Sensor device used for surface parameter detection

A sensor device and sensor array technology, applied in the field of sensing, can solve problems such as inaccurate pressure distribution detection, broken array sensor electrodes, energy loss, etc., and achieve improved acquisition speed, real-time performance, strong immediacy, and less interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

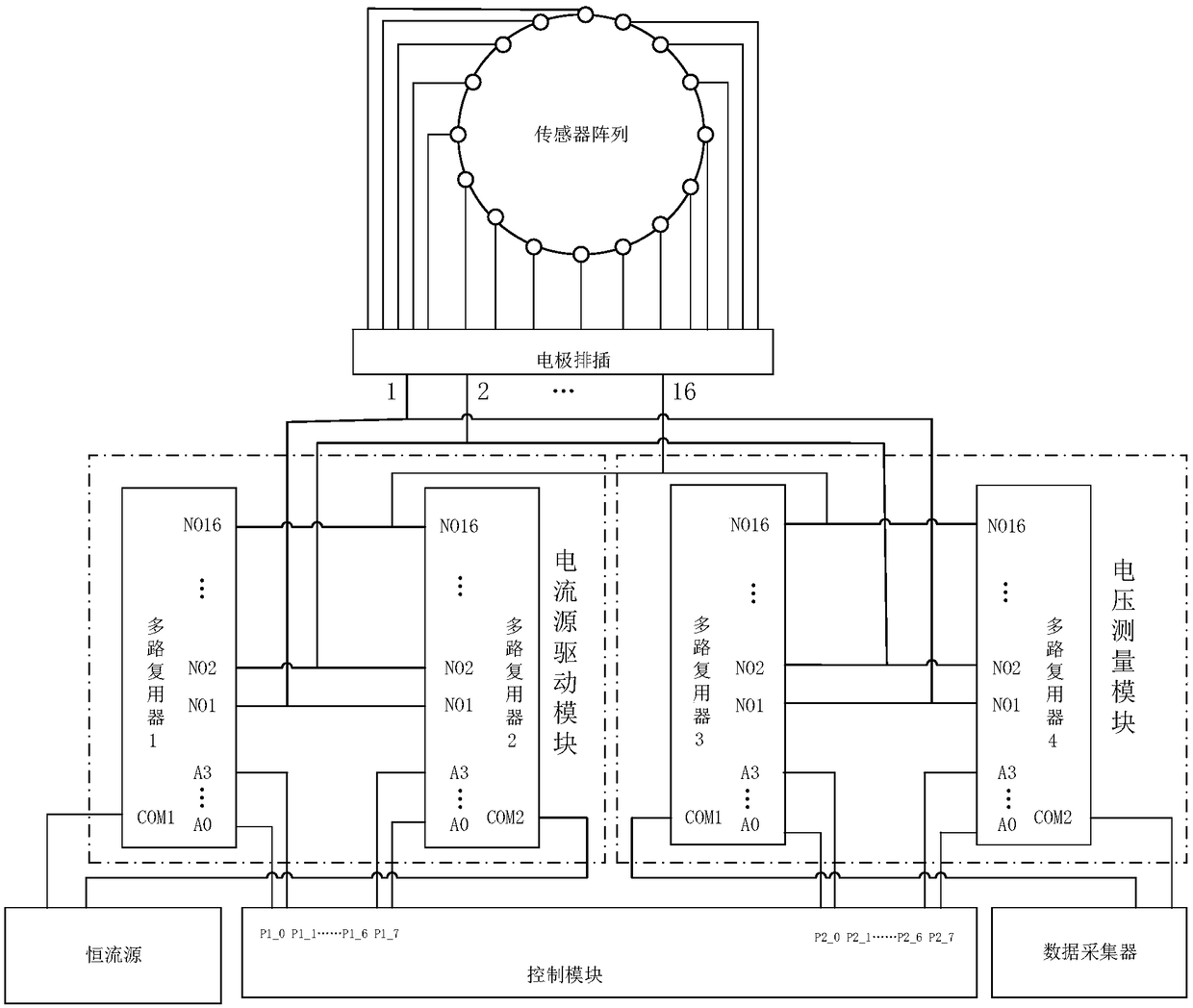

[0022] Such as figure 1 As shown, the sensor device designed in the present invention for surface parameter detection includes a control module, a data collector, a current source drive module, a voltage measurement module, a constant current source, electrode strips and a sensor array, and the control module is connected to the current The source drive module and the voltage acquisition circuit are connected, the current source drive module and the voltage acquisition circuit are connected to the sensor array through electrode strips, the constant current source is connected to the current source drive module, and the data collector is connected to the voltage measurement module.

[0023] The current source drive module includes 2 multiplexers, and each multiplexer is connected to the control module and the electrode socket; the voltage measurement module also includes 2 multiplexers, and each multiplexer Connect with the control module and the electrode socket respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com