Salt-containing waste liquid combustion and heat energy recycling system and process

A technology for recovery of salty waste liquid and heat energy, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of unstable process operation, irregular follow-up, and irregular discharge, etc., to ensure long-term normal operation, Safe effect of avoiding deposition and recovering salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

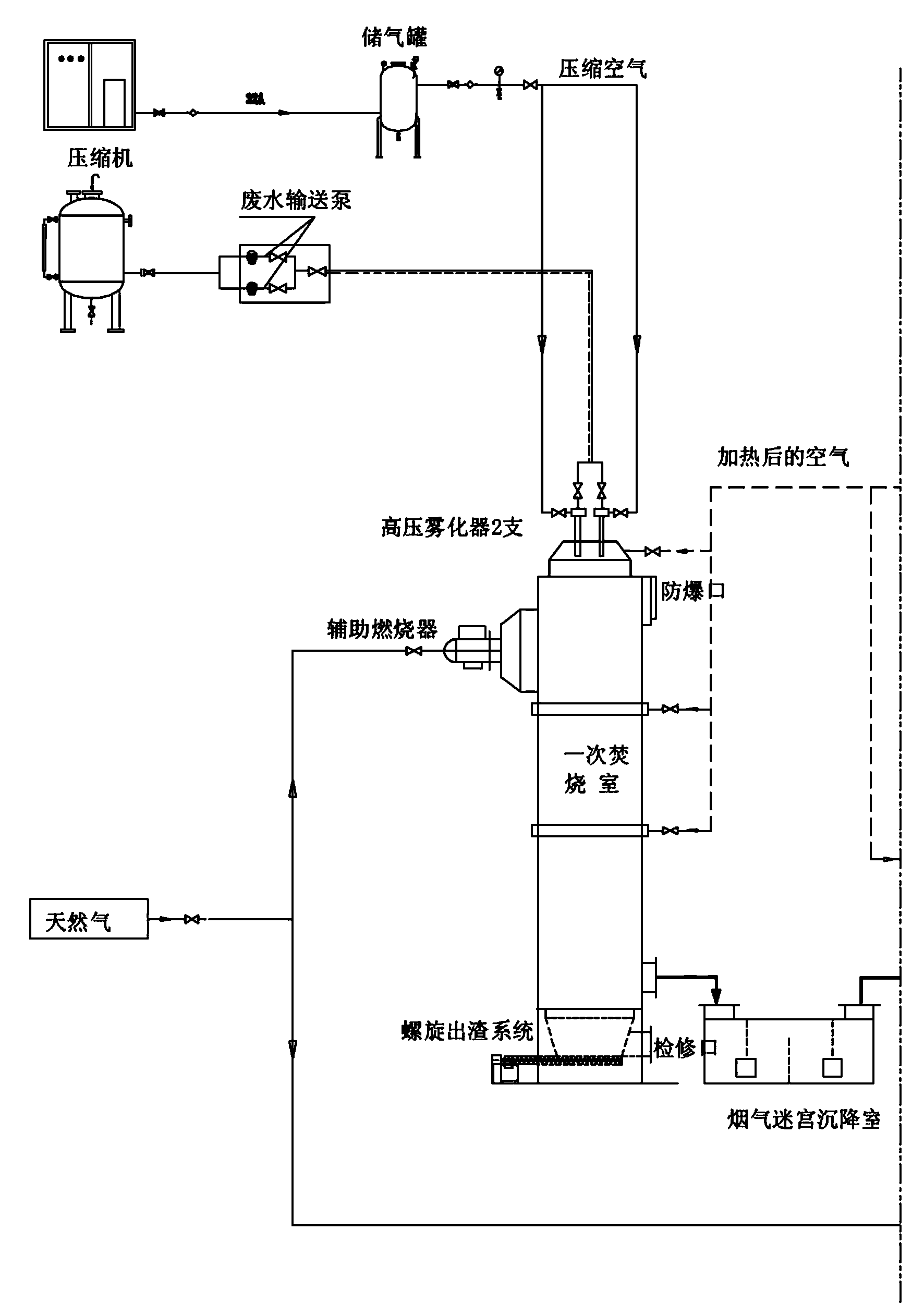

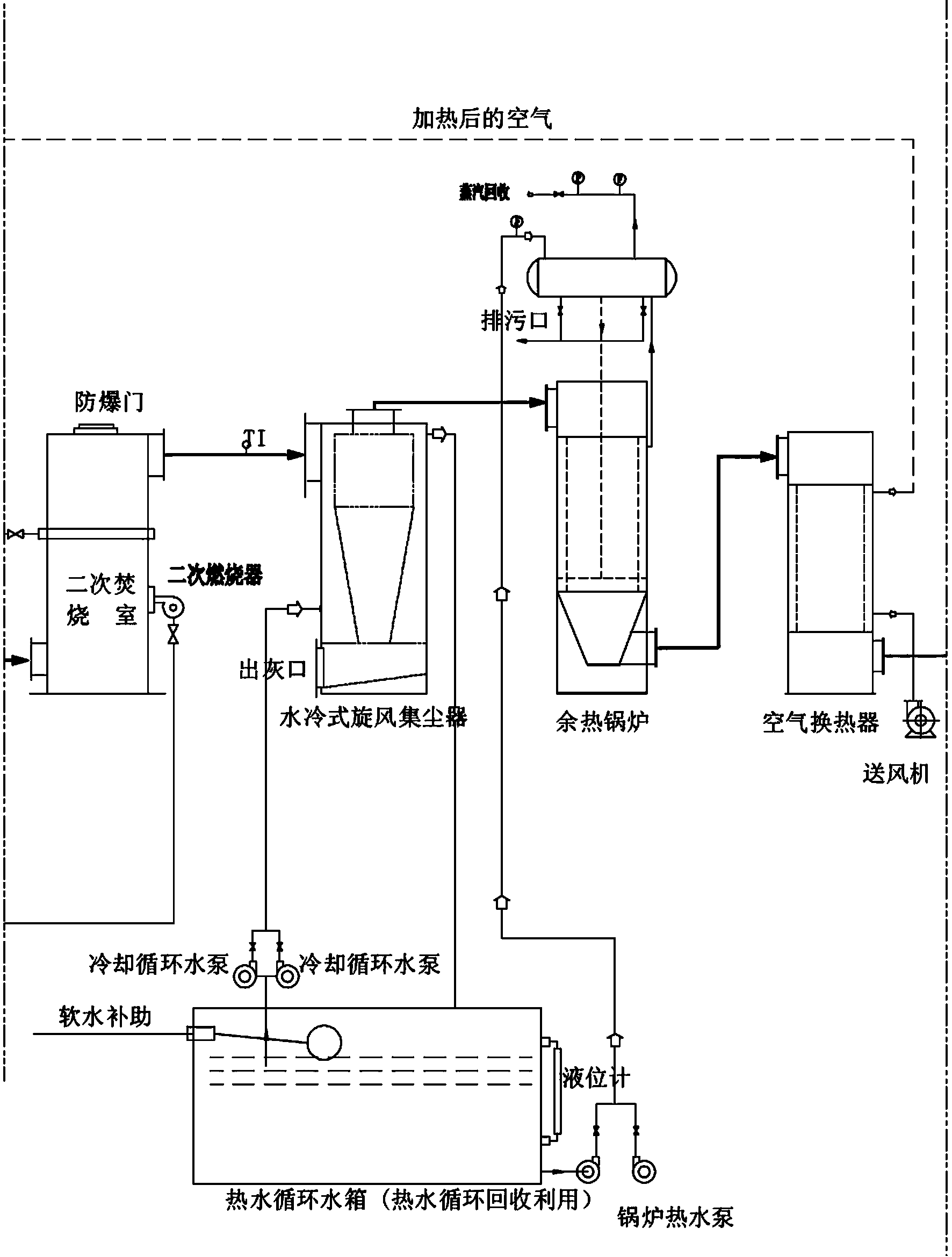

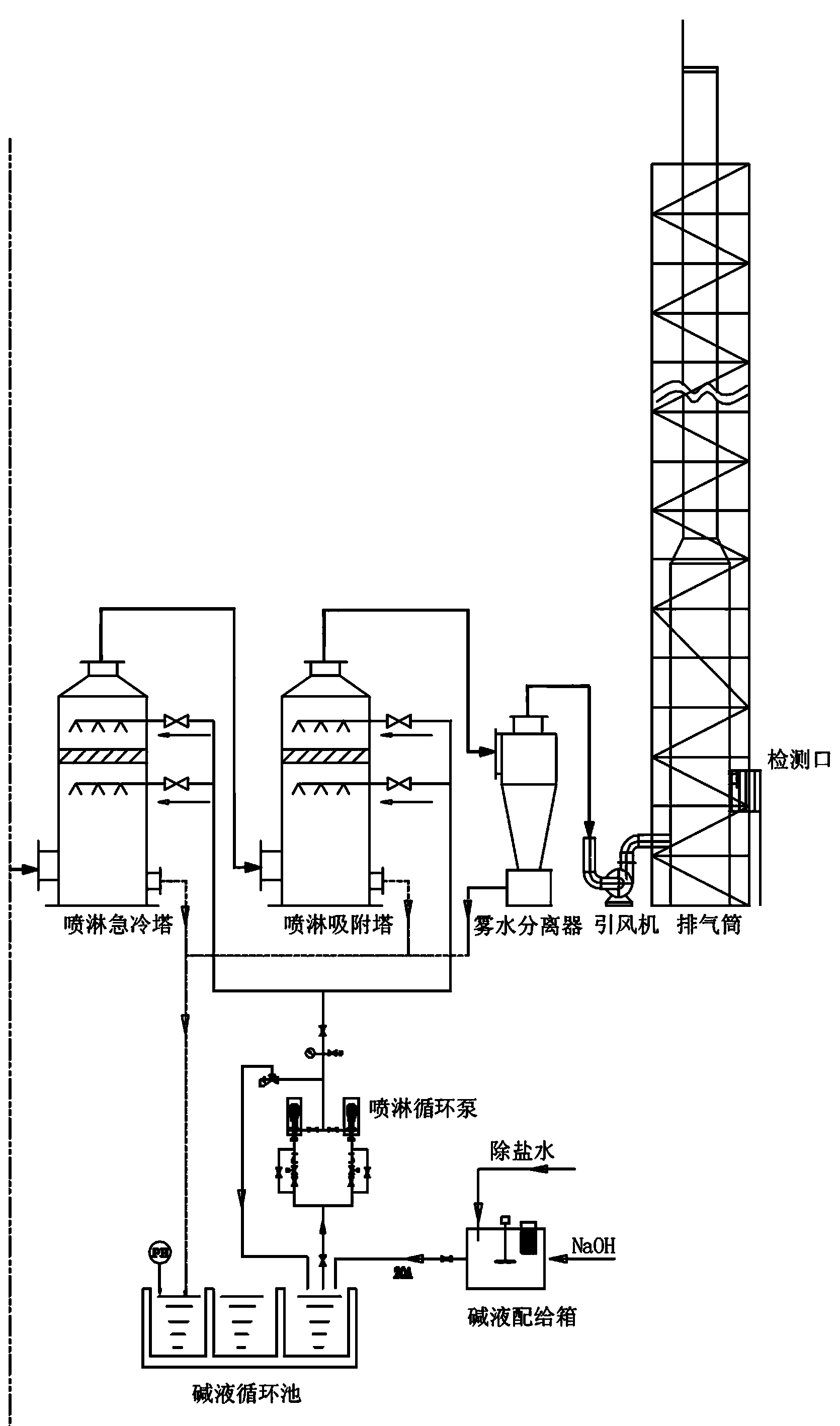

[0037] Such as Figure 1-2 As shown, a saline waste liquid incineration and heat recovery system includes a high-pressure atomization device, a primary incineration chamber, a labyrinth settling chamber, a secondary incineration chamber, a water-cooled cooling dust collector, a waste heat boiler, and an exhaust