Quick reversing system

A reversing system and fast technology, applied in the fluid pressure actuation system components, valve details, multi-port valves, etc., can solve the problems of poor switching time repeatability, long switching time of the reversing valve, easy gas leakage, etc. Good performance, ensure safety, and reduce the effect of switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

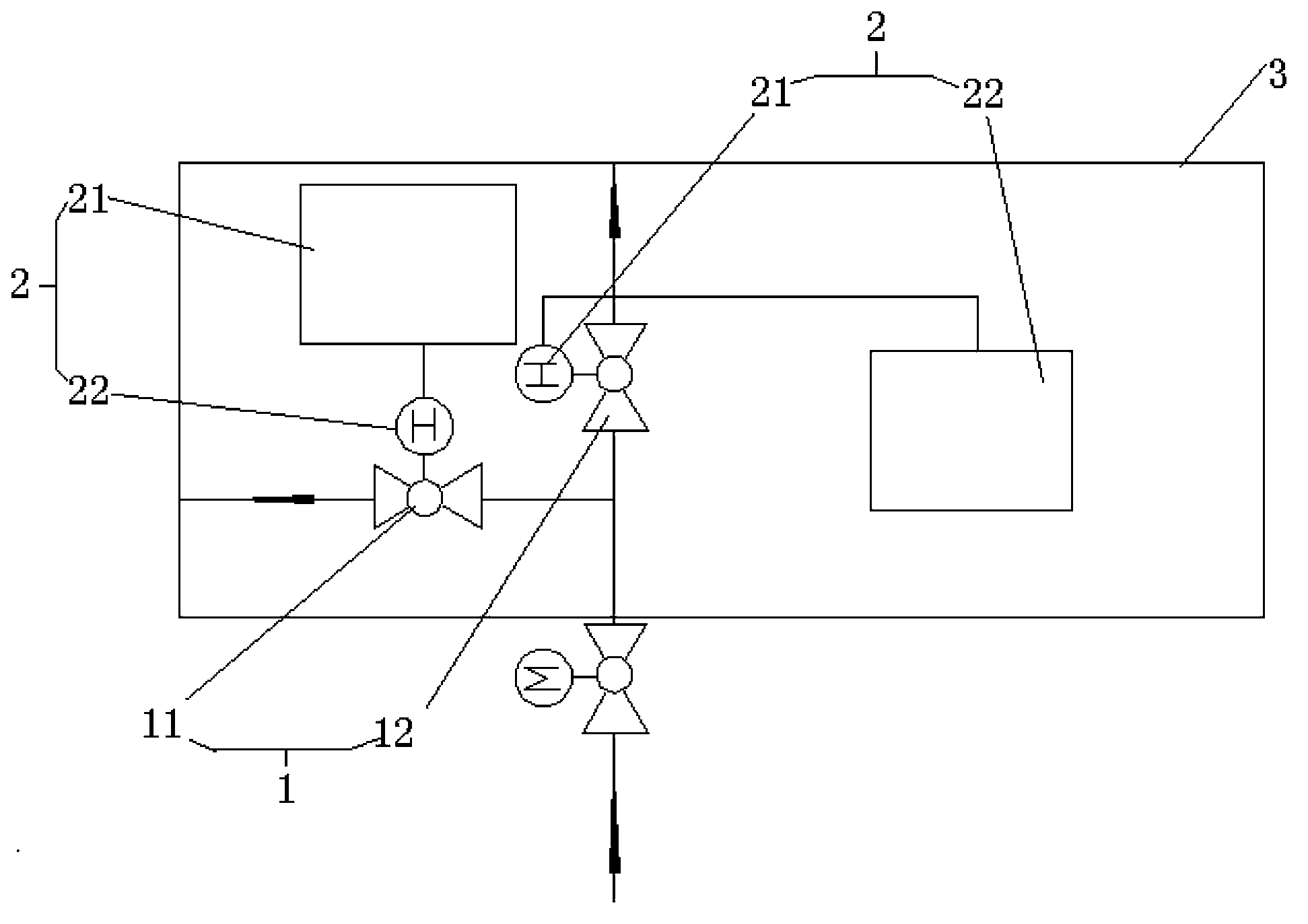

[0022] Such as figure 1 As shown, an embodiment of the present invention provides a rapid reversing system. The rapid reversing system includes: a reversing valve 1, a matching process pipeline 3, and an execution structure 2. The reversing valve 1 adopts a double-off and double-discharge straight-through ball valve, and the executive structure 2 adopts a hydraulic executive structure. The valve stem of the reversing valve 1 is pushed through the independent hydraulic executive structure so that the reversing valve 1 Repeat the switch.

[0023] The embodiment of the present invention adopts a hydraulic actuator structure, that is, the actuator structure 2 adopts a hydraulic drive form, which avoids the compressibility of air, so that the time ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap