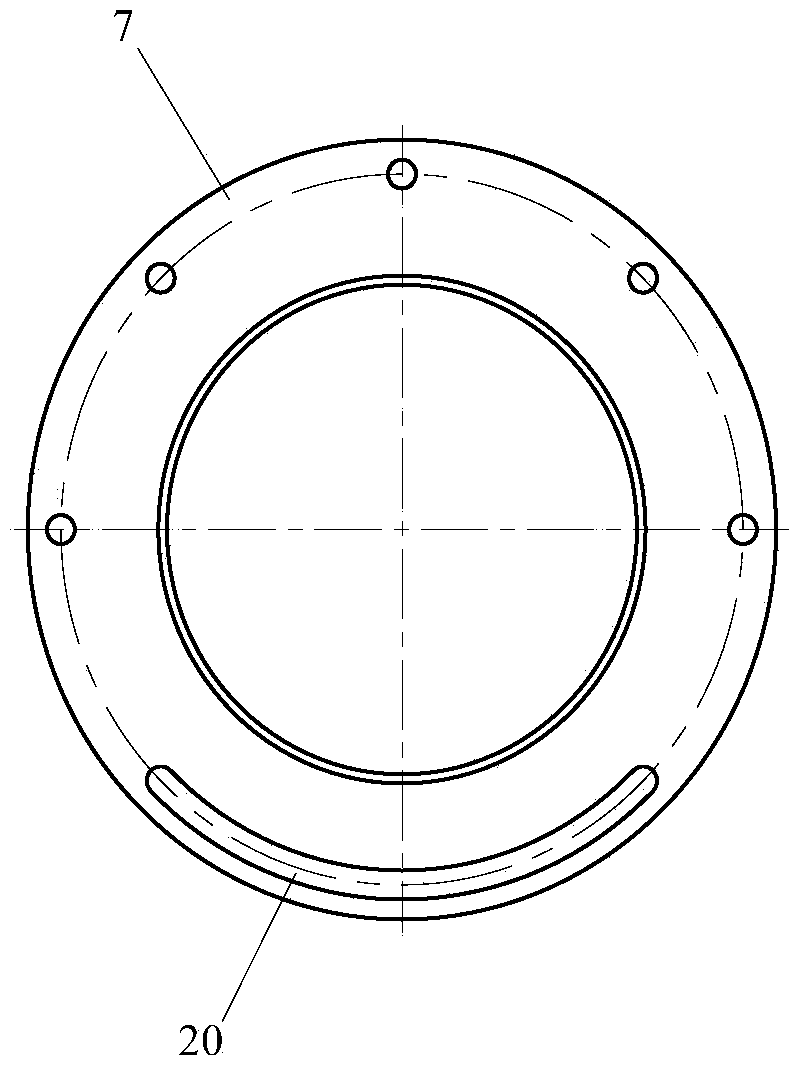

[0026] See Figure 1 to Figure 6 , a pointing rotary steerable drilling tool, including an outer cylinder 3 and a biasing mechanism fixed inside it, the biasing mechanism includes an upper plate valve cover 16 and an integrated Hydraulic cylinder 10; a motor 8 is fixedly connected to the top of the upper plate valve end cover 16, and a high-pressure cavity 9 is fixedly connected to the bottom of the upper plate valve end cover 16, and a high-pressure cavity 9 is provided to rotate with it. The upper disc valve 7 that is tightly connected, the upper disc valve 7 is sleeved on the upper disc valve end cover 16, and the upper disc valve 7 is rotatably connected to the upper disc valve end cover 16 through a bearing 19. The lower surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com