gas purification device connected in sequence; The labyrinth settling chamber includes a shell, a flue gas inlet and a flue gas outlet, and a plurality of baffles are vertically arranged between the flue gas inlet and the flue gas outlet in the shell, and the baffles are arranged crosswise so that the flue gas passes through a labyrinthine tortuous route; The length, width and height of the labyrinth settling chamber are set according to the amount of flue gas produced by the calorific value of the incinerated waste liquid, so that the flow velocity of the flue gas in the labyrinth settling chamber is 2-3 m / s, and the flue gas flows in the labyrinth The residence time i...

Embodiment 2

[0043] Such as figure 2 As shown, a saline waste liquid incineration and heat recovery process specifically includes the following steps:

[0044] 1) The saline waste liquid is atomized under high pressure and mixed with air and then enters the primary incineration chamber for incineration treatment; the temperature of the primary incineration is 750-800°C, and the residence time of the atomized waste liquid in the primary incineration chamber is 2 seconds;

[0045] 2) The flue gas produced in the primary incineration chamber is introduced into the labyrinth-type settling chamber for sedimentation treatment to remove large particles of salt particles and dust in the flue gas; the flue gas after primary incineration passes through the labyrinth-type settling chamber at 2.5 m / s The second speed passes, and the residence time of the flue gas in the settling chamber is controlled at 2 seconds.

[0046] 3) The residual flue gas after step 2) is introduced into the secondary incin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